Artificial blood vessel supporting mold made through laser carving method

A mold and blood vessel technology, applied in the field of supporting molds prepared by laser engraving, can solve the problems of low frame precision, large size, expensive printing equipment, etc., and achieve the effect of simple structure, strong practicability, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

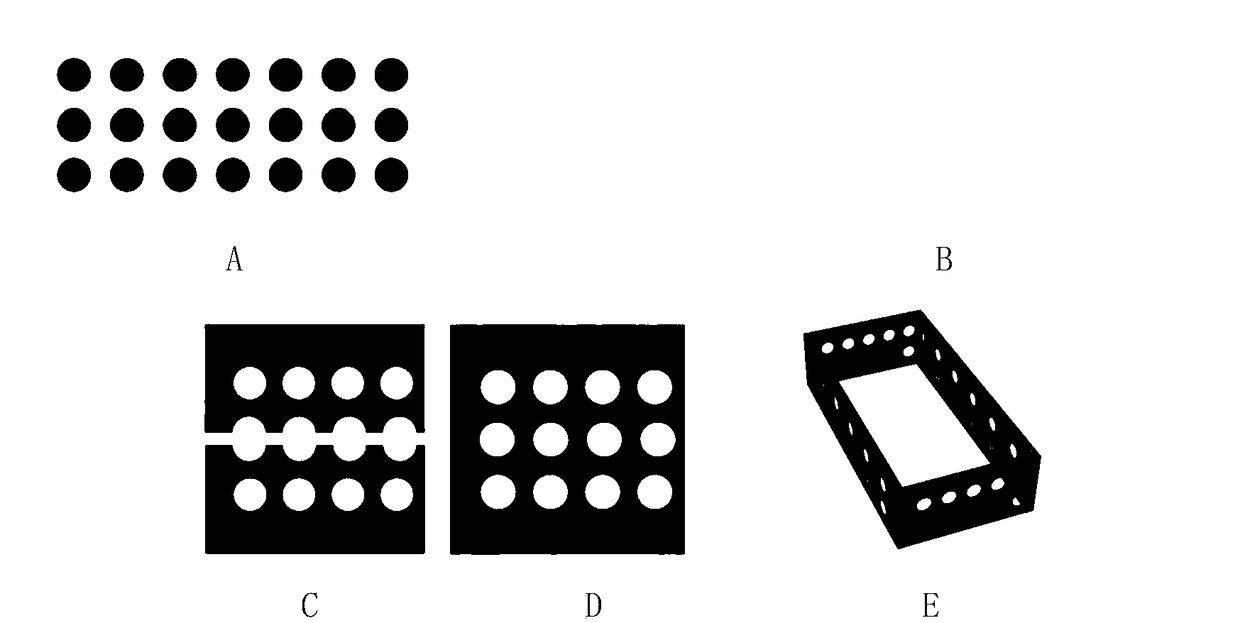

[0042] A support frame mold suitable for artificial blood vessel culture of different diameters, comprising: a mold body, the mold body is a hollow cavity, the hollow cavity is composed of a bottom surface and a side surface, and the side surface is composed of a hole passing through the center point of the hollow cavity The cross section is divided into side I and side II, the side I is provided with at least one through hole, and the side II is respectively provided with at least two through holes, such as figure 1 shown.

[0043] The concrete method of adopting laser engraving method to prepare above-mentioned mold is as: adopting polymethyl methacrylate (PMMA) as mold material, adopting computer design software coredraw to design the long side dimension of mold is 1cm * 4cm, and short side dimension is

[0044] 1cm×2cm, using chloroform as the adhesive, with a thickness of 1mm. After the combination of the short sides is the width of the mold, there are 5 holes arranged s...

Embodiment 2

[0046] The mold of embodiment 1 is used for biomechanical detection of artificial blood vessels in vitro, specifically including:

