Solid-liquid reaction device with grinding function

A solid-liquid reaction and functional technology, applied in chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical processes, chemical instruments and methods, etc., can solve the problem of low reaction efficiency and reduced diffusion speed of solid raw materials , reduce reaction efficiency and other issues, to achieve the effect of improving reaction efficiency, avoiding material sticking, and improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

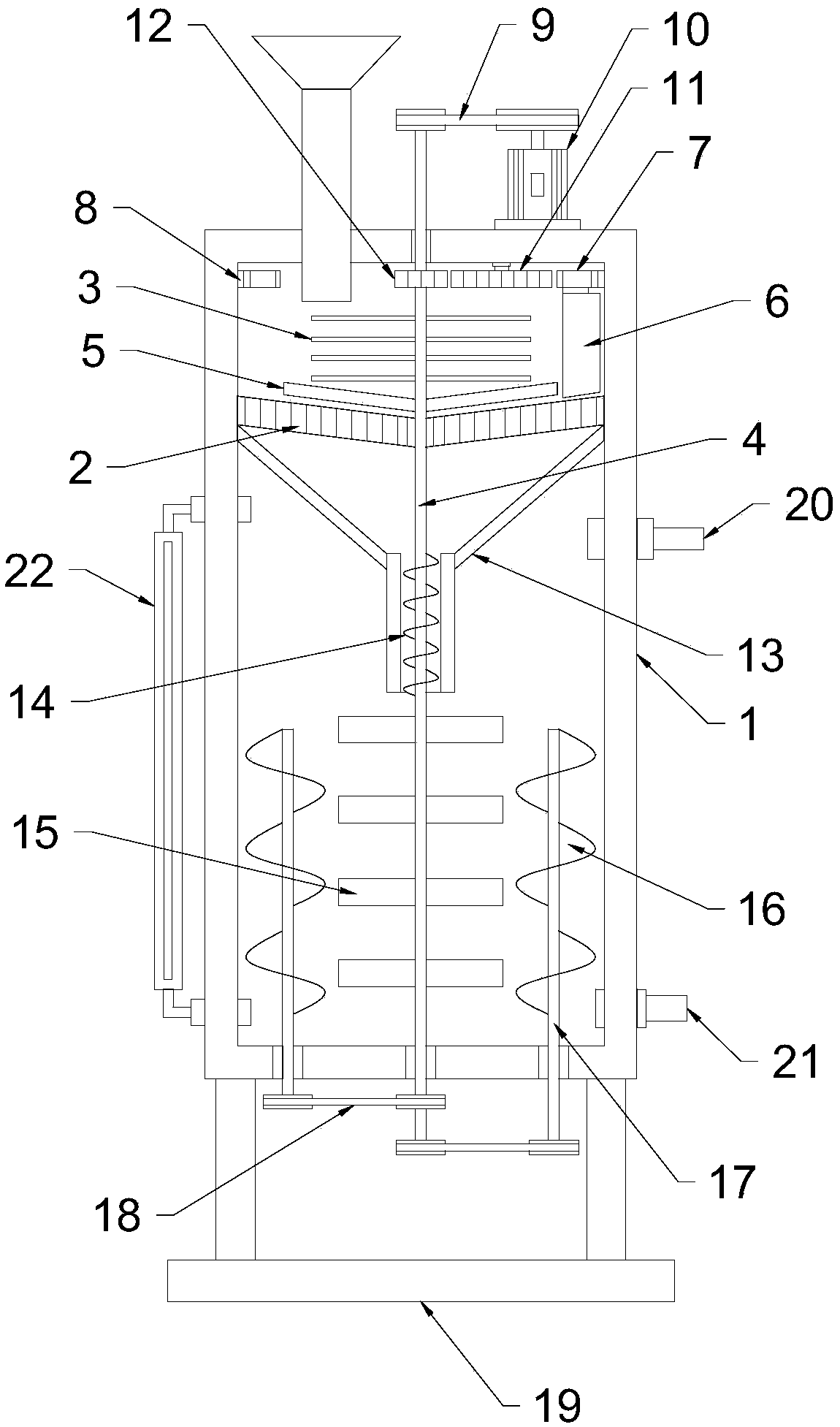

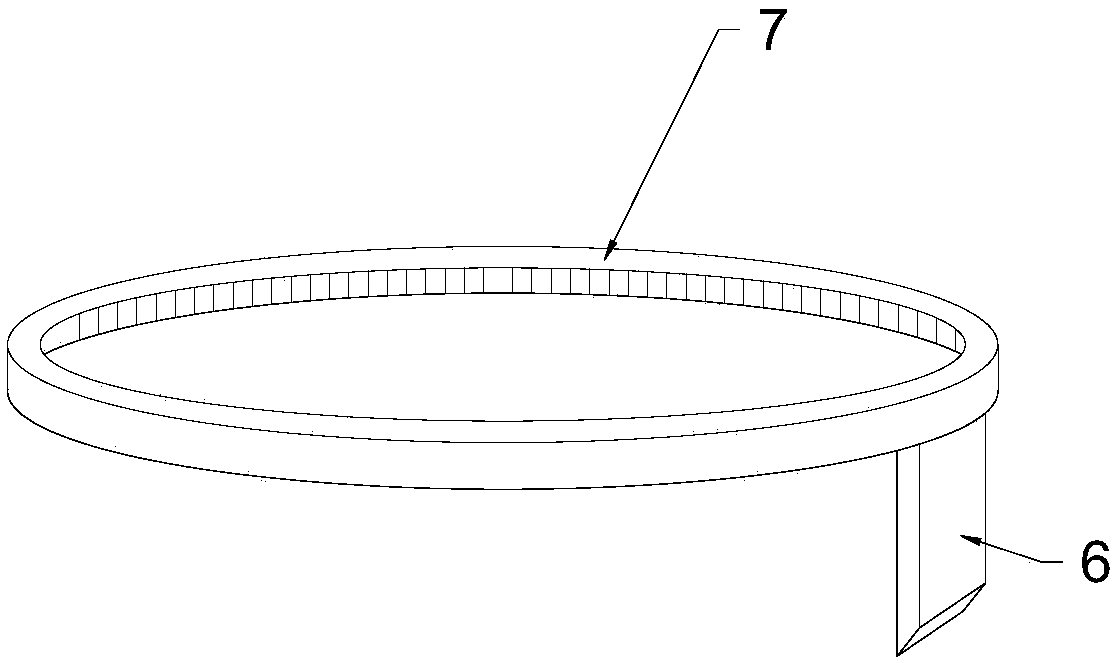

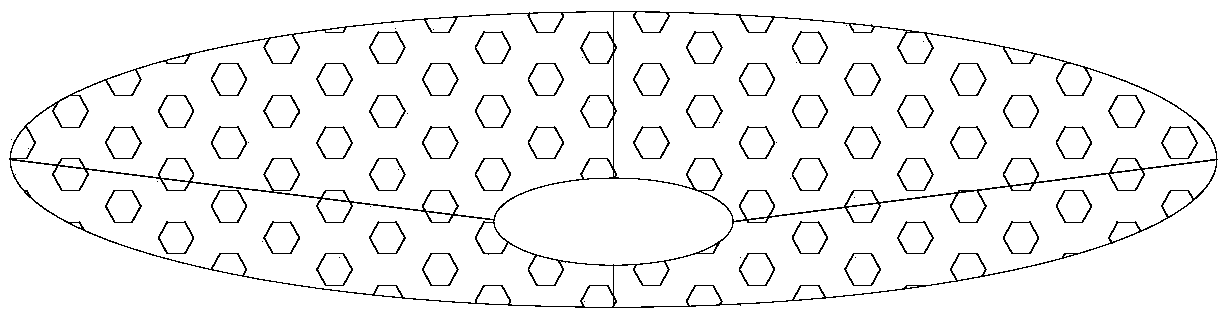

[0022] see Figure 1~3 , in an embodiment of the present invention, a solid-liquid reaction device with crushing function includes a tank body 1, a drive motor 10, a stirring plate 15 and a liquid level gauge 22; the upper end of the tank body 1 is connected with a feeding hopper, and the solid raw material is Feeding hopper input; the tank body 1 is provided with a screening cover 2, the screening cover 3 is an inverted conical structure and evenly distributed with sieve holes, the screening cover 3 is fixedly connected with the inner wall of the tank body 1, and a crushing knife is arranged above the screening cover 3 3. The crushing knife 3 is fixedly connected with the rotating shaft 4, the upper end of the rotating shaft 4 extends above the tank body 1 and is rotatably connected with the tank body 1 through a bearing sleeve, and the rotating shaft 4 is connected with the output shaft of the driving motor 10 through the first transmission belt 9 , the drive motor 10 is fix...

Embodiment 2

[0027] see Figure 4 The difference between this embodiment and Embodiment 1 is that a heating device 23 is embedded in the tank body 1, the heating device 23 is a resistance wire, the heating device 23 is connected with a temperature control switch 24, and a thermometer is arranged on the right side of the tank body 1 25. It is convenient to control the temperature of raw materials in tank 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com