A surface dendrite-free high-safety metal lithium anode and preparation method and application thereof

A metal lithium and negative electrode technology, applied in the field of high-safety metal lithium negative electrode and its preparation, to achieve the effects of reducing irreversible consumption, high cycle Coulomb efficiency, and reducing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

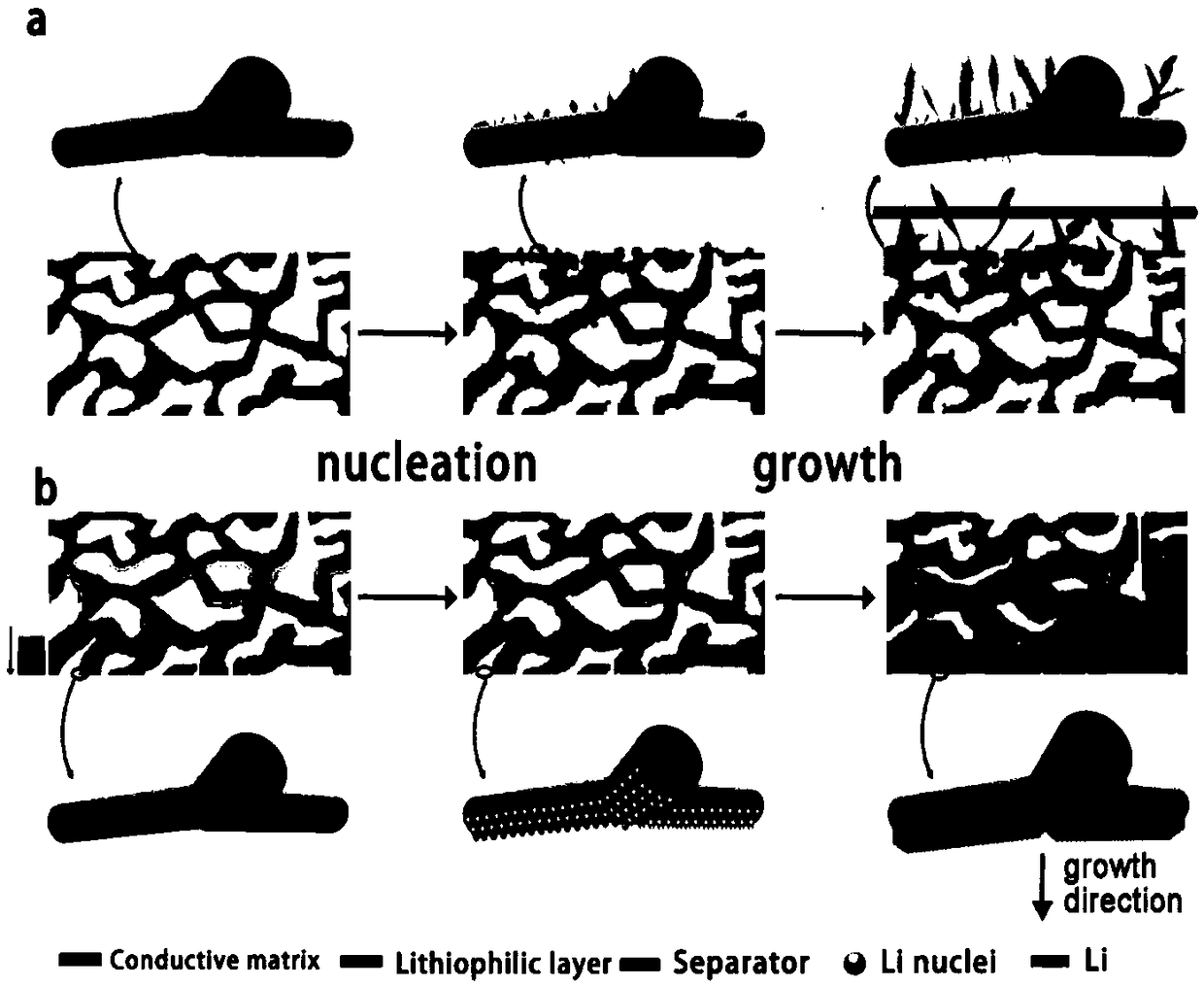

[0046] In yet another specific embodiment of the present invention, a method for preparing the above-mentioned metallic lithium negative electrode is provided, the method comprising:

[0047] S1. Sputtering a lithium-friendly material on a three-dimensional porous substrate;

[0048] S2. Use the material prepared in step S1 and metal lithium as a counter electrode, and use the electrochemical deposition method to deposit metal lithium into the material prepared in step S1 to obtain a metal lithium negative electrode; or pour molten metal lithium into the material prepared in step S1 to obtain a metal Lithium negative electrode.