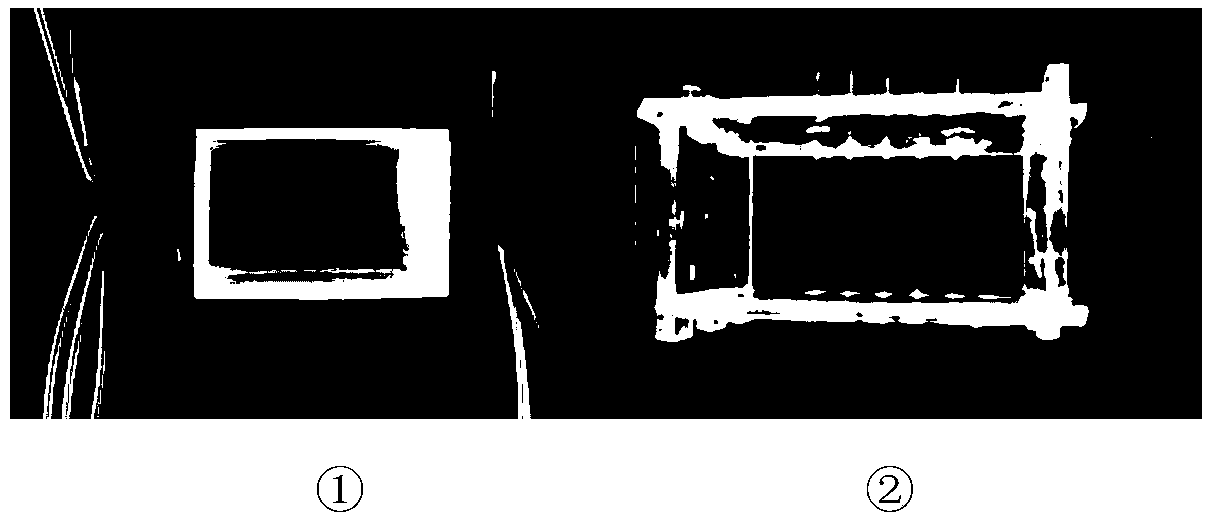

[0047] The in vitro artificial blood vessels are inserted into the corresponding apertures in the mold of Example 1 in sequence, similar to figure 2 ②, then use a micrometer to measure its thickness, and then use a universal tensile tester (Instron-3343) to detect its mechanical properties and calculate the elastic modulus.

Embodiment 3

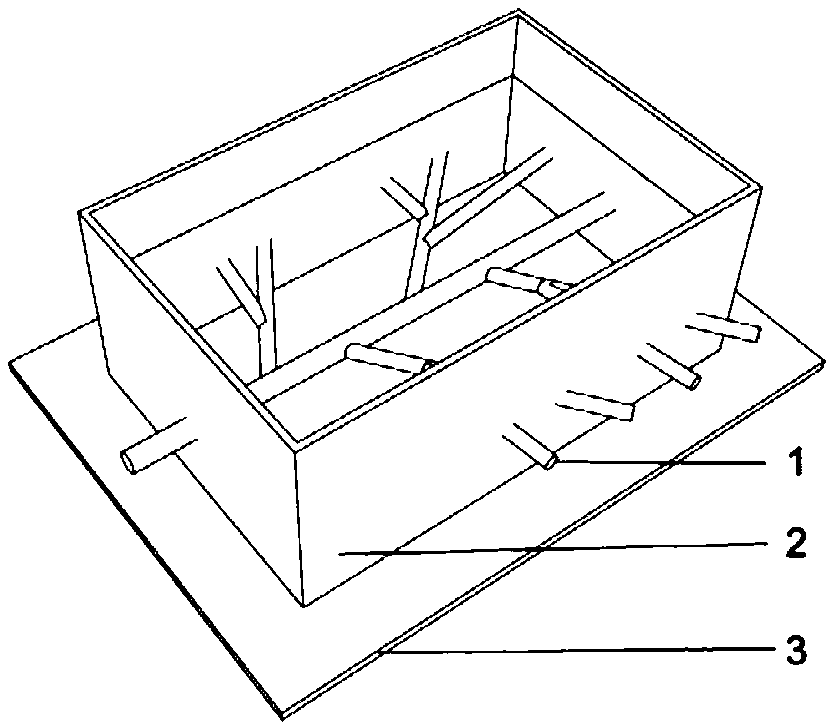

[0049] The mold of Example 1 is applied to the preparation of a hydrogel chip, specifically including:

[0050] 1) Select the mold prepared in Example 1 that meets the following requirements: the aperture diameter is 400 μm, and the two long sides of the mold are symmetrically provided with 8 through holes, and one end of the two short sides is provided with 1 through hole, and one end is provided with There are 2 two through holes (the above through holes are all located on the same level), with glass as the bottom surface.

[0051] 2) Prepare an aqueous gelatin solution with a mass volume ratio of 12.5%, add transglutaminase (TG enzyme) with a mass volume ratio of 10%, mix the gelatin solution and TG enzyme at room temperature, and then pour the gelatin solution for the first time. Stop pouring when the surface is flush with the lower edge of the through hole, place the glass capillary in the mold, assemble the required dendritic channel structure, and check the relative pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com