Concrete expansion agent, concrete and preparation method thereof

A technology of concrete and expansion agent, applied in the field of concrete, can solve the problems of reducing the density of concrete, increasing the viscosity and yield shear stress of cement paste, reducing the fluidity of fresh concrete, and achieving uniform expansion and enhancement of compactness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also proposes a kind of preparation method of concrete, and this preparation method comprises the following steps:

[0046] In terms of parts by mass, 15-63 parts of expansion agent for concrete, 240-300 parts of cement, 920-1110 parts of sand, 810-1000 parts of stone, 2.1-3.6 parts of water reducing agent, and 160-175 parts of water are provided;

[0047] Mix expansion agent, cement, sand, and stone for concrete to obtain mixed base material;

[0048] Mix the water reducer and water to obtain a water reducer solution;

[0049] Add the water reducer solution into the mixed base material, stir and mix to obtain concrete.

[0050] Specifically, first weigh 15-63 parts of expansion agent for concrete, 240-300 parts of cement, 920-1110 parts of sand, 810-1000 parts of stone, 2.1-3.6 parts of water reducing agent, and 160-175 parts of water; then Concrete expansion agent, cement, sand, and stones are sequentially added to the mixer, and stirred at roo...

Embodiment 1

[0055] In parts by mass, each cubic meter of concrete contains: 300 parts of cement, 31.465 parts of expansion agent for concrete, 60 parts of active admixture, 970 parts of sand, 950 parts of stone, 165 parts of water, and 3.6 parts of water reducing agent; among them, 31.465 parts of expansion agent for concrete contain 31 parts of calcium sulfoaluminate expansion agent, 0.31 parts of sodium metaaluminate and 0.155 parts of potassium metaaluminate; 60 parts of active admixture contain 30 parts of fly ash and 30 parts of zeolite powder.

[0056] The preparation method of present embodiment concrete comprises the following steps:

[0057] Add cement, concrete expansion agent, active admixture, sand, and stone into the mixer in sequence, and stir for 2 minutes at room temperature to obtain a mixed base material;

[0058] Add the water reducer and water into the mixer in turn, stir evenly, and prepare the water reducer solution;

[0059] Slowly add the prepared water reducer so...

Embodiment 2

[0062] In terms of parts by mass, each cubic meter of concrete contains: 240 parts of cement, 28.28 parts of expansion agent for concrete, 120 parts of active admixture, 920 parts of sand, 1000 parts of stone, 170 parts of water, and 3.4 parts of water reducing agent; among them, 28.28 parts of expansion agent for concrete contain 28 parts of calcium sulfoaluminate expansion agent and 0.28 parts of sodium metaaluminate; 120 parts of active admixture contain 40 parts of fly ash and 80 parts of zeolite powder.

[0063] The preparation method of the concrete in this embodiment refers to the preparation method described in the first embodiment, and will not be repeated here.

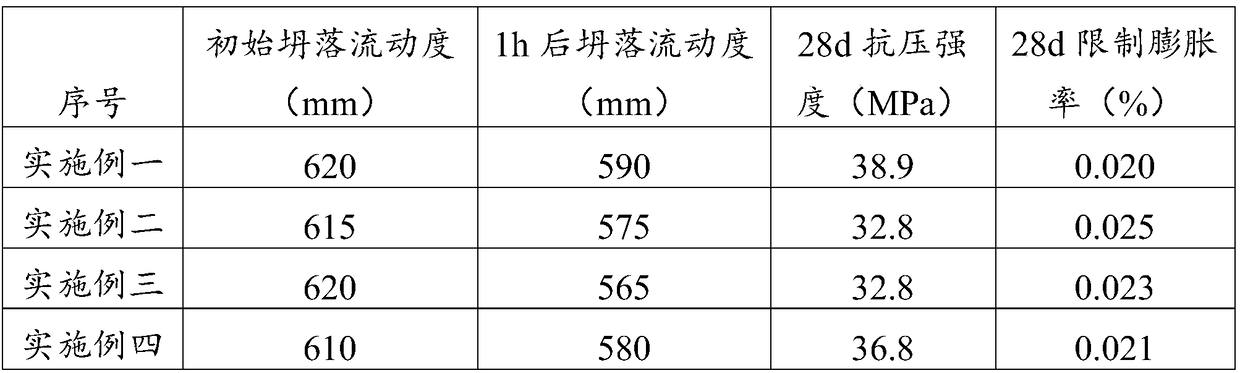

[0064] And the concrete mixed in this embodiment was poured into the mold, and the performance test was carried out to the concrete during the pouring molding process. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com