A kind of amidation modified graphene oxide and preparation method and application thereof

A technology of oxidized stone and amidation, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of high equipment and process operation requirements, harsh reaction conditions, etc., to improve physical barrier ability, simple and convenient operation , the effect of good dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

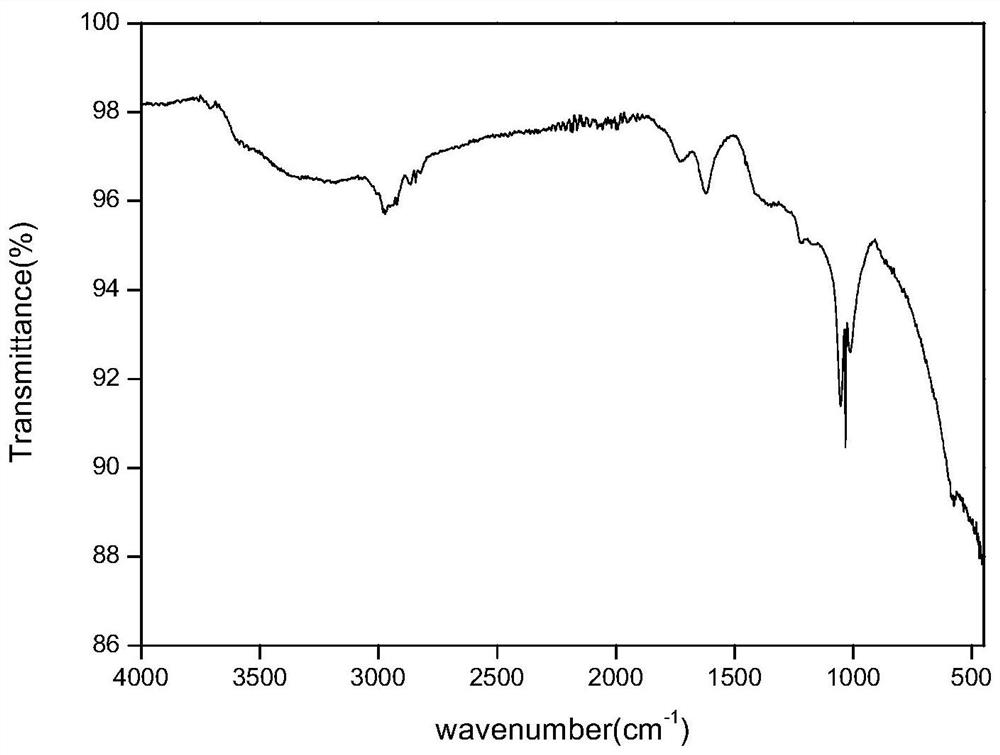

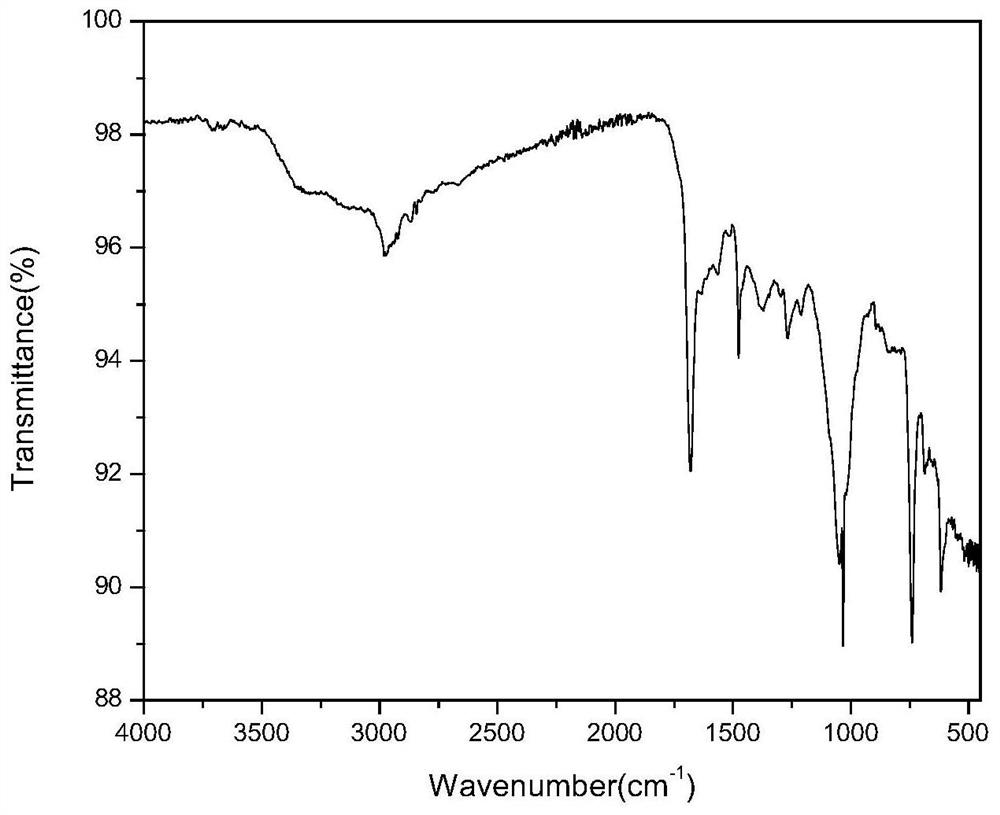

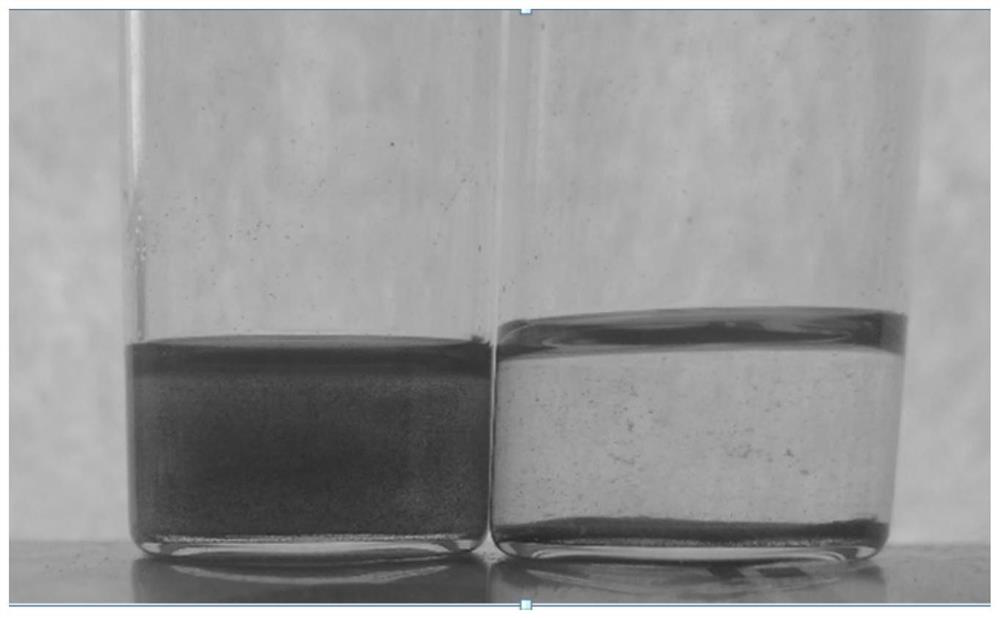

[0029] A kind of amidation modified graphene oxide (fGO), adopts following technical scheme to prepare:

[0030] Dissolve graphene oxide in ethanol, the concentration of graphene oxide in ethanol is 1mg / mL; 100W power ultrasonic treatment for 1 hour to fully disperse graphene oxide, and then transfer it to a round bottom flask. Weigh 2-aminobenzimidazole, slowly add it to the graphene oxide suspension, the optimal mass ratio of graphene oxide to 2-aminobenzimidazole is 1:10; magnetically stir at 65°C and heat for 48 hours to obtain Uniformly dispersed black suspension; cooled to room temperature, suction filtered, and repeatedly washed with ethanol; the obtained filter cake was placed in a vacuum drying oven, and vacuum-dried at 50°C for 24 hours to obtain amidated modified graphene oxide.

Embodiment 2

[0032] A kind of amidation modified graphene oxide (fGO), adopts following technical scheme to prepare:

