Limestone-gypsum method based oxidation control method for flue gas desulfurization slurry

A desulfurization slurry and control method technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of energy waste, control, and high sulfite content in desulfurization slurry, and achieve reduced manual operations, good quality, and systematic running stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

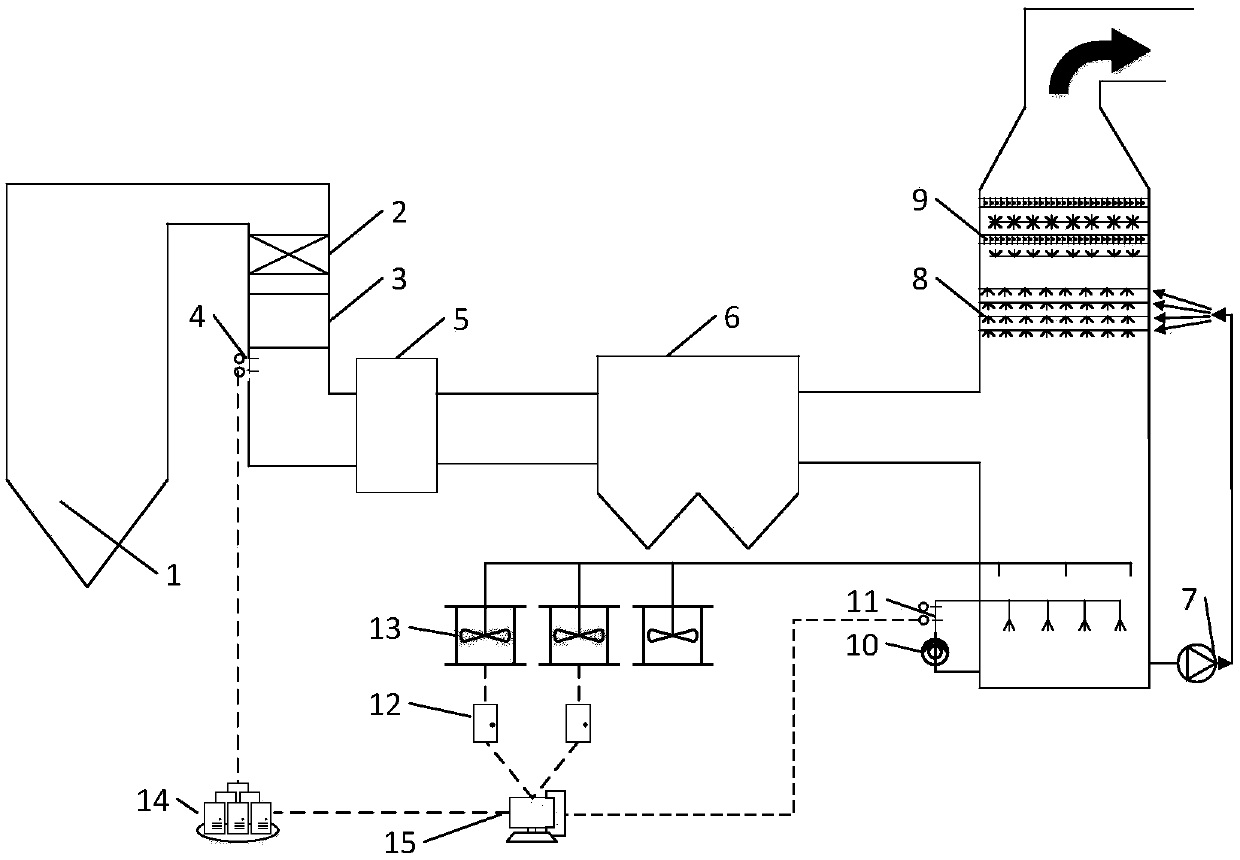

[0039] like figure 1 As shown, the limestone-gypsum flue gas desulfurization slurry oxidation control system includes a flue gas system, a desulfurization slurry system and an oxidation air system.

