Pt/Rh nano composite material and preparation method and application thereof

A nanocomposite material and nanotechnology, applied in the field of nanomaterials, can solve the problems of unsuitable Pt-based nanomaterials, etc., and achieve the effects of excellent activity, simple preparation method, and enhanced activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The present embodiment prepares Pt / Rh nanocomposite material according to the following method:

[0059] Dissolve chloroplatinic acid and rhodium acetylacetonate in benzyl alcohol, add polyvinylpyrrolidone and formaldehyde, stir well, wherein the concentration of chloroplatinic acid is 0.7mmol / L, the concentration of rhodium acetylacetonate is 3.2mmol / L, and the concentration of polyvinylpyrrolidone is 16.0g / L, formaldehyde concentration is 7000mmol / L. The reaction was heated at 180°C for 8h. After the reaction is finished, cool down to room temperature, wash the reactant with acetone and ethanol, centrifuge to remove the supernatant, and obtain the Pt / Rh nanocomposite material.

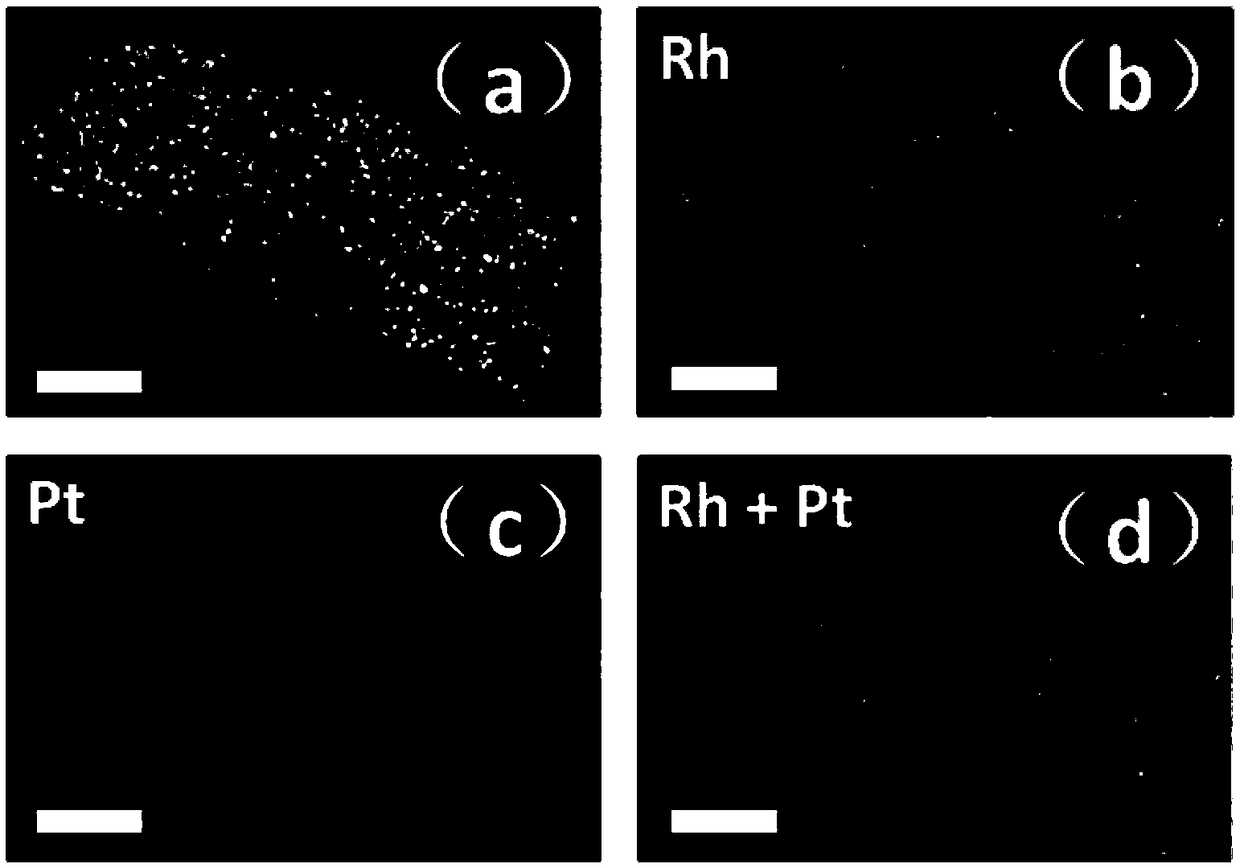

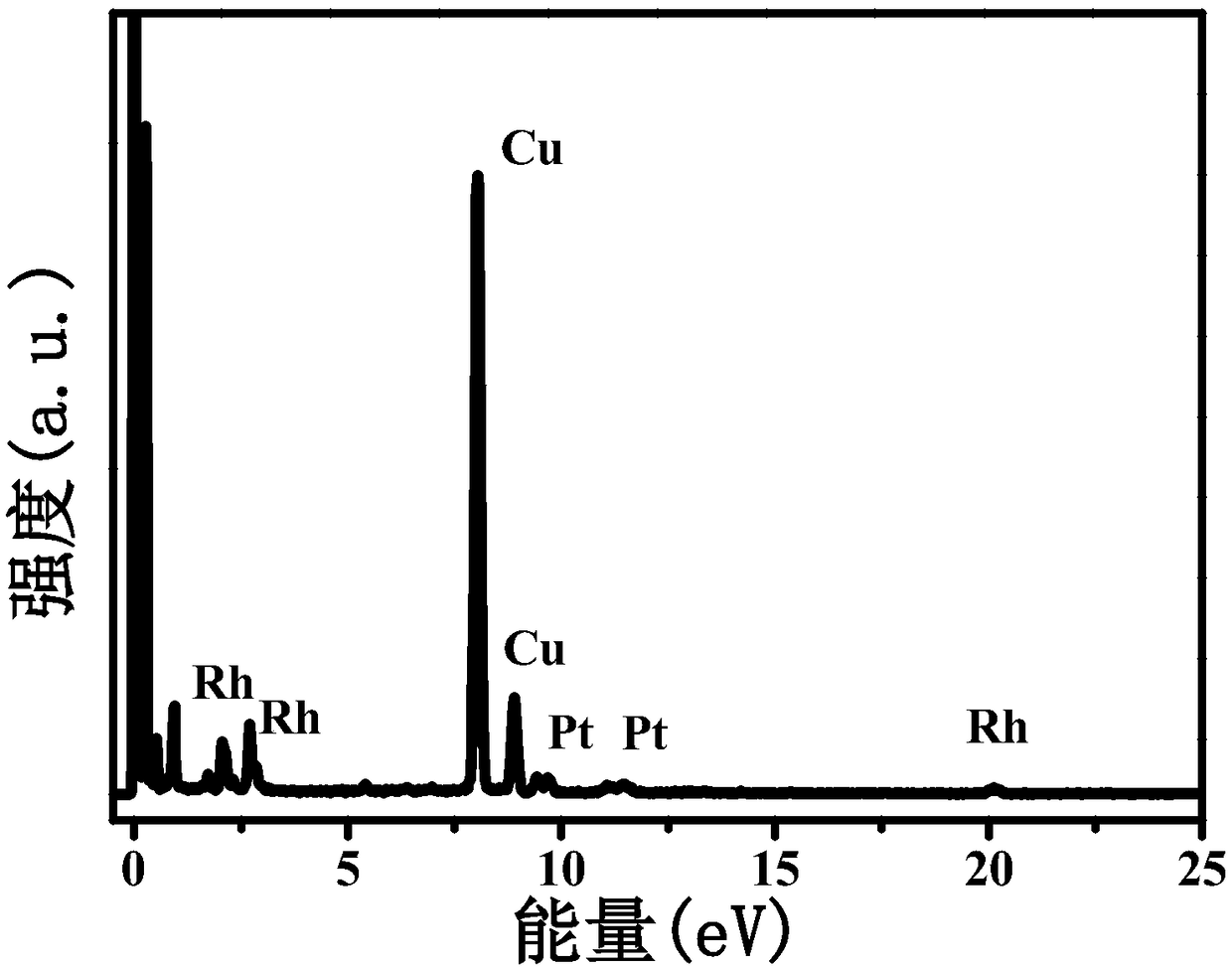

[0060] The Pt / Rh nanocomposite material provided by this embodiment is composed of Rh nanosheets and Pt nanoclusters loaded on the Rh nanosheets, the molar ratio of Pt nanoclusters to Rh nanosheets is 0.219:1, and the ratio of Rh nanosheets is The shape is trapezoidal, the average length of ...

Embodiment 2

[0071] The present embodiment prepares Pt / Rh nanocomposite material according to the following method:

