High pressure resistant temperature sensor

A technology of temperature sensor and high voltage resistance, which is applied in thermometers, thermometers and instruments with direct heat-sensitive electric/magnetic components, etc., which can solve the problems of high operating temperature, difficult maintenance, short service life, etc., and achieve good insulation performance , good safety and reliability, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0021] The present invention provides a high pressure resistant temperature sensor, including:

[0022] insulating film;

[0023] The thin film thermistor part is formed on the surface of the insulating film with a thermistor material;

[0024] a pair of electrodes formed on the insulating film and connected to the thin film thermistor;

[0025] Wherein, the insulating film is made up of the following materials by weight:

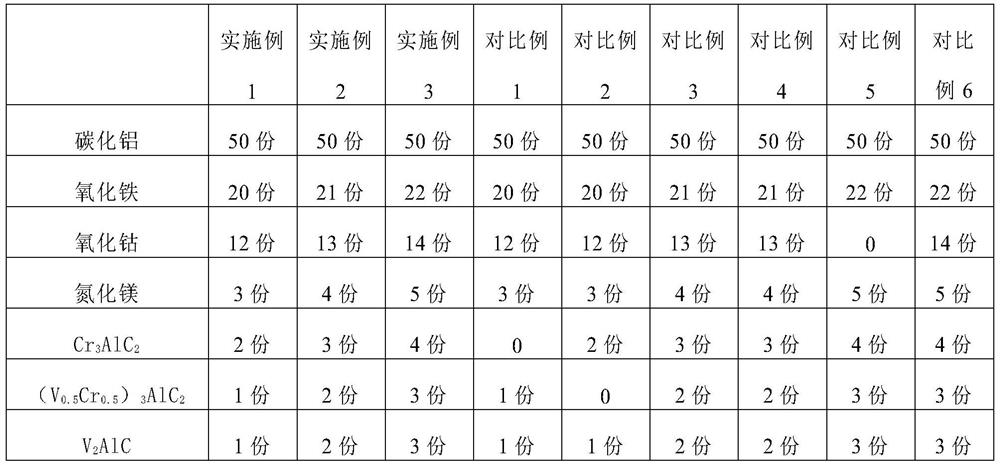

[0026]

[0027] Aluminum carbide, as the main body of the insulating film, has high heat resistance and good thermal stability; iron oxide, cobalt oxide, and magnesium nitride as a whole, synergistically improve its aging resistance, fire resistance, corrosion resistance and moisture resistance.

[0028] As yet another embodiment of the present case, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com