Method for treating chicken farm waste water by desulfovibrio microbial fuel cell

A desulfurizing vibrio and fuel cell technology is applied in the field of desulfurizing vibrio microbial fuel cell treatment of chicken farm wastewater, which can solve the problems of energy consumption, no chicken farm wastewater pollution, poor effect, etc., and achieves reduction of activity and solubility, elimination of Effects of heavy metal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

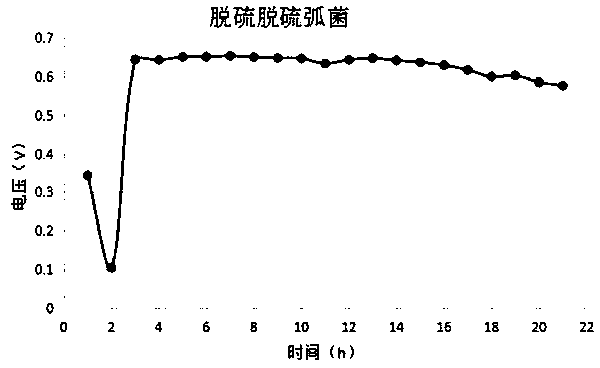

[0021] The method for treating chicken farm wastewater by the desulfovibrio microbial fuel cell in this embodiment includes the following steps:

[0022] Step 1: Strain preparation and activation: Activate the preserved Desulfovibrio and inoculate it into the culture solution. After airtight, culture it in a constant temperature incubator at a culture temperature of 25-35°C until the end of the logarithmic phase;

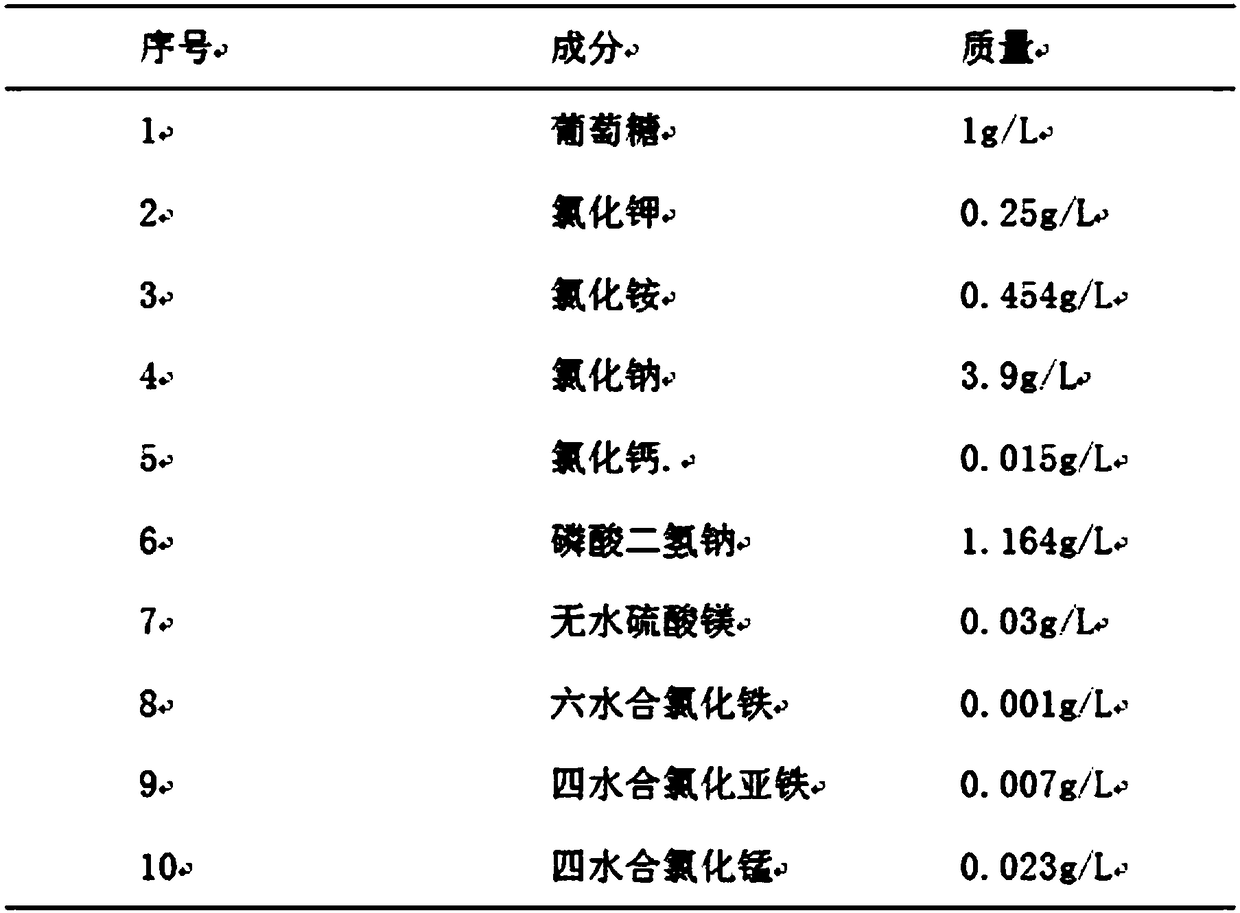

[0023] Step 2: Inoculation of bacteria in the anode chamber of the microbial fuel cell: mix the cultured bacteria liquid with the nutrient solution, buffer and sludge in a volume ratio of 1:2:1:5, and then inoculate the microbial fuel cell anode chamber to make The bacteria liquid is suspended in the anolyte or attached to the anode. The bacteria liquid is used to degrade the chicken farm wastewater and produce electrons and protons. The electrons reach the cathode through the external circuit and form a current loop with the protons that reach the cathode through the int...

Embodiment 2

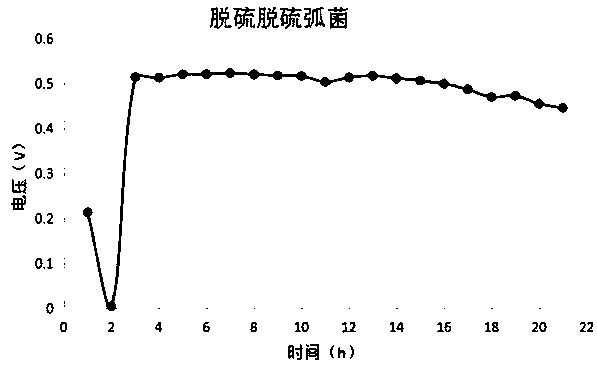

[0033] The method for treating chicken farm wastewater by the desulfovibrio microbial fuel cell in this embodiment includes the following steps:

[0034] Step 1: Strain preparation and activation: Activate the preserved Desulfovibrio and inoculate it into the culture solution. After airtight, culture in a constant temperature incubator until the end of the logarithmic phase;

[0035] Step 2: Inoculation of strains in the anode chamber of the microbial fuel cell: mix the cultured bacterial solution with nutrient solution, buffer and sludge in a volume ratio of 2:2:2:6, and then inoculate it into the anode chamber of the microbial fuel cell to make The bacteria liquid is suspended in the anolyte or attached to the anode. The bacteria liquid is used to degrade the chicken farm wastewater and produce electrons and protons. The electrons reach the cathode through the external circuit and form a current loop with the protons that reach the cathode through the intermediate diaphragm to gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com