Lanthanum-supported coating material and phosphorus-fixing material to control lake eutrophication, their preparation methods, phosphorus-fixing method and phosphorus-fixing grid plate

A coating material and eutrophication technology, applied in chemical instruments and methods, polluted waterways/lakes/ponds/rivers treatment, water pollutants, etc., can solve problems such as destroying the water body system and affecting the exchange of mud and water substances, Achieve the effects of simple preparation process, strong phosphorus binding ability and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

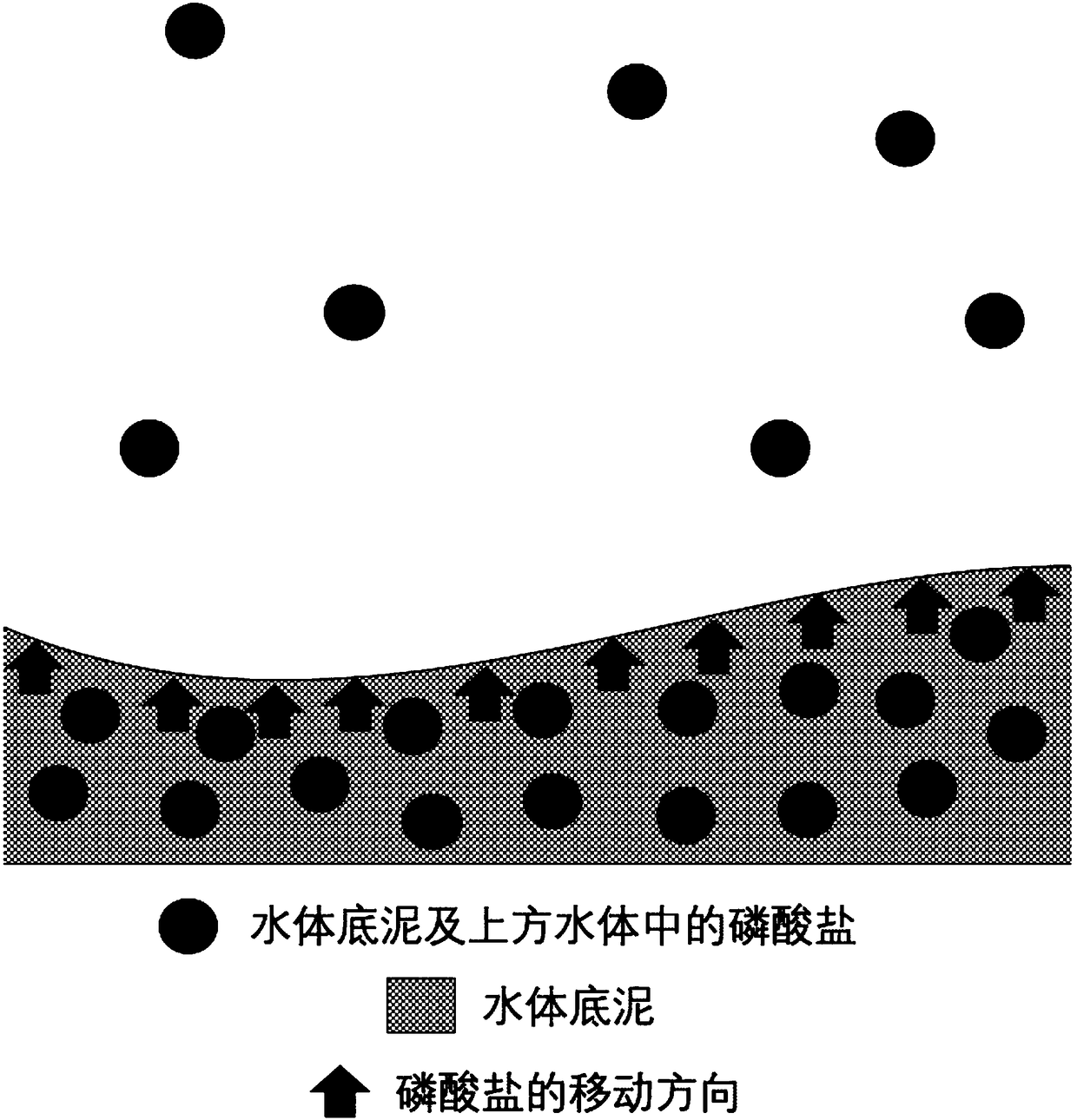

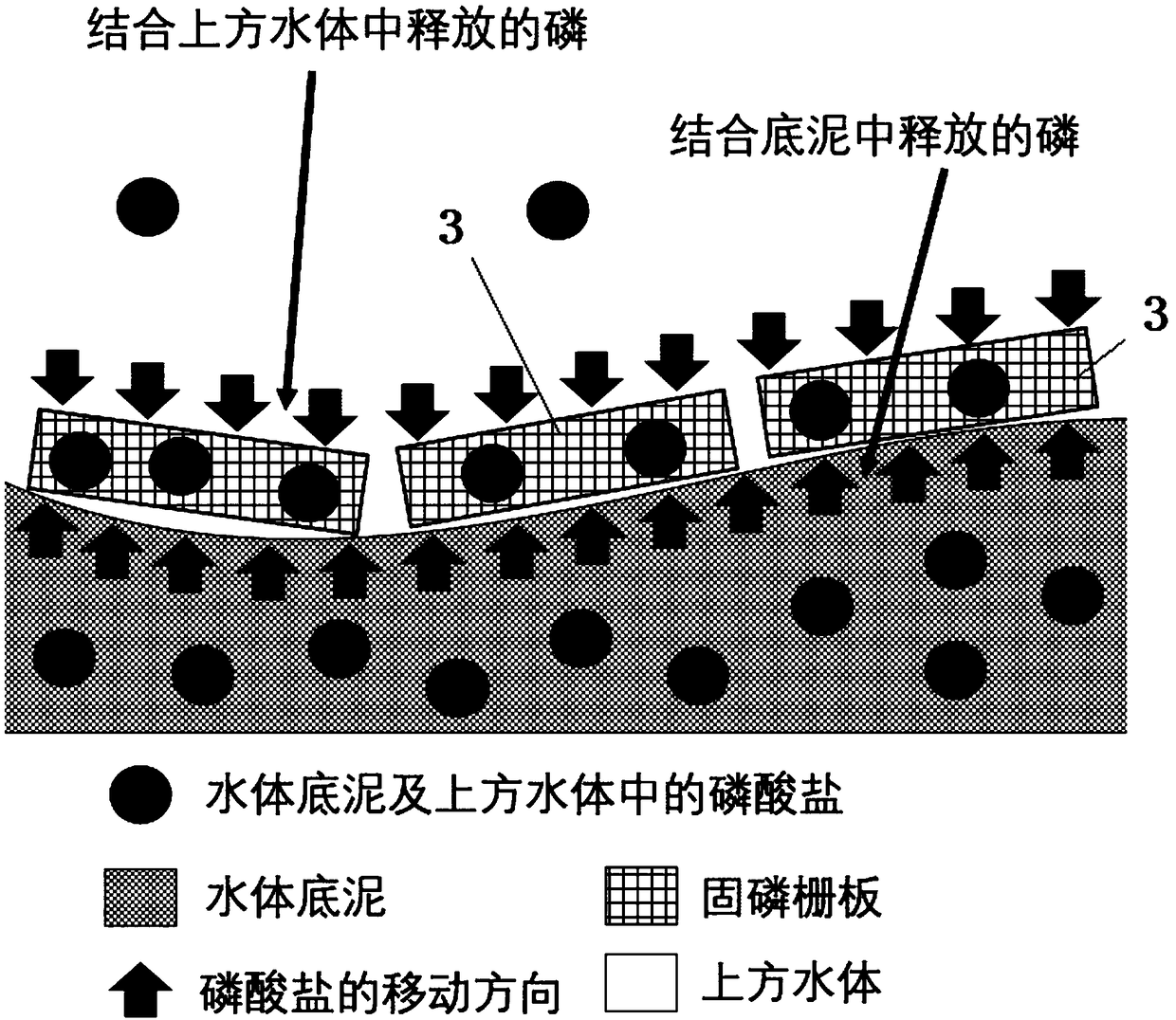

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention controls the preparation method of the lanthanum-loaded coating material of lake eutrophication, and the steps are as follows:

[0047] Step 1, adding 100-200ml of acetic acid with a mass percentage of 10-20% to every 1.50-2.50 grams of chitosan, until the chitosan is fully dissolved to obtain solution 1;

[0048] Step 2, add 0.05-0.15mol / L lanthanum nitrate solution to solution 1, and stir until fully dispersed to obtain solution 2, wherein the volume ratio of solution 1 to lanthanum nitrate solution is (1:7)-(1: 12);

[0049] Step 3, adding ammonia water with a mass percentage of 20-30% to the solution 2 to precipitate colloids in the solution 2 until the colloids are completely precipitated, and then separate the precipitated colloids, and the obtained colloids are lanthanum-loaded coating materials.

[0050] The present invention controls the preparation method of the phosphorus fixing material of lake eutrophication, comprises the following s...