[0033] Dissolve graphene oxide in DMF, the concentration of graphene oxide in DMF is 2mg / mL; 120W power ultrasonic treatment for 1 hour to fully disperse graphene oxide, and then transfer it to a round bottom flask. Weigh 2-aminobenzimidazole, slowly add it into the graphene oxide suspension, the optimal mass ratio of graphene oxide to 2-aminobenzimidazole is 1:8; magnetically stir at 70°C for 38 hours and heat to react to obtain Uniformly dispersed black suspension; cooled to room temperature, suction filtered, and repeatedly washed with ethanol; the obtained filter cake was placed in a vacuum drying oven, and vacuum-dried at 45°C for 24 hours to obtain amidated modified graphene oxide.

Embodiment 3

[0035] A kind of amidation modified graphene oxide (fGO), adopts following technical scheme to prepare:

[0036] Dissolve graphene oxide in ethanol, the concentration of graphene oxide in ethanol is 0.5mg / mL; 100W power ultrasonic treatment for 1 hour to fully disperse graphene oxide, and then transfer it to a round bottom flask. Weigh 2-aminobenzimidazole, slowly add it into the graphene oxide suspension, the optimal mass ratio of graphene oxide and 2-aminobenzimidazole is 1:12; magnetically stir at 60°C and heat for 40 hours to obtain Uniformly dispersed black suspension; cooled to room temperature, suction filtered, and repeatedly washed with ethanol; the obtained filter cake was placed in a vacuum drying oven, and vacuum-dried at 50°C for 24 hours to obtain amidated modified graphene oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com