Vertical magnetization mtj device and stt-mram

A vertical magnetization and device technology, applied in semiconductor devices, electric solid state devices, magnetic field controlled resistors, etc., can solve the problem of high critical write current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

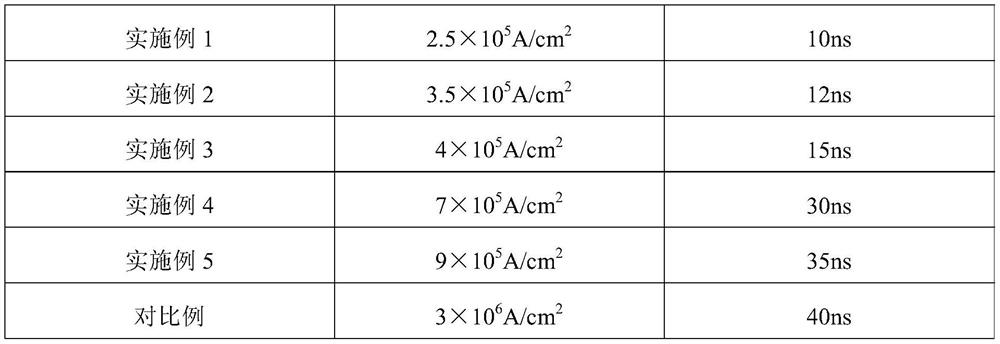

Embodiment 1

[0061] The STT-MRAM memory includes a plurality of MTJ devices, and also includes a switch circuit electrically connected to the MTJ devices, and the switch circuit includes a switch, a word line, a bit line and a source line. The specific connection relationship is the same as that in the prior art, and will not be repeated here.

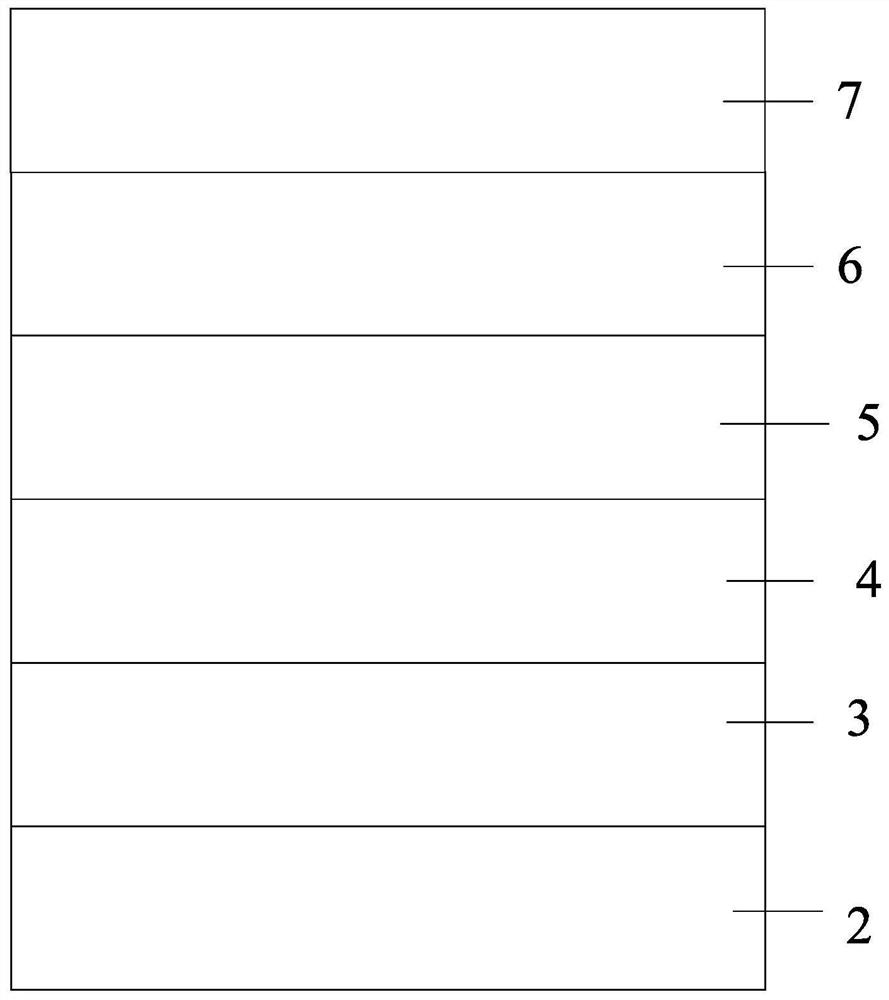

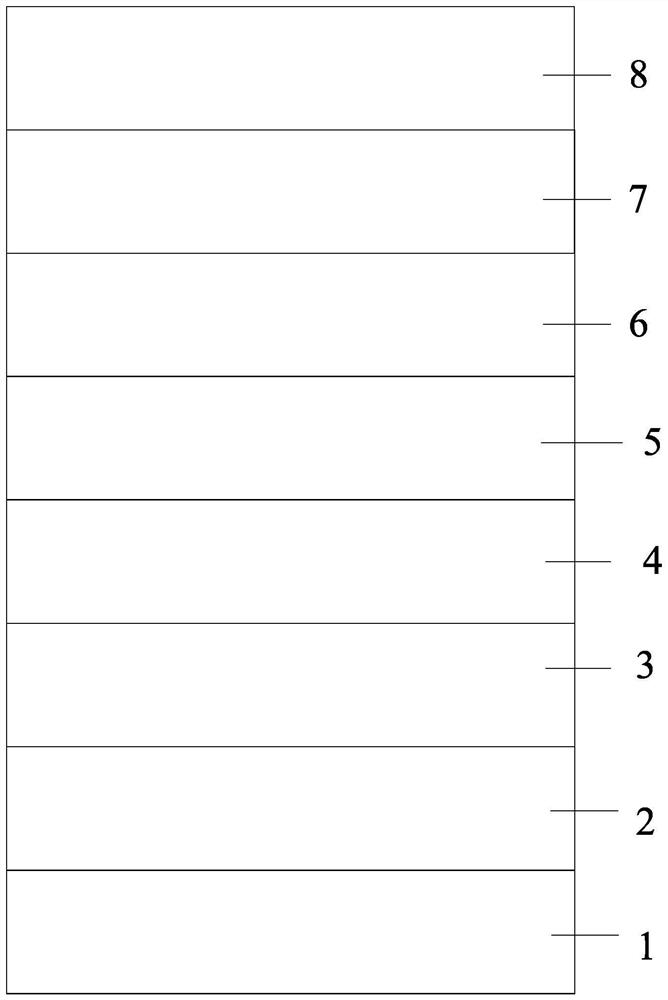

[0062] The structure of the MTJ unit is as figure 2 As shown, the first electrode layer 1 is a Ta layer with a thickness of The reference layer 2 includes a plurality of structural layers, along the direction away from the first electrode layer. Wherein the reference structure layer is CoFeB, and its magnetization direction is perpendicular to the film plane (i.e. the thickness direction of each layer); the insulating barrier layer 3 is a MgO layer, and its thickness is Its forbidden band width η 1 =7.6eV; the free layer 4 is Thick CoFeB layer; enhancement layer 5 is Pd layer, its thickness is The decoupling layer 6 is a Cu layer, and it...

Embodiment 2

[0064] The difference from Example 1 is that the thickness of the reinforcement layer is The thickness of the decoupling layer is

Embodiment 3

[0066] The difference from Example 1 is that the thickness of the reinforcement layer is The thickness of the decoupling layer is

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com