Hawthorn powder preparation method

A technology of hawthorn powder and hawthorn, applied in the functions of food ingredients, food ingredients containing natural extracts, food drying, etc., can solve the problems of hawthorn powder nutrient destruction, unfavorable hawthorn powder nutritional value, complex preparation process, etc. The improvement of other indicators, the effect of the improvement of indicators such as good brewability and content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of hawthorn powder, comprising the following preparation steps:

[0022] Step 1. After the hawthorn raw material is checked and accepted, it is pretreated by removing impurities, crushing to 20 mesh, and putting it into a tank. Add distilled water with 10 times the mass of hawthorn to the pretreated hawthorn raw material, and heat it to 100°C for water extraction. Three times, 1.5 hours each time, filter, and combine three extracts.

[0023] Step 2: Concentrate the extract at a temperature of 70°C and a vacuum of 0.03MPa for 50 minutes to form an extract, and then spray dry it at a temperature of 70°C and a pressure of 30mm (300Pa) in a water column for 60 minutes. Spray-dry until the moisture content is less than 10%, crush to 80 mesh, pack, and sterilize at 105°C for 2 hours.

Embodiment 2

[0025] A preparation method of hawthorn powder, comprising the following preparation steps:

[0026] Step 1. After the hawthorn raw material is checked and accepted, it is pretreated by removing impurities, crushing to 25 mesh, and putting it into a tank. Add distilled water with 11 times the mass of hawthorn to the pretreated hawthorn raw material, and heat it to 90°C for water extraction. Three times, 1.8 hours each time, filter, and combine the three extracts.

[0027] Step 2: Concentrate the extract at a temperature of 65°C and a vacuum of 0.01MPa for 55 minutes to form an extract, and then spray dry it at a temperature of 65°C and a pressure of 40mm (400Pa) in a water column for 70 minutes. It is spray-dried until the moisture content is less than 10%, crushed to 100 mesh, packaged, and sterilized at 100°C for 2.5 hours to obtain the finished product.

Embodiment 3

[0029] A preparation method of hawthorn powder, comprising the following preparation steps:

[0030] Step 1. After the hawthorn raw material is checked and accepted, it is pretreated by removing impurities, crushing to 30 mesh, and putting it into a tank. Add distilled water with 12 times the mass of hawthorn to the pretreated hawthorn raw material, and heat it to 110°C for water extraction. Three times, 1.2 hours each time, filter, and combine the three extracts.

[0031] Step 2: Concentrate the extract for 45 minutes at a temperature of 75°C and a vacuum of 0.05MPa to form an extract, then spray dry it at a temperature of 75°C and a pressure of 20mm (200Pa) in a water column for 50 minutes, It is spray-dried until the moisture content is less than 10%, crushed to 90 mesh, packaged, and sterilized at 110°C for 1.5 hours to obtain the final product.

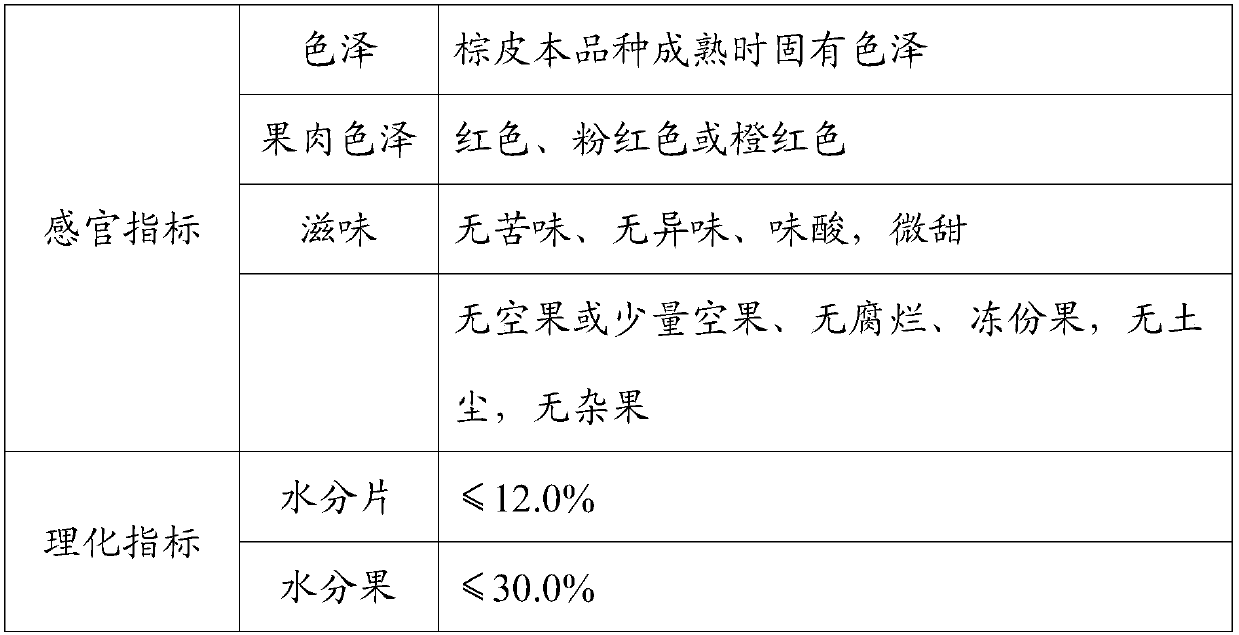

[0032] In the above examples, the acceptance criteria of hawthorn raw materials are as shown in Table 1:

[0033] Table 1 Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com