Embodiment 1

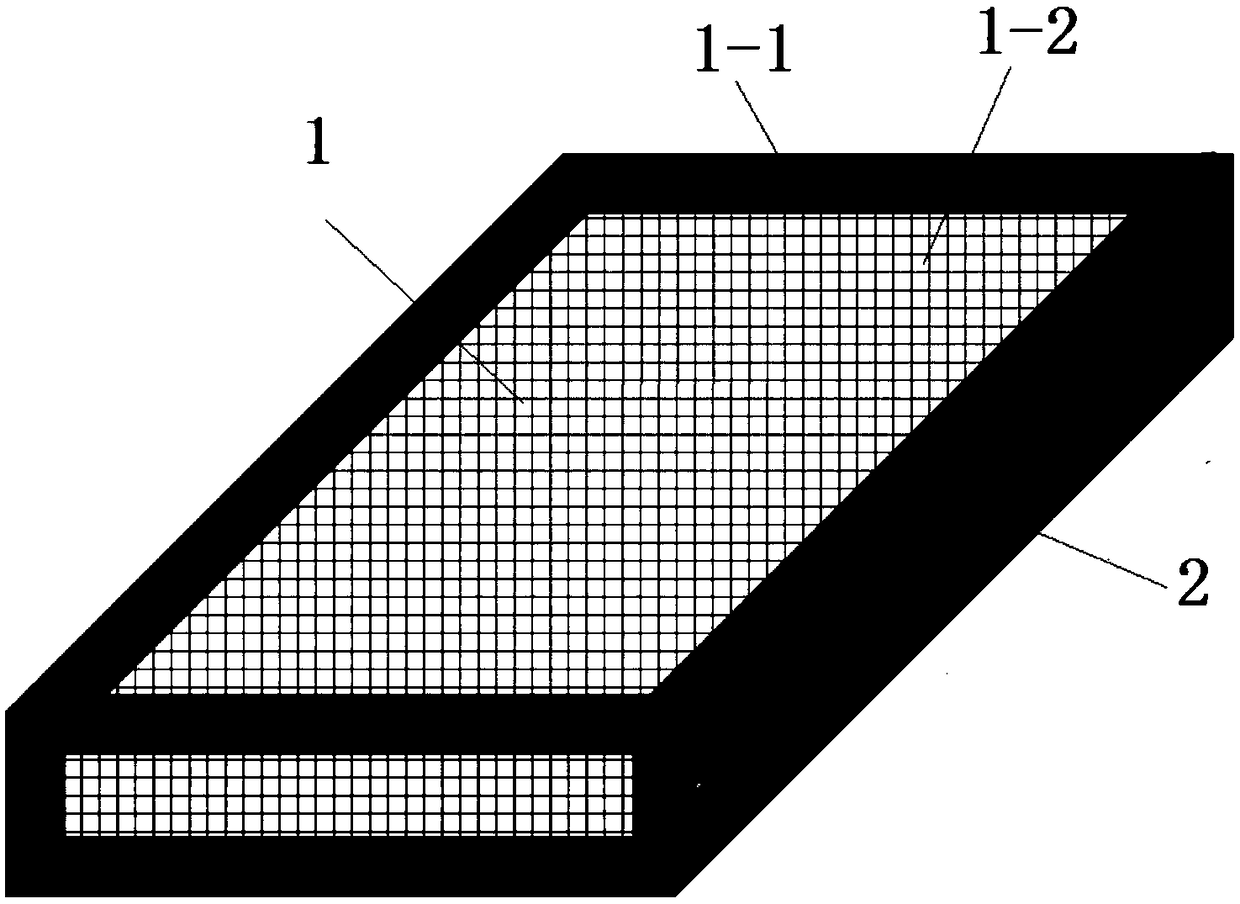

[0069] The preparation process of the phosphorus-fixing grid plate of the present embodiment is as follows:

[0070] Add 100ml of acetic acid with a mass percentage of 10% to every 1.50 grams of chitosan, and wait for the chitosan to fully dissolve to obtain solution 1; add 0.05mol / L lanthanum nitrate solution to solution 1, and stir until fully dispersed to obtain a solution 2. Among them, the volume ratio of solution 1 to lanthanum nitrate solution is 1:7; add ammonia water with a mass percentage of 20% to solution 2 to precipitate the lanthanum-loaded coating material generated in solution 2, and obtain The suspension with the lanthanum-loaded coating material is left to stand, the suspension is layered, the water in the upper layer is separated, and the lower colloid is obtained, which is the lanthanum-loaded coating material of the present invention. Add the activated carbon that has been ultrasonically washed into the lanthanum-loaded coating, take it out after stirring ...

Embodiment 2

[0073] The preparation process of the phosphorus-fixing grid plate of the present embodiment is as follows:

[0074] To every 2.50 grams of chitosan, add 200ml of acetic acid with a mass percentage of 20%, until the chitosan is fully dissolved to obtain solution 1; add 0.15mol / L lanthanum nitrate solution to solution 1, and stir until fully dispersed to obtain a solution 2. Among them, the volume ratio of solution 1 to lanthanum nitrate solution is 1:12; 30% by mass of ammonia water is added to solution 2 to precipitate the lanthanum-loaded coating material in solution 2, and the lanthanum-loaded coating material is obtained after complete precipitation. The suspension of the type coating material, and then the suspension is left to stand, the suspension is layered, the water in the upper layer is separated, and the lower colloid is obtained, which is the lanthanum-loaded coating material of the present invention. Add activated carbon that has undergone ultrasonic water washin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com