Preparation process of round flat steel wire suitable for valve spring

A preparation process and valve spring technology are applied in the field of preparation technology of nearly round flat steel wire, which can solve the problems of undeveloped production and application, and achieve the convenience of subsequent processing and use, good steel wire straightness, fatigue resistance and bullet resistance. Excellent effect of reducing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

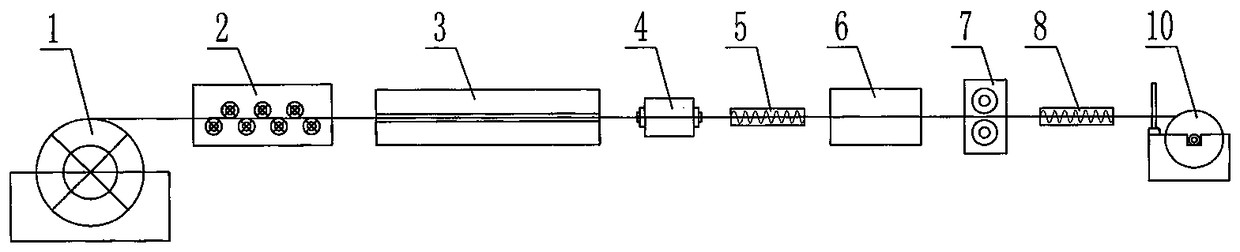

[0024] The preparation process of the present embodiment comprises the following steps:

[0025] A. Pickling and phosphating: In the pickling and phosphating tank 3, the raw material is SAE9254V and the diameter is φ6.5mm, and the wire rod is subjected to pickling and phosphating in the pickling and phosphating tank 3. The oxide skin on the surface of the wire rod is removed and a dense phosphating coating is obtained.

[0026] B. Round die drawing: the steel wire after pickling and phosphating passes through the inner cavity of the round die 4 for drawing to obtain a regular round steel wire with a diameter of Φ4.32mm.

[0027] C. Quenching and tempering: the drawn round steel wire moves forward at a linear speed of 10m / s, runs through the quenching furnace 5 longitudinally, heats the wire temperature to 900°C, and moves out of the quenching furnace 5 after holding for 10s, then runs through the quenching tank longitudinally 6. Rapidly cooled to 50°C by the 35°C oil quenchin...

Embodiment 2

[0033] The preparation process of the present embodiment comprises the following steps:

[0034] A. Pickling and phosphating: In the pickling and phosphating tank 3, pickling and phosphating the wire rod with a diameter of φ6.5mm and a raw material of 55CrSi after being unfolded by the pay-off device 1 and straightened by the straightening device 2 in sequence. The oxide skin on the surface of the wire rod is removed and a dense phosphating coating is obtained.

[0035] B. Round die drawing: the steel wire after pickling and phosphating passes through the inner cavity of the round die 4 for drawing to obtain a regular round steel wire with a diameter of Φ4.32mm.

[0036] C. Quenching and tempering: the drawn round steel wire moves forward at a linear speed of 10m / s, runs through the quenching heating furnace 5 longitudinally, heats the wire temperature to 920°C, moves out of the quenching heating furnace 5 after holding for 10s, and then runs longitudinally through the quenchi...

Embodiment 3

[0042] The preparation process of the present embodiment comprises the following steps:

[0043] A. Pickling and phosphating: In the pickling and phosphating tank 3, pickling and phosphating the wire rod with a raw material of 55CrSi and a diameter of φ8. The oxide skin on the surface of the wire rod is removed and a dense phosphating coating is obtained.

[0044]B. Round die drawing: The steel wire after pickling and phosphating passes through the inner cavity of the round die 4 for drawing to obtain a regular round steel wire with a diameter of Φ4.95mm.

[0045] C. Quenching and tempering: the drawn round steel wire moves forward at a linear speed of 20m / s, runs through the quenching furnace 5 longitudinally, heats the wire temperature to 910°C, moves out of the quenching furnace 5 after holding for 5s, and then runs through the quenching tank longitudinally 6. Rapidly cooled to 150°C by the 15°C oil quenching medium in the quenching tank 6; the quenched round steel wire ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com