Method for extracting sericin from refined reeling mill silk liquid and ultrafiltration membrane device

A sericin and refining liquid technology, which is applied in the fields of peptide preparation, chemical instruments and methods, animal/human peptides, etc., can solve the problems of equipment damage, easy blockage of ultrafiltration membranes, and reduced use level of sericin, etc. Achieve high recovery rate, improve recycling rate and reduce loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

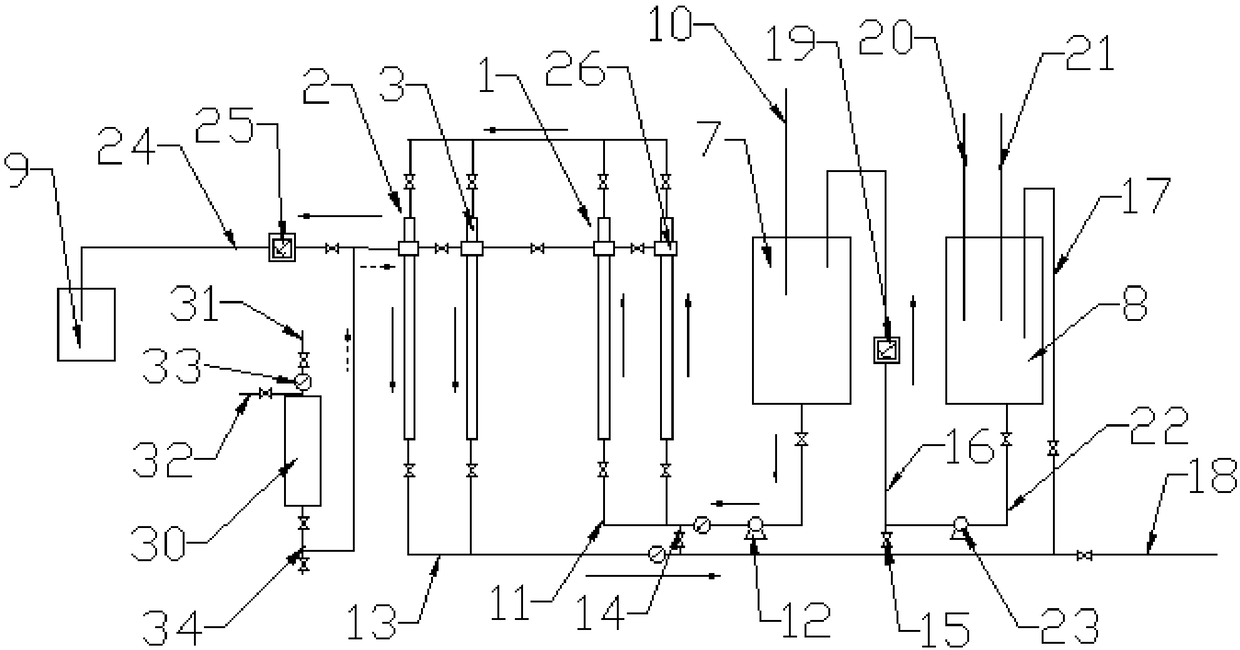

[0032] A method for extracting sericin from the refined liquid of mulberry bark, comprising the following steps:

[0033] (1) Sangtiao spit refining liquid is pretreated through 300 mesh, 500 mesh and 800 mesh vibrating sieves successively to remove impurities with larger particle sizes in the refining wastewater to obtain the filtrate;

[0034] (2) The filtrate obtained in step (1) is finely removed with an ultrafiltration membrane with a molecular weight cut-off of 40,000D, and at the same time, sericin with a molecular weight cut-off greater than 40KD is put into the concentrated solution, and finally concentrated to the total volume of the filtrate 10% of the permeate is collected, and the permeate flow rate is 180L / h·m 2 , pressure 0.25MPa, temperature 27°C-32°C;

[0035] (3) Concentrate the permeate in step (2) with a nanofiltration membrane with a molecular weight cut-off of 8000D, and the flow rate of the permeate is 300L / h m 2 , pressure 0.45-0.55MPa, temperature 27...

Embodiment 2

[0054] The present embodiment is basically the same as Example 1, except that: the concentrated solution in step (2) adds papain and deionized water, and the mass ratio of the concentrated solution to papain and deionized water is 100:0.4:800, Enzymolyze at 55-65°C for 40-55min, then heat up to 90-95°C to heat and kill the enzyme, then cool to 27°C-32°C, and carry out steps (2), (3) and (4) in turn for the enzymolysis solution ), to obtain sericin powder.

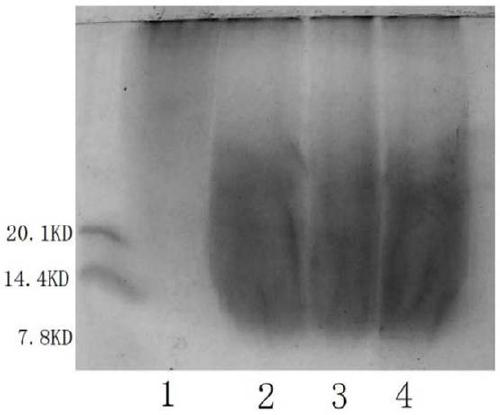

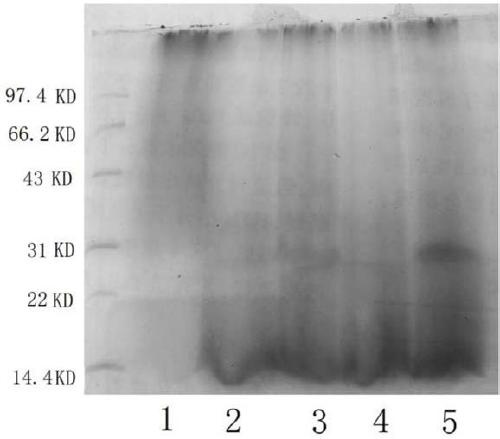

[0055] Use 12% separation gel for electrophoresis test, see figure 2 As shown, band 1 is the electrophoresis band of sericin protein with a molecular weight of 40KD or more, and bands 2-5 are the electrophoresis bands of sericin protein with a molecular weight of 40KD or more hydrolyzed with papain. After the membrane is refined and slag removed, the molecular weight of sericin in the concentrated solution is above 40KD, and the molecular weight of sericin obtained by hydrolysis with papain is mainly concentrated between ...

Embodiment 3

[0057] This embodiment is basically the same as the second embodiment, except that the mass ratio of the concentrate to papain and deionized water is 100:0.5:800.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com