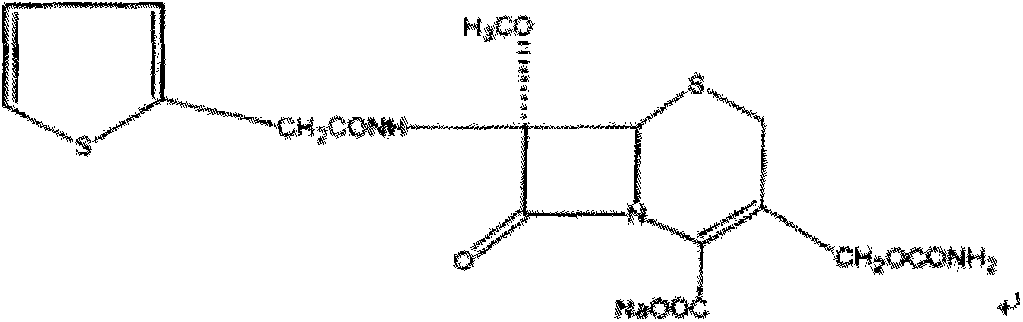

Cefoxitin sodium agent and preparation method thereof

A technology for cefoxitin sodium and injections, which is applied in pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., and can solve problems such as content decline, injection impurity content increase, and drug cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

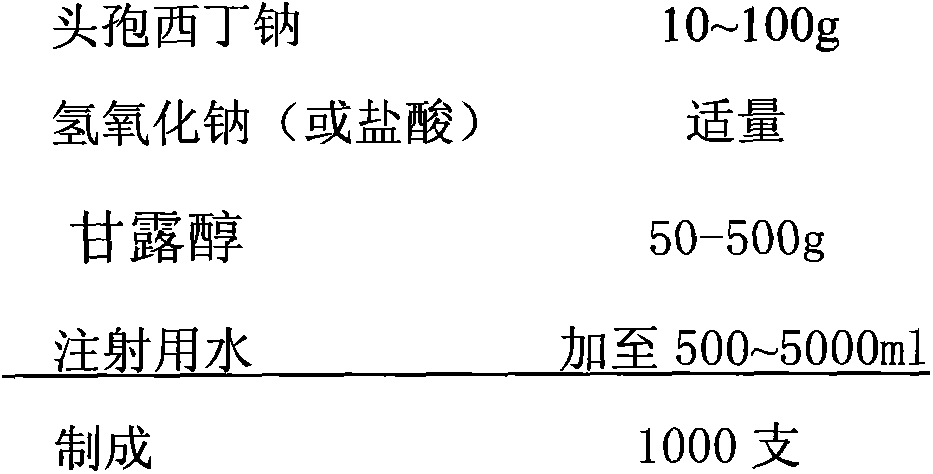

[0026] Example 1 1000 cefoxitin sodium freeze-dried powder injections

[0027]

[0028]

[0029] In a clean area, take a small amount of sodium hydroxide and add it to a small amount of water for injection, stir to dissolve, and set aside; add the prescribed amount of cefoxitin sodium to an appropriate amount of water for injection, stir and dissolve as solution I; adjust the pH to about 6.6 with sodium hydroxide solution , to prepare solution II; add prescription amount of mannitol to solution II, stir and dissolve to obtain solution III. Weigh 2.4g of activated carbon and add an appropriate amount of water for injection and stir well, then add it to solution III, add water for injection to the full amount, stir and circulate for more than 15 minutes, first decarbonize by coarse filtration, and then fine filter through a 0.22μm filter membrane to obtain the essence The filtrate is tested for content, pH value, endotoxin, visible foreign matter and other items. After pas...

Embodiment 2

[0030] Example 2 1000 cefoxitin sodium freeze-dried powder injections

[0031]

[0032] In the clean area, first add the prescribed amount of cefoxitin sodium into an appropriate amount of water for injection, stir and dissolve, as solution I; adjust the pH to about 6.3 with hydrochloric acid, as solution II; add the prescribed amount of mannitol to solution II, Stir to dissolve as solution III. Take 20g of activated carbon and add an appropriate amount of water for injection and stir well, add it to solution III, add water for injection to the full amount, stir and circulate for more than 15 minutes, first decarbonize by coarse filtration, and then fine filter through a 0.22μm filter membrane, and take the fine filtrate for content, pH Value, endotoxin, visible foreign matter and other items are tested, and after passing the test, it is filled and freeze-dried, and the freeze-drying process is as follows: the shelf temperature is set at -35°C to -50°C for pre-freezing, and...

Embodiment 3

[0033] Example 3 1000 cefoxitin sodium freeze-dried powder injections

[0034]

[0035]

[0036] In the clean area, first add the prescribed amount of cefoxitin sodium into an appropriate amount of water for injection, stir and dissolve, and make it solution I; adjust the pH to about 6.5 with sodium hydroxide, and make it solution II; add the prescribed amount of manna to solution II Alcohol, stirred to dissolve, as solution III. Take 6g of activated carbon and add an appropriate amount of water for injection, stir well, add it to solution III, add water for injection to the full amount, stir and circulate for more than 15 minutes, first decarbonize by coarse filtration, and then fine filter through a 0.22μm filter membrane, and take the fine filtrate for content, pH Value, endotoxin, visible foreign matter and other items are tested, and after passing the test, it is filled and freeze-dried, and the freeze-drying process is as follows: the shelf temperature is set at -35°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com