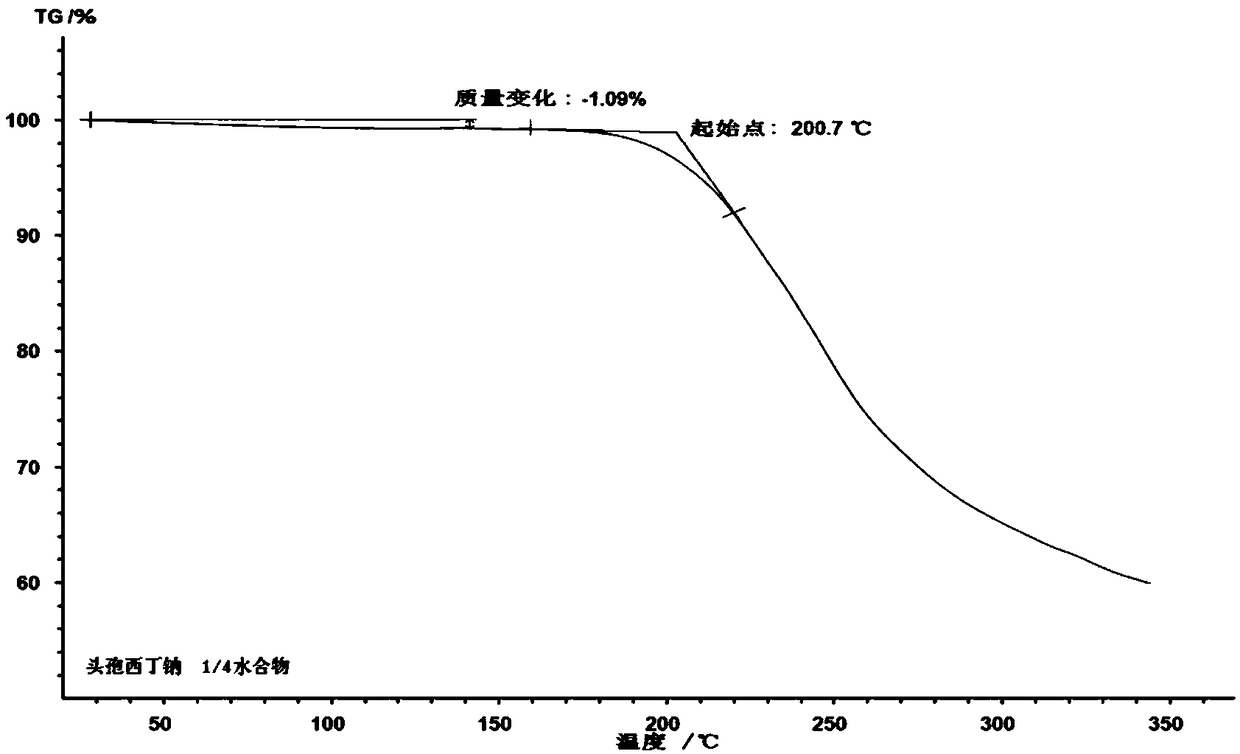

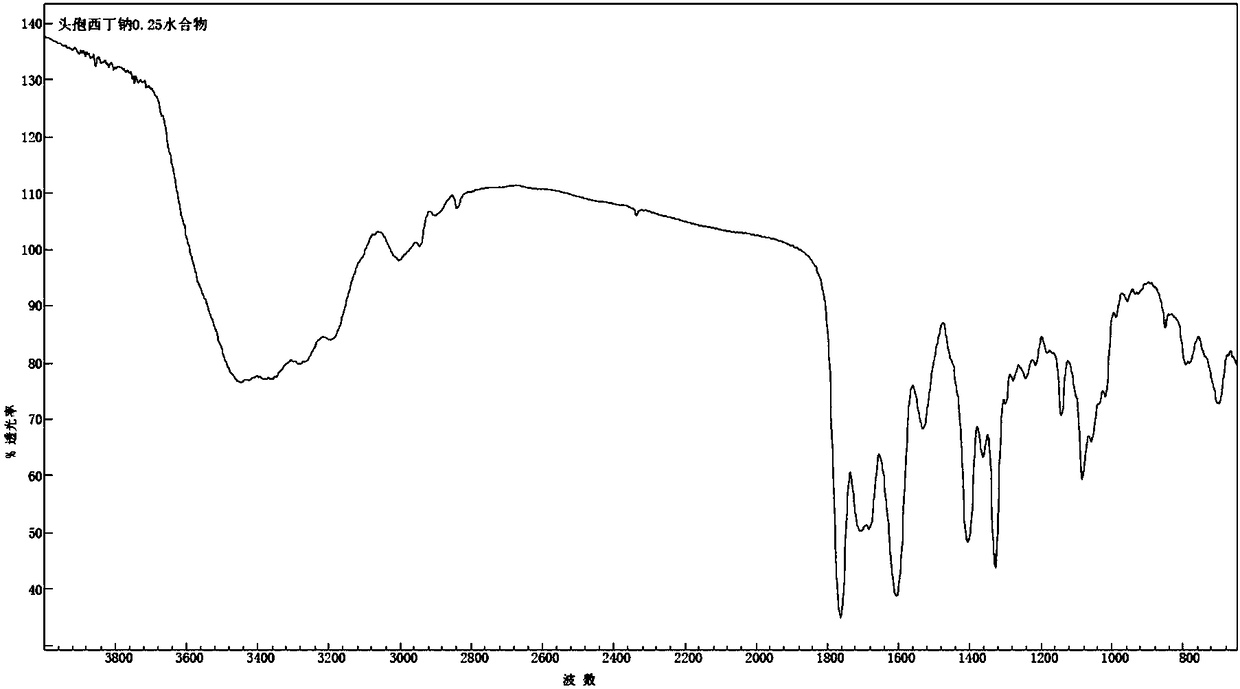

1/4 water cefoxitin sodium compound

A technology of cefoxitin sodium and its compound, which is applied in the field of 1/4 water cefoxitin sodium compound and its preparation, and can solve the problems of backward preparation method, instability between batches, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Preparation of 1 / 4 cefoxitin sodium compound