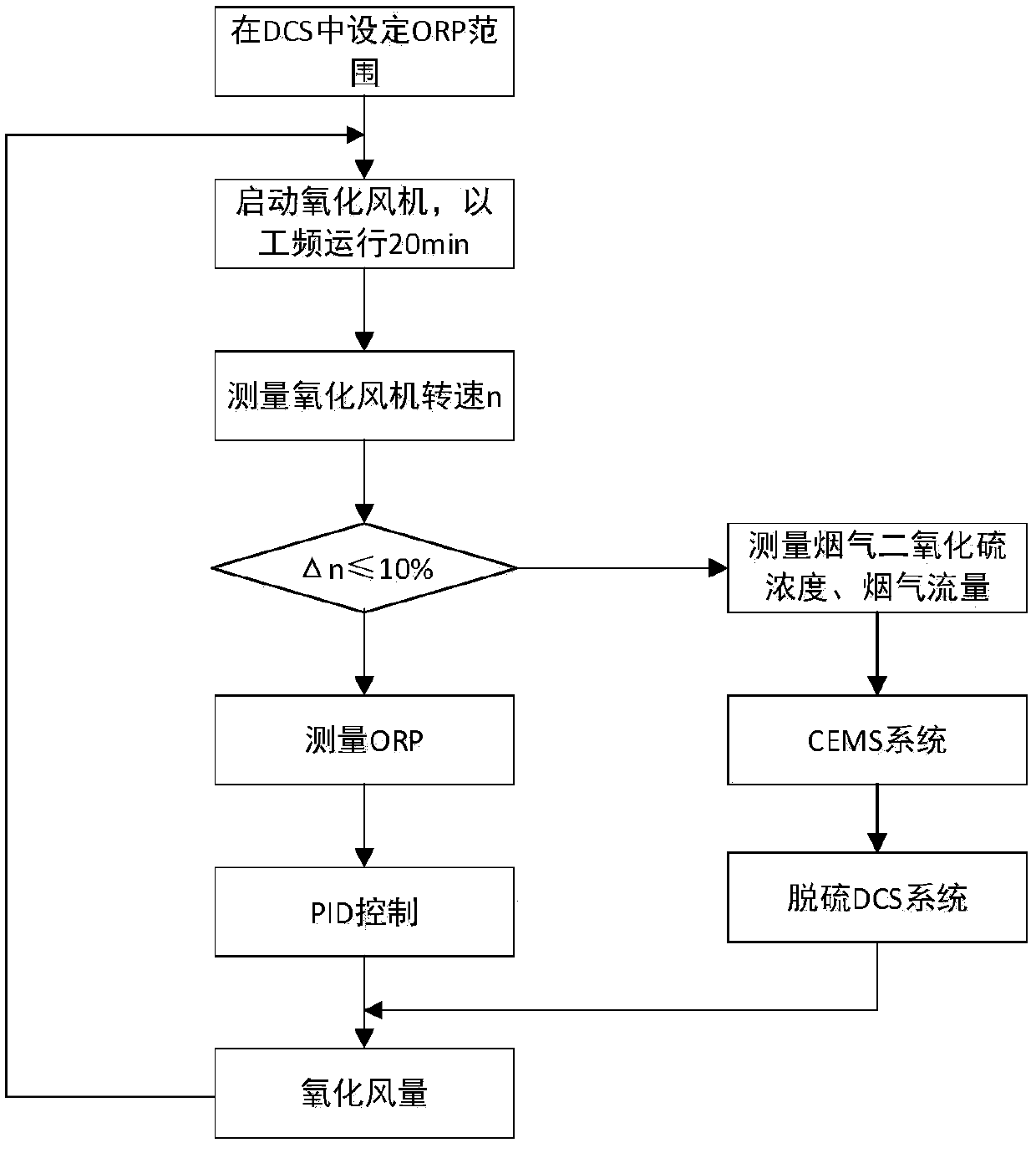

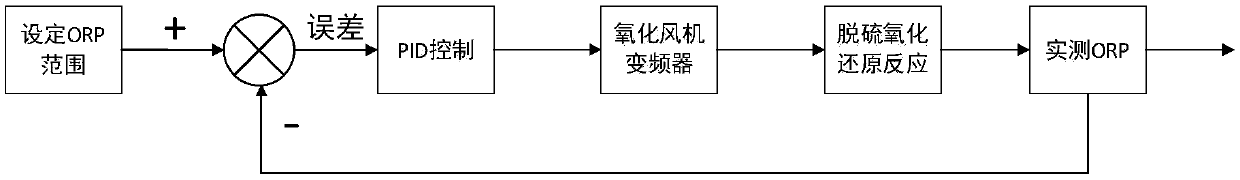

[0040] Flue gas system: After the flue gas produced by combustion comes out of the boiler 1, it first passes through the economizer 2, then passes through the SCR denitrification device 3, and then passes through the flue gas SO 2 Concentration sensor, flue gas flow sensor 4, the flue gas SO measured here 2 The concentration and flue gas flow rate will be uploaded to the CEMS system 14, and then processed in the desulfurization DCS system 15 to provide the control signal to the frequency converter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com