[0072] Dissolve potassium chloroplatinate and rhodium chloride in ethylene glycol, add polyethylene glycol and formaldehyde, stir well, wherein the concentration of potassium chloroplatinate is 1.0mmol / L, the concentration of rhodium chloride is 3.0mmol / L, polyethylene glycol The diol concentration is 12.0g / L, and the formaldehyde concentration is 5000mmol / L. The reaction was heated at 180°C for 8h. After the reaction is finished, cool down to room temperature, wash the reactant with acetone and ethanol, centrifuge to remove the supernatant, and obtain the Pt / Rh nanocomposite material.

[0073] The Pt / Rh nanocomposite material provided in this embodiment is composed of Rh nanosheets and Pt nanoclusters loaded on the Rh nanosheets, the molar ratio of Pt nanoclusters to Rh nanosheets is 0.327:1, and the ratio of Rh nanosheets is The shape is trapezoidal, the average length ...

Embodiment 3

[0076] The present embodiment prepares Pt / Rh nanocomposite material according to the following method:

[0077] Dissolve platinum acetylacetonate and rhodium acetylacetonate in benzyl alcohol, add polyvinylpyrrolidone and salicylaldehyde, stir evenly, wherein the concentration of platinum acetylacetonate is 1.5mmol / L, the concentration of rhodium acetylacetonate is 3.3mmol / L, polyvinylpyrrolidone The concentration is 25.0g / L, and the concentration of salicylaldehyde is 4mmol / L. The reaction was heated at 180°C for 8h. After the reaction is finished, cool down to room temperature, wash the reactant with acetone and ethanol, centrifuge to remove the supernatant, and obtain the Pt / Rh nanocomposite material.

[0078] The Pt / Rh nanocomposite material provided in this embodiment is composed of Rh nanosheets and Pt nanoclusters loaded on the Rh nanosheets, the molar ratio of Pt nanoclusters to Rh nanosheets is 0.449:1, and the Rh nanosheets The shape is trapezoidal, the average len...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com