Equipment for recovery processing of solid waste into home crafts

A technology for solid waste and handicrafts, applied in auxiliary molding equipment, applications, manufacturing tools, etc., can solve the problems of uncertain drying time, reduced utilization rate of masonry, low economic benefits, etc., to improve bonding effect and utilization efficiency , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

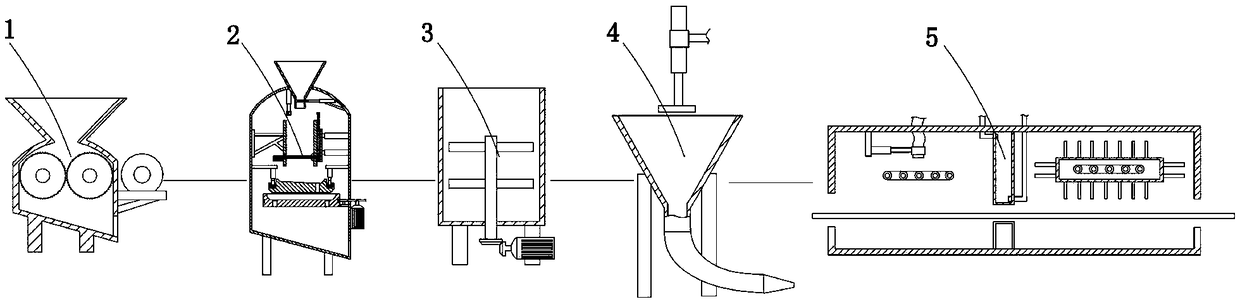

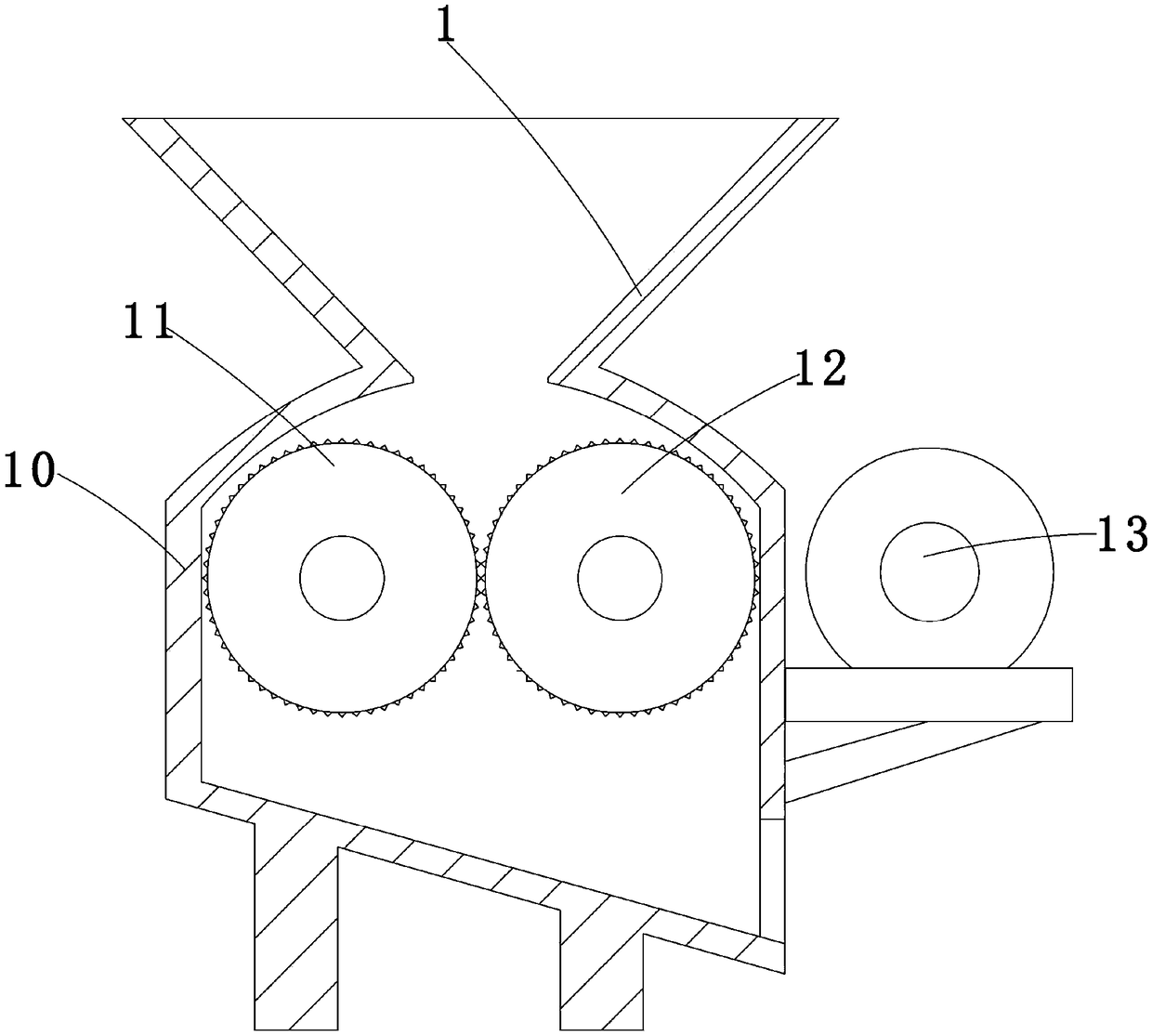

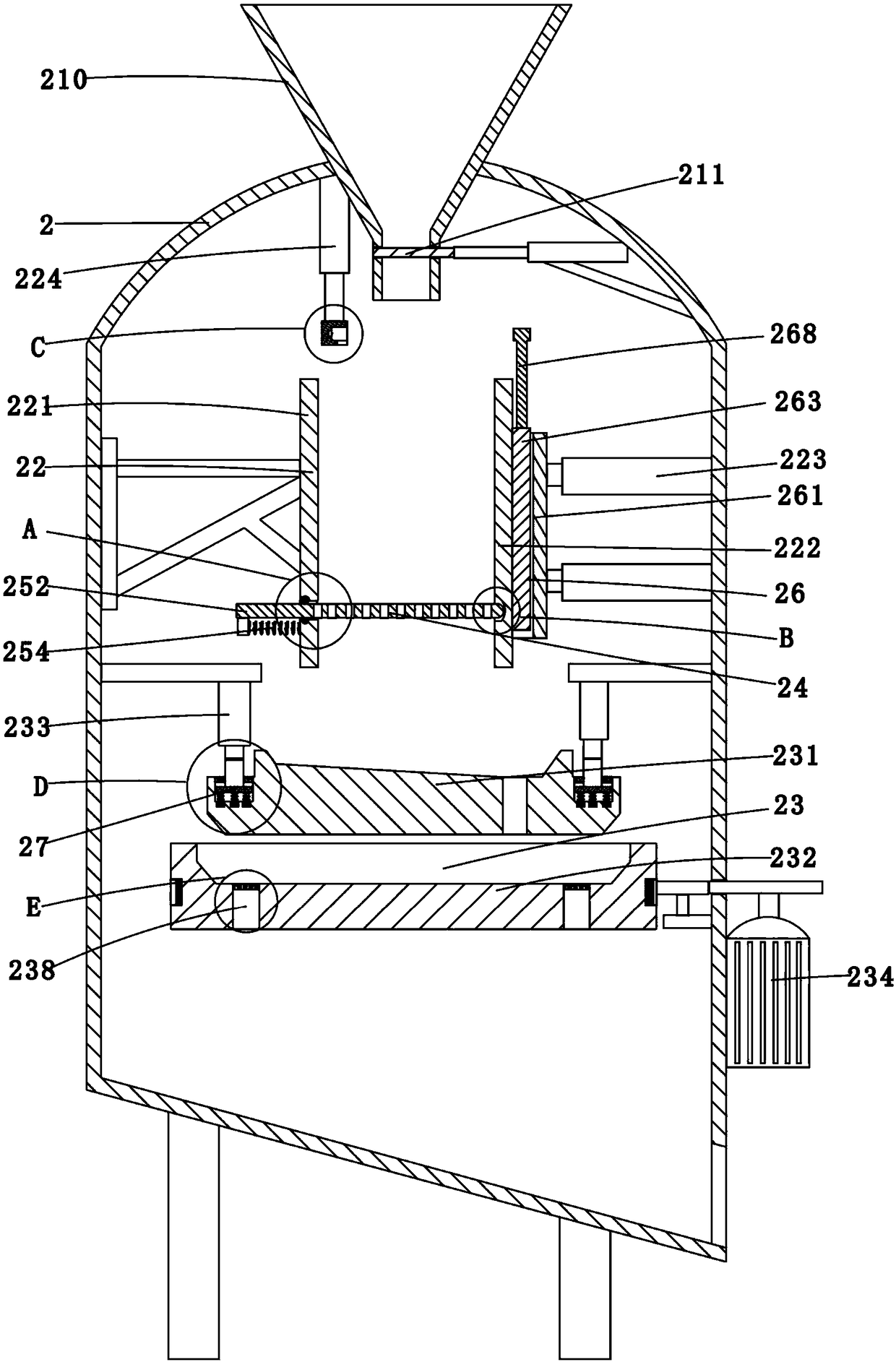

[0036] Such as Figure 1-11As shown, a device for recycling and processing household handicrafts with solid waste, including a crushing device 1, a grinding device 2, a pulping device 3 and a forming device 4, wherein the crushing device 1 includes a casing 10, a first crushing roller 11, The second crushing roller 12 and the motor 13, the first crushing roller 11 and the second crushing roller 12 are metal rollers with convex teeth on the surface, and the motor 13 drives the first crushing roller 11 and the second crushing roller through gears 12 to rotate, through the first crushing roller 11 and the second crushing roller 12, the large material is broken into small pieces; the rotation is that the first crushing roller 11 rotates clockwise, and the second crushing roller 12 is counterclockwise Rotation; after passing through the crushing device 1, the material is transported to the grinding device 2 through the conveyor belt, and the material processed by the grinding devic...

Embodiment 2

[0050] Such as Figure 12-13 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment discloses a drying device 5 for drying the slurry injected into the mould, specifically: the drying device 5 includes a box body 51, a low temperature Zone 52 and high temperature zone 53, the box body 51 is a metal box, the low temperature zone 52 and the high temperature zone 53 are two areas located in the box body 51, and the low temperature zone 52 and the high temperature zone 53 pass through A heat insulation part 54 is separated; the heat insulation part 54 comprises a heat insulation board 541, a water cooling chamber 542, a water inlet pipe 543 and a water outlet pipe 544, and the heat insulation board 541 is a high temperature resistant material board, and the water cooling chamber 542 Set on the heat insulation board 541, the water inlet pipe 543 communicates with the lower part of the water cooling chamber 542, the water outlet pipe 544 communicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com