Flexible solid-state battery and preparation method thereof

A technology of solid-state batteries and solid-state electrolyte membranes, applied in the field of solar energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

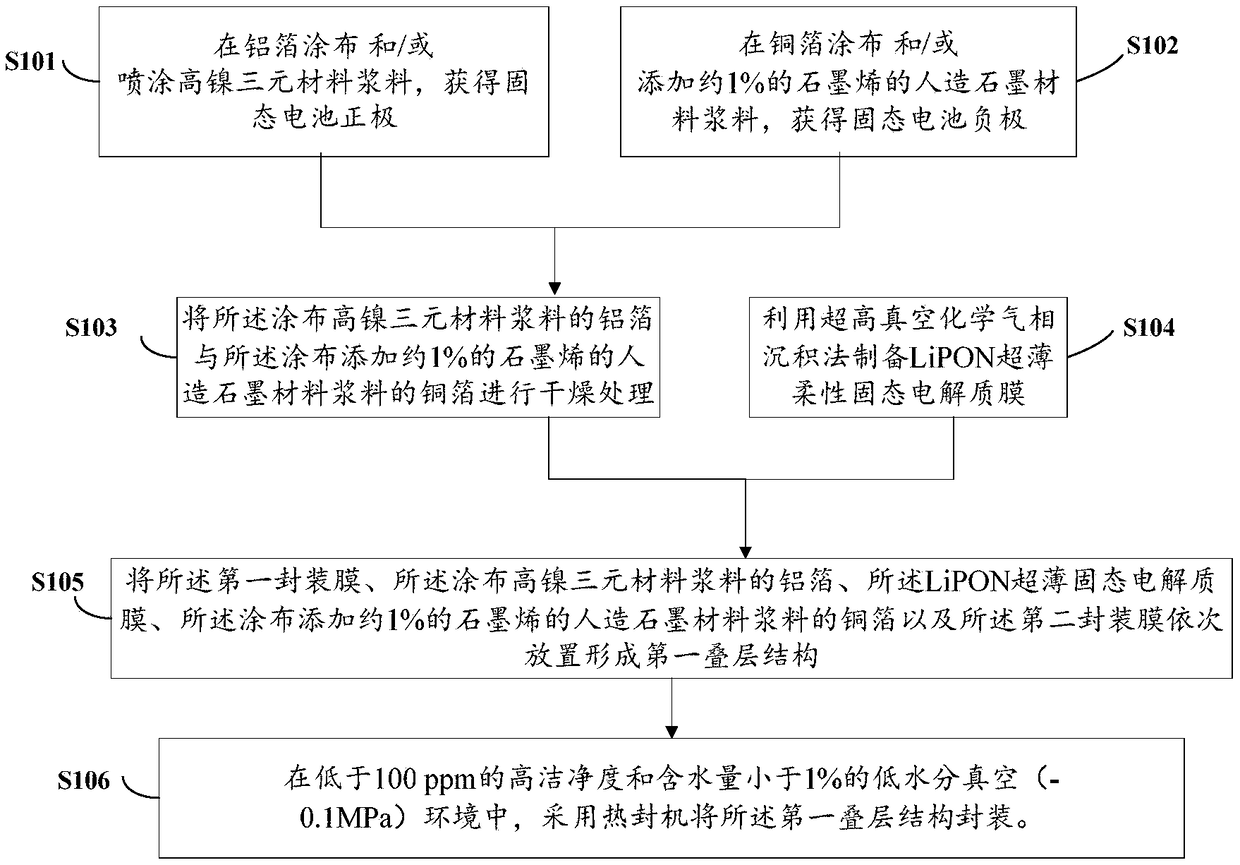

[0054] Such as figure 1 , which shows a flow chart of a method for preparing a 5-layer ultra-thin flexible solid-state battery provided in Embodiment 1 of the present application. This flowchart reflects the basic idea of the subsequent embodiments. The flowchart also reflects the preparation method of this ultra-thin flexible solid-state battery.

[0055] The preparation method of the ultra-thin flexible solid-state battery provided by the present application will be described and illustrated in detail below through specific examples.

