Three-dimensional layered Co-Al double hydroxide composite material and preparation method and application thereof

A hydroxide and composite material technology, applied in the analysis of materials, material resistance, material analysis by electromagnetic means, etc., can solve the problem of high cost of sensors, achieve improved sensitivity, high gas sensitivity and response speed, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0033] Embodiment 1: In this embodiment, the three-dimensional layered CoAl double metal hydroxide composite material is made of cobalt nitrate, aluminum nitrate, ammonium fluoride and a precipitating agent; the precipitating agent is an aqueous urea solution.

[0034] This embodiment has the following beneficial effects:

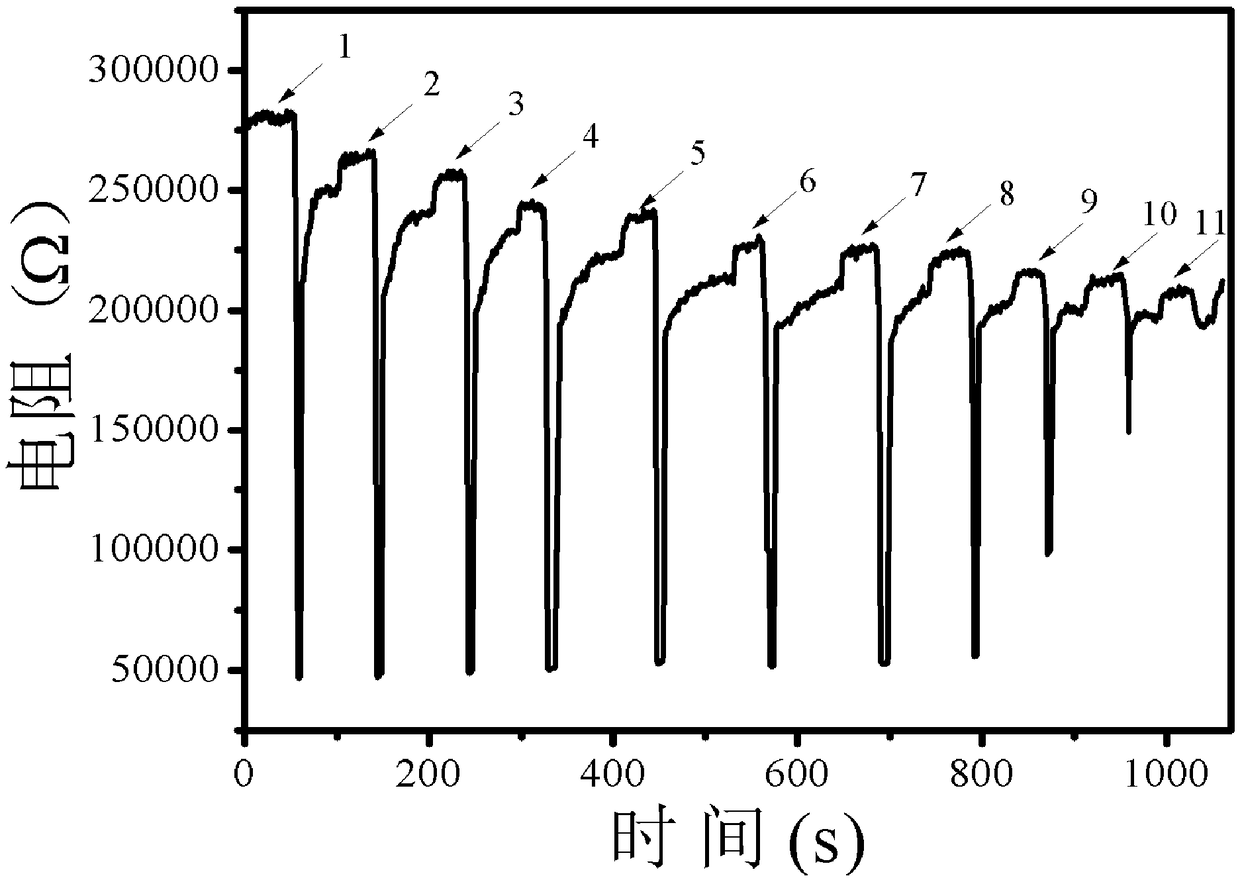

[0035] 1. The three-dimensional layered CoAl double metal hydroxide composite material in this embodiment has a rich layer structure, and the layers form a flower-like composite material. The flower-like layered double metal hydroxide has a larger specific surface area and can provide more There are more active sites to react with gas molecules, and there are certain pores between the flower-like layered double hydroxide layers, which is conducive to the gas molecules entering into it for reaction; therefore, the flower-like layered bimetallic hydroxide The hydroxide nanostructure has higher gas sensitivity and response speed, which can improve the sensitiv...

specific Embodiment approach 2

[0039]Embodiment 2: This embodiment differs from Embodiment 1 in that the molar ratio of cobalt nitrate to aluminum nitrate is (1-4):1. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the molar ratio of aluminum nitrate to ammonium fluoride is 1: (5-15). Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com