An N-type crystalline silicon solar cell based on doped polysilicon germanium thin film and a preparation method thereof

A technology of polycrystalline silicon germanium and solar cells, which is applied in the field of solar cells, can solve the problems of substrate quality degradation, tunneling oxide layer damage, and affecting the passivation effect of the silicon substrate surface, etc., to achieve improved fill factor, high open circuit voltage and filling Factor, to achieve the effect of selective collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

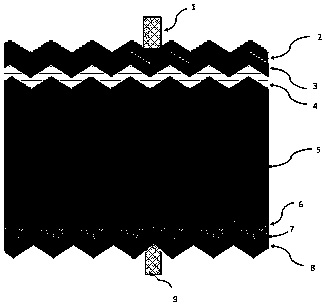

[0030] Such as figure 1 Shown: the present invention relates to an N-type crystalline silicon solar cell based on a doped polycrystalline silicon germanium thin film, which includes a front surface metal gate electrode 1, a front surface silicon nitride anti-reflection film 2, an emitter passivation film 3, and a front surface boron Doped emitter 4, N-type crystalline silicon substrate 5, tunnel oxide layer 6 on the back surface, N+ silicon germanium film 7 on the back surface, anti-reflection film 8 on the back surface, and metal gate electrode 9 on the back surface.

[0031] The preparation method of the present invention comprises the steps of:

[0032] Firstly, conventional texturing is performed on N-type crystalline silicon, and textured structures appear on both the front surface and the back surface of the crystalline silicon substrate after texturing. Then perform standard RCA cleaning on the textured substrate to remove organic contamination and metal particles on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com