[0056] Such as figure 1 As shown, the preparation method of the ultra-thin flexible solid-state battery is as follows:

[0057] Step S101, coating and / or spraying the positive electrode material on the positive electrode current collector to obtain a flexible solid-state battery positive electrode;

[0058]The positive electrode of the flexible solid-state battery includes a positive electrode current collector and a positive electrode m...

Embodiment 2

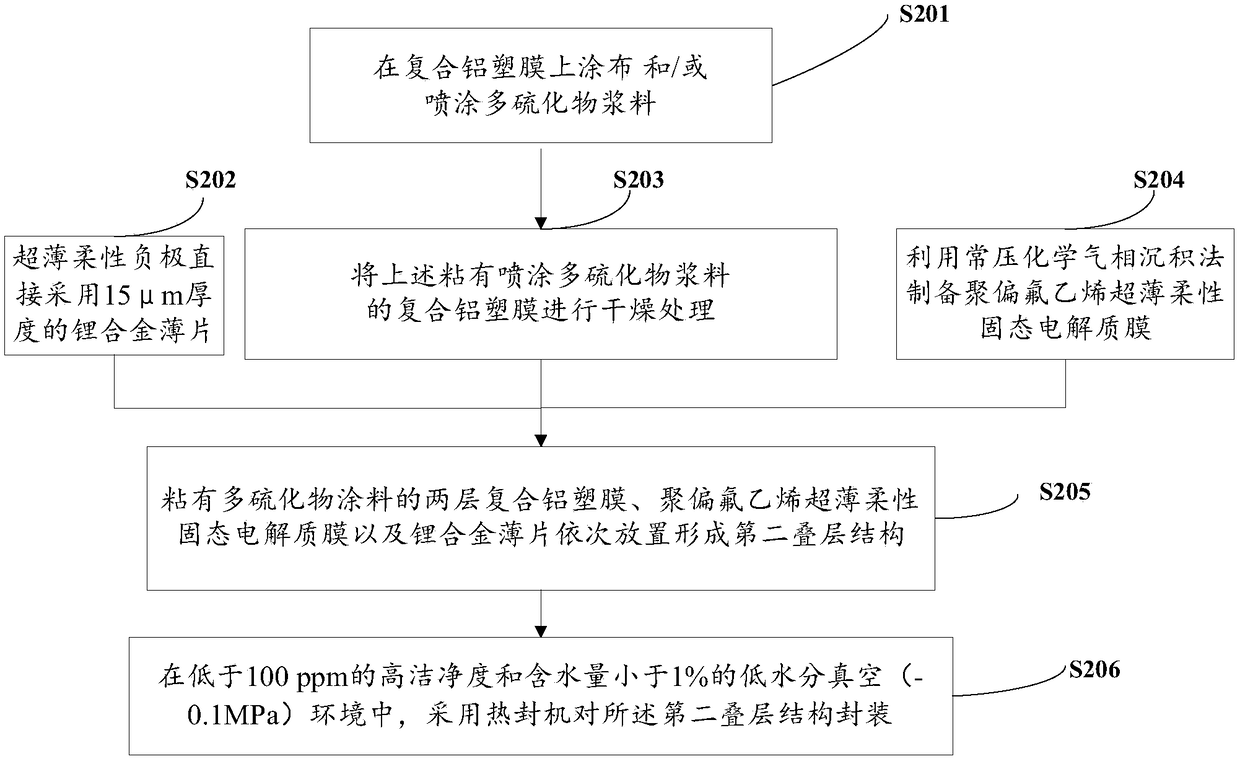

[0083] Such as figure 2 As shown, it shows the flow chart of another 3-layer ultra-thin flexible solid-state battery preparation method provided in Example 2 of the present application. This flowchart also reflects the basic idea of the subsequent embodiments. The flowchart also reflects the preparation method of this ultra-thin flexible solid-state battery.

[0084] The preparation method of another ultra-thin flexible solid-state battery provided by the present application is introduced and illustrated through specific examples below.

[0085] Such as figure 2 As shown, the preparation method of the additional ultra-thin flexible solid-state battery is as follows:

[0086] Step S201, coating and / or spraying the positive electrode material on the composite aluminum-plastic film;

[0087] In this embodiment, the positive electrode material is polysulfide material. In this step, the polysulfide, the conductive agent, and the binder are prepared in proportion to form a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com