[0033] making process:

[0034] (1) Dissolve 25.71g of cefoxitin acid in 50mL of water, stir to dissolve, control the temperature at 0-5°C, add 4.0mL of triethylamine dropwise, stir well; add 0.21g of activated carbon for decolorization, filter, and wash with a small amount of water Filter cake; dropwise add a solution of 15.21 g of sodium isooctanoate and 45 mL of ethanol to the filtrate, after the addition is completed, stir, slowly add 25 mL of acetone, and an off-white solid precipitates; filter, and dry under vacuum at 40°C to obtain 26.36 g of crude cefoxitin sodium ;

[0035] (2) Dissolve 26.36 g of the crude product of cefoxitin sodium in 50 mL of water, slowly add 25 mL of acetone to it, control the temperature at 0 to 3° C., and let stand for crystallization for 1.5 h; filter, and wash the filtrate with 40 mL of acetone × 2, After vacuum drying at ℃ for 55 min, 25.79 g of 1 / 4 cefoxitin sodium compo...

Embodiment 2

[0040] Embodiment 2: Preparation of 1 / 4 cefoxitin sodium compound

[0041] making process:

[0042] (1) Dissolve 25.69g of cefoxitin acid in 50mL of water, stir to dissolve, control the temperature at -5~0°C, add 4.0mL of triethylamine dropwise to it, and stir well; add 0.24g of activated carbon for decolorization, filter, and use a small amount of Wash the filter cake with water; add dropwise a solution of 5.54 g of sodium hydroxide and 17 mL of ethanol to the filtrate, after adding, stir, slowly add 25 mL of acetone, and a off-white solid precipitates; filter, and dry in vacuo at 35°C to obtain crude cefoxitin sodium 26.53 g;

[0043] (2) Dissolve 26.53g of crude cefoxitin sodium in 50mL of water, slowly add 25mL of acetone to it, control the temperature at 5-8°C, let stand for crystallization for 2h; Vacuum dried for 55 minutes to obtain 25.68 g of 1 / 4 cefoxitin sodium compound.

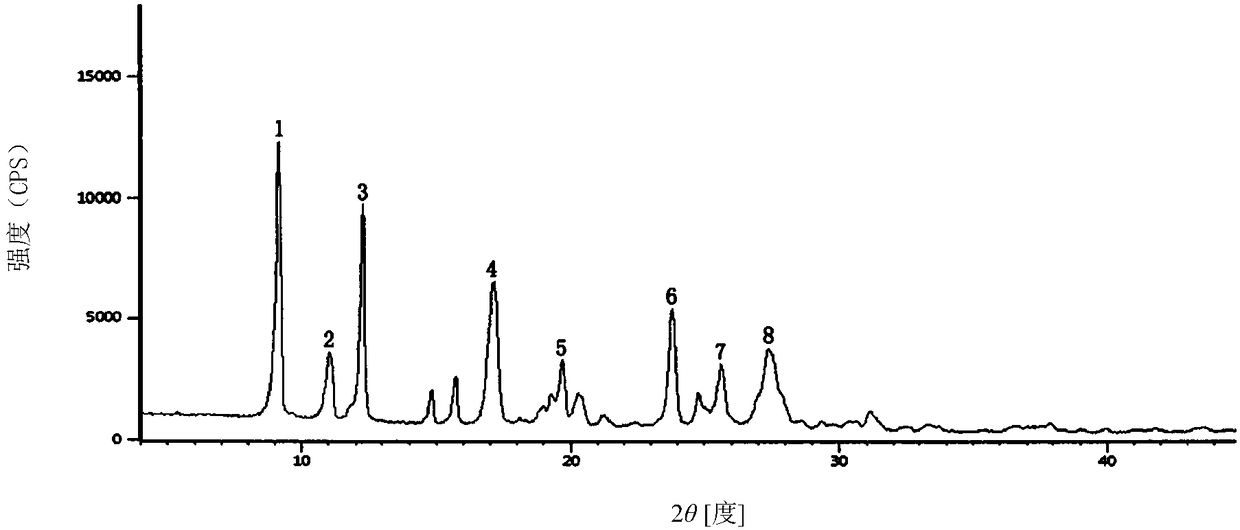

[0044] The powder X-ray diffraction pattern has characteristic diffraction peaks at the dif...

Embodiment 3

[0048] Embodiment 3: Preparation of 1 / 4 cefoxitin sodium compound

[0049] making process:

[0050] (1) Dissolve 25.65g of cefoxitin acid in 50mL of water, stir to dissolve, control the temperature at 5-8°C, add 4.0mL of triethylamine dropwise, and stir well; add 0.18g of activated carbon for decolorization, filter, and wash with a small amount of water Filter cake; dropwise add the solution formed by 15.24 g of sodium isooctanoate and 45 mL of ethanol to the filtrate, after the addition is completed, stir, slowly add 25 mL of acetone, and an off-white solid precipitates; filter, and dry in vacuo at 45°C to obtain 26.57 g of crude product of cefoxitin sodium ;

[0051] (2) Dissolve 26.57 g of the crude product of cefoxitin sodium in 50 mL of water, slowly add 25 mL of acetone to it, control the temperature at -3 to 0° C., let stand for crystallization for 2 h; filter, wash the filtrate with 40 mL of acetone × 2, and ℃ vacuum drying for 55min to obtain 1 / 4 cefoxitin sodium co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com