Preparation method for ambroxol hydrochloride intermediate 3,5-dibromo-2-aminobenzoic acid

A technology of aminobenzoic acid and ammonium bromide hydrochloride, which is applied in the field of preparation of ammonium bromide hydrochloride intermediate 3,5-dibromo-2-aminobenzoic acid, can solve the problems of large environmental pollution and high production cost, and achieve environmental protection Friendly, low production cost, low solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

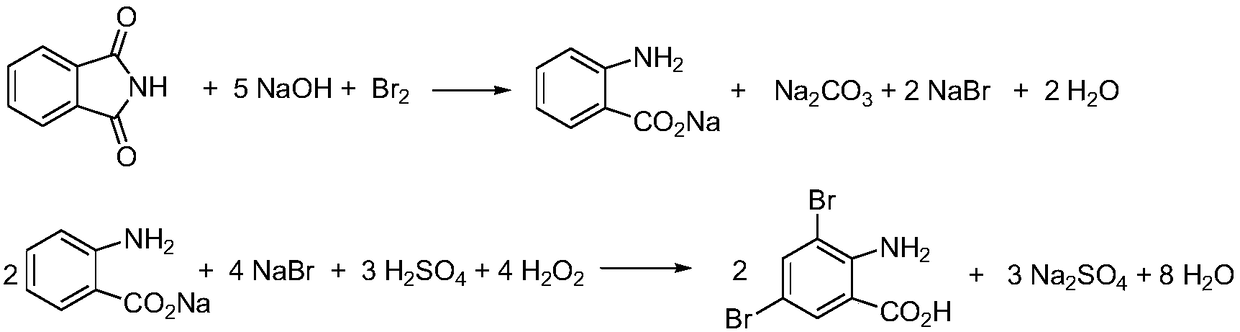

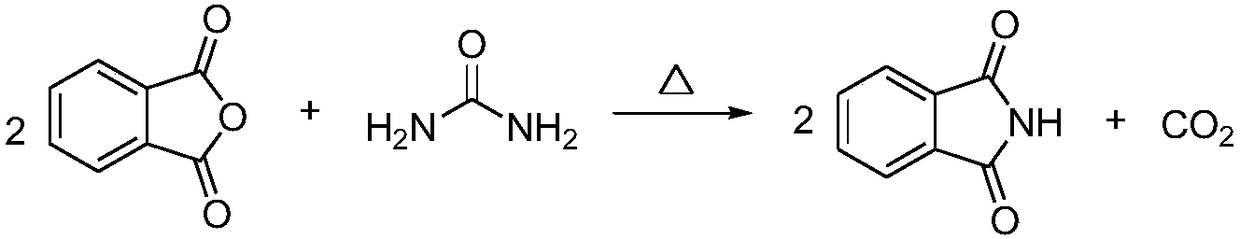

Method used

Image

Examples

Embodiment 1

[0033] At room temperature, dissolve 6.0g (0.041mol) of phthalimide and 15.6g (0.39mol) of NaOH into 80g of water, cool down to -5-0°C, add 2.4mL (0.047mol) of liquid bromine dropwise, and Insulate and react at -5~0°C for 30 minutes. Raise the temperature of the reaction system to 70°C and keep it warm for 5-10 minutes, cool to room temperature, add 50mL (0.36mol) of 50% sulfuric acid dropwise, cool down to -5-0°C, add 9.6g (0.099mol) of 35% hydrogen peroxide dropwise, and The reaction was incubated at -5~0°C for 1 h, and then raised to room temperature to continue the reaction for 11 h. Filtration, the solid was washed with 2×30mL H 2 O was washed and dried to obtain 10.9 g of 3,5-dibromo-2-aminobenzoic acid light yellow solid with a yield of 90.8%.

Embodiment 2

[0035] At room temperature, dissolve 6.0g (0.041mol) of phthalimide and 22.2g (0.39mol) of KOH into 80g of water, cool down to -5-0°C, add 2.4mL (0.047mol) of liquid bromine dropwise, and Insulate and react at -5~0°C for 30 minutes. Raise the temperature of the reaction system to 70°C and keep it warm for 5-10 minutes, cool to room temperature, add 50mL (0.36mol) of 50% sulfuric acid dropwise, cool down to -5-0°C, add 9.6g (0.099mol) of 35% hydrogen peroxide dropwise, and Insulate and react at -5~0°C for 1 h, then rise to room temperature and continue to react for 12 h. After filtration, the solid was washed with 2×30 mL H2O, and dried to obtain 10.7 g of 3,5-dibromo-2-aminobenzoic acid as a pale yellow solid, with a yield of 89.2%.

Embodiment 3

[0037] At room temperature, dissolve 6.0g (0.041mol) of phthalimide and 15.6g (0.39mol) of NaOH into 80g of water, cool down to -5~0°C, add 2.2mL (0.043mol) of liquid bromine dropwise, and Insulate and react at -5~0°C for 30 minutes. Raise the temperature of the reaction system to 70°C and keep it warm for 5-10 minutes, cool to room temperature, add 50mL (0.36mol) of 50% sulfuric acid dropwise, cool down to -5-0°C, add 9.6g (0.099mol) of 35% hydrogen peroxide dropwise, and Insulate the reaction at -5~0°C for 1 h, then rise to room temperature and continue the reaction for 10 h. After filtration, the solid was washed with 2×30 mL H2O, and dried to obtain 10.2 g of 3,5-dibromo-2-aminobenzoic acid as a pale yellow solid, with a yield of 85.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com