[0049] In yet another specific embodiment of the present invention, in the step S1,

[0050] Sputtering the lithium-philic material on one side of the three-dimensional porous matrix by magnetron sputtering, so that the lithium-philic layer formed by the lithium-philic material is distributed on the side of the fiber of the three-dimensional porous m...

Embodiment 1

[0059] (1) Preparation of three-dimensional porous copper foam with spatially anisotropic distribution of lithiophilic layer

[0060] The commercialized copper foam was rolled with a 50% strain using a roller press, then ultrasonically cleaned in dilute hydrochloric acid, deionized water, and absolute ethanol in sequence, and then vacuum-dried (named CuF). Lithophilic Au layer was sputtered onto the side of CuF by magnetron sputtering method, and the Au layer was distributed on the side of the foam copper fiber facing the target, thus a three-dimensional porous copper foam with spatially anisotropic distribution of lithiophilic layer was obtained (named CuF@Au).

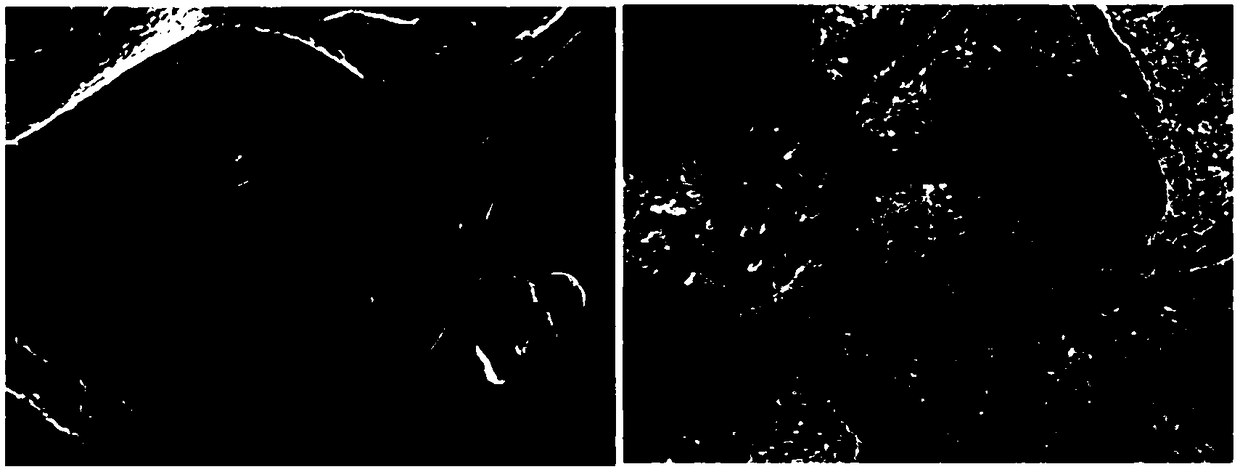

[0061] (2) Preparation of a high-safety metal lithium anode without dendrites on the surface

[0062] Cut the above-mentioned three-dimensional porous copper structure with Au layer distributed anisotropically into a certain shape, assemble a button battery with metal lithium as the counter electrode, and deposit 1m...

Embodiment 2

[0065] (1) Preparation of three-dimensional porous copper foam with spatially anisotropic distribution of lithiophilic layer

[0066] The commercialized copper foam was rolled with a 50% strain using a roller press, then ultrasonically cleaned in dilute hydrochloric acid, deionized water, and absolute ethanol in sequence, and then vacuum-dried (named CuF). Lithophilic Au layer was sputtered onto the side of CuF by magnetron sputtering method, and the Au layer was distributed on the side of the foam copper fiber facing the target, thus a three-dimensional porous copper foam with spatially anisotropic distribution of lithiophilic layer was obtained (named CuF@Au).

[0067] (2) Preparation of a high-safety metal lithium anode without dendrites on the surface

[0068] Cut the above-mentioned three-dimensional porous copper structure with Au layer distributed anisotropically into a certain shape, assemble a button battery with metal lithium as the counter electrode, and deposit 2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com