Radiofrequency ultrasonic knife with replaceable blade tube

An ultrasonic scalpel and radio frequency technology, applied in the field of radio frequency ultrasonic scalpel, can solve the problems of increasing the amount of medical waste, waste of resources, and high learning costs, and achieve the effects of avoiding secondary cross-infection, improving utilization efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

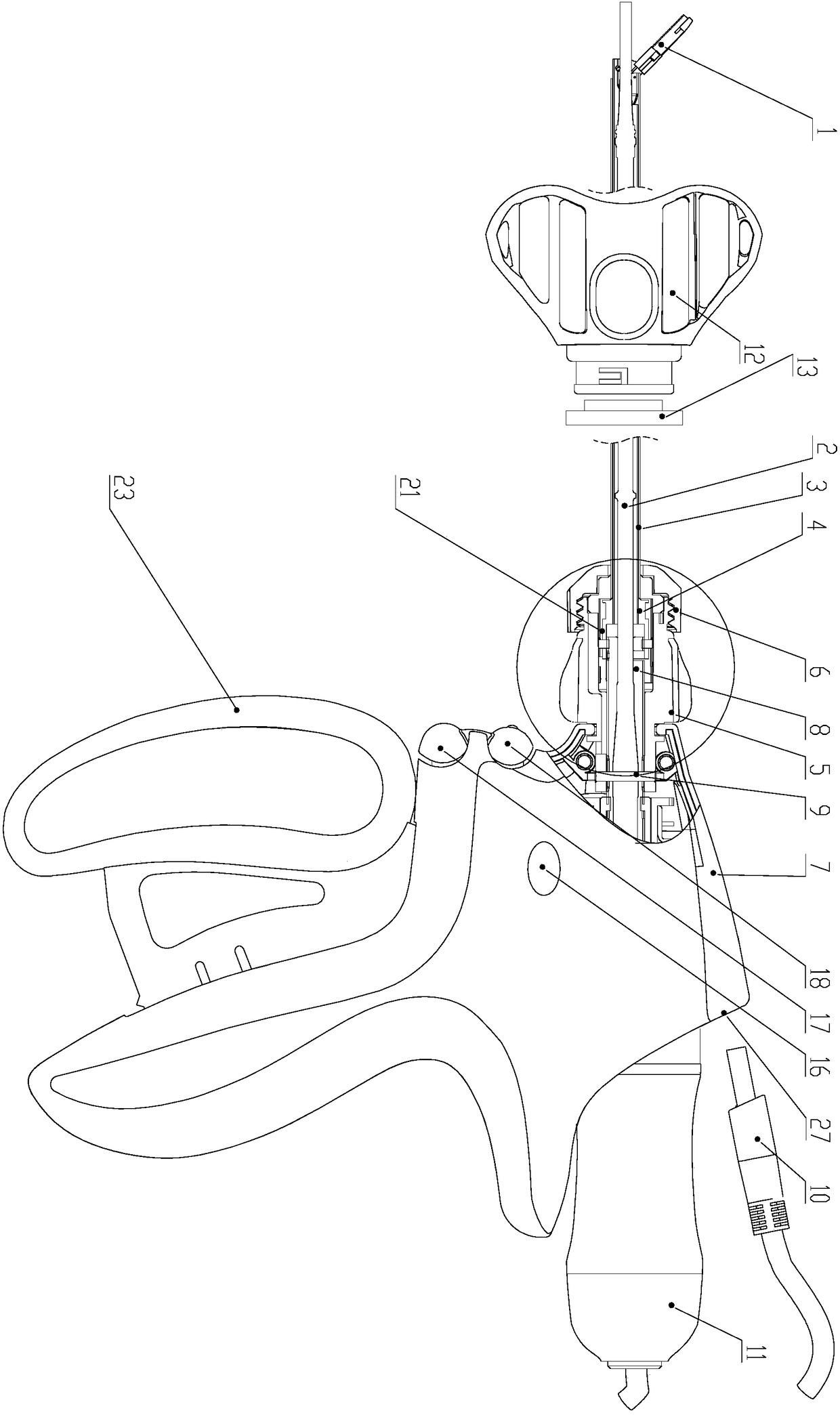

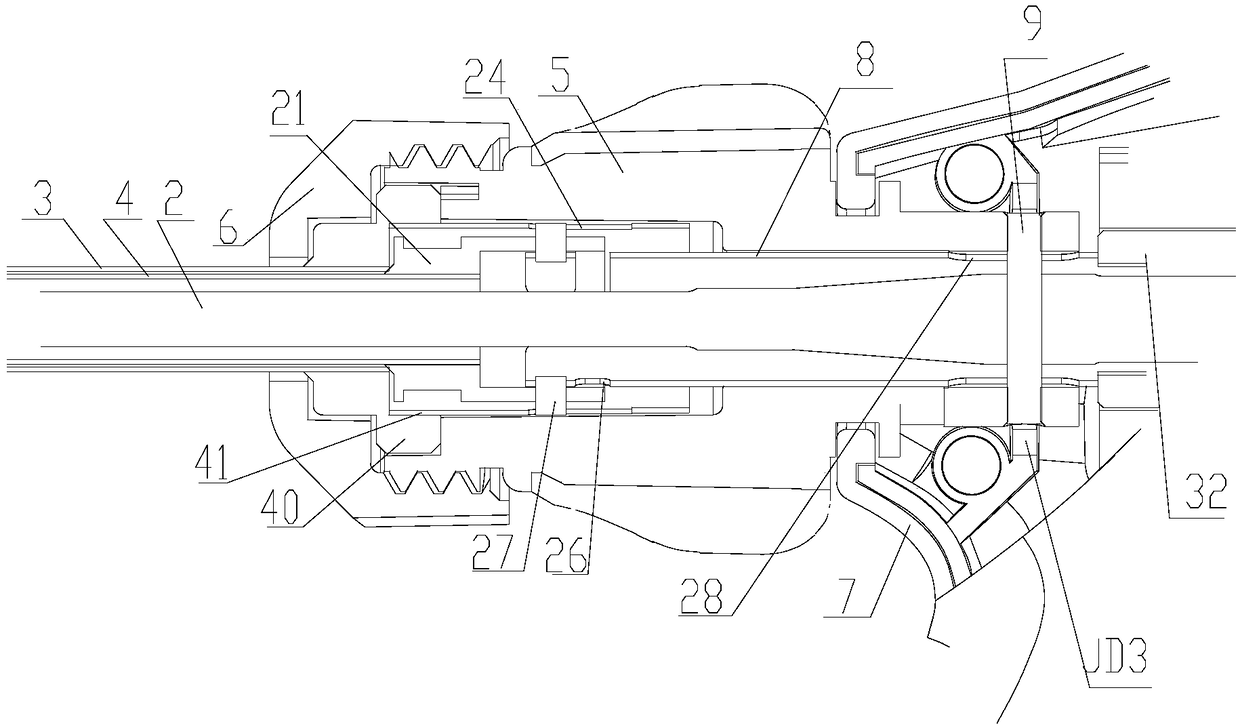

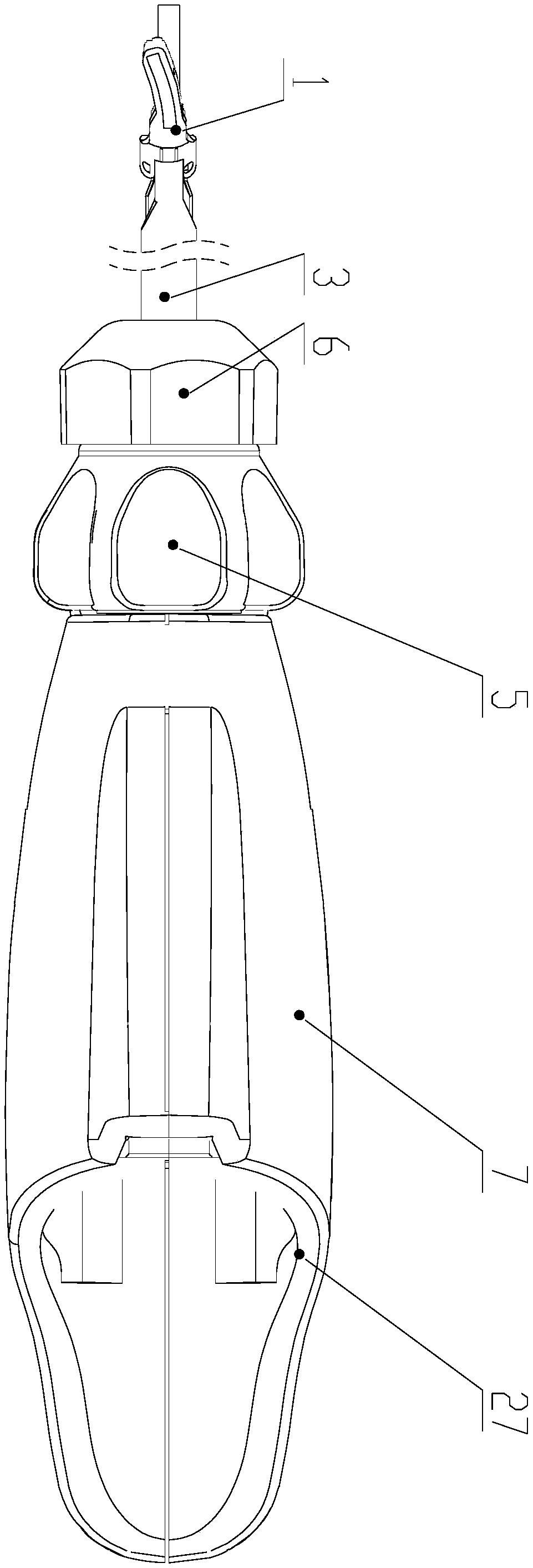

[0089] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 11 It can be seen that a radio frequency ultrasonic knife that can quickly replace the knife tube includes a knife tube assembly 22, a hook pipe 8, an ultrasonic knife handle 7, a radio frequency plug (with wires) 10, a transducer (with wires) 11, a torque wrench 12, Torque wrench conversion device 13. Wherein the knife tube assembly 22, the drag hook pipe fitting 8, and the pin 9 are all made of medical stainless steel through mechanical processing. The cutter bar 2 is made of titanium alloy material through machining. The pliers head 1 is embedded with a polytetrafluoro pad and made of polytetrafluoro material through machining or molding. Ultrasonic knife handle 7, radio frequency plug 10, torque wrench 12, torque wrench conversion device 13, radio frequency button switch 16 (both sides), ultrasonic button 17, radio frequency plus ultrasonic button 18, hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com