Biodegradable foaming material and preparation method thereof

A technology of biodegradable and foamed materials, applied in the field of biodegradable foamed materials and their preparation, can solve the problem of lack of carrier materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

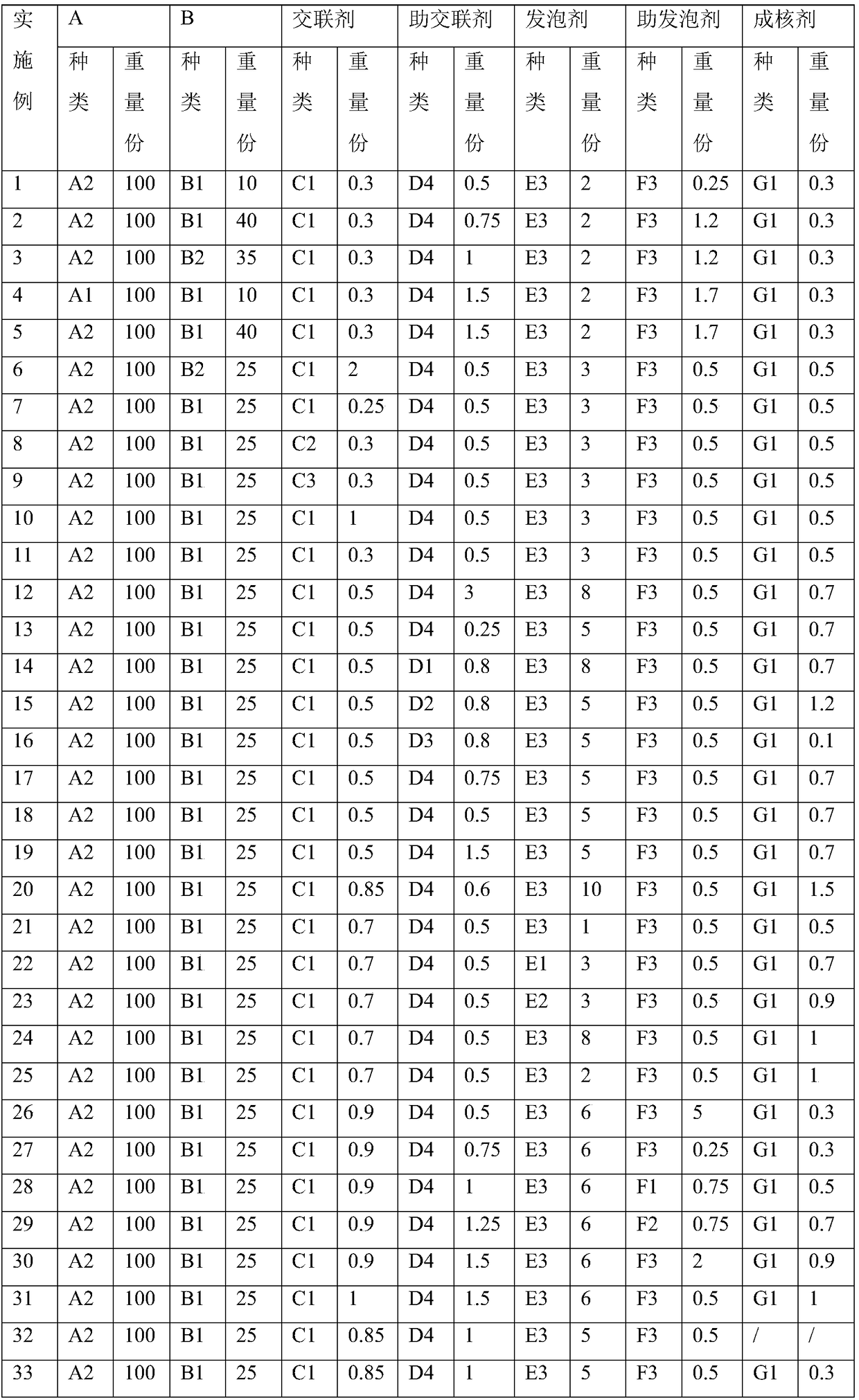

[0092] According to the raw materials and weight ratio shown in Table 1, the biodegradable foaming material of the present invention was prepared by referring to the following steps.

[0093] 1. Blend biodegradable polymer A, biodegradable polymer B, co-crosslinking agent, foaming agent, pro-foaming agent and nucleating agent according to their weight parts at 160°C for 50s.

[0094] 2. Then add the cross-linking agent in corresponding parts by weight, and continue to blend at 160°C for 190s to obtain a billet.

[0095] 3. Put the blank into the molding machine for molding. The process conditions are controlled as follows: 195°C, 8min, 5MPa. After 2 minutes of mold opening (mold opening and foaming), the sample was quickly put into room temperature water for quenching to obtain a biodegradable foam material with a thickness of 8mm.

[0096] 4. Put the dried biodegradable foaming material in the aluminum hydroxide colloidal solution for 6 hours, rinse it with running water, a...

Embodiment 6~32、34~37

[0098] According to the raw materials and weight ratio shown in Table 1, the biodegradable foaming material of the present invention was prepared by referring to the following steps.

[0099] 1. Blend biodegradable polymer A, biodegradable polymer B, co-crosslinking agent, foaming agent, pro-foaming agent and nucleating agent according to their weight parts at 160°C for 50s.

[0100] 2. Then add the cross-linking agent in corresponding parts by weight, and continue to blend at 160°C for 190s to obtain a billet.

[0101] 3. Put the blank into the molding machine for molding. The process conditions are controlled as follows: 195°C, 8min, 5MPa. After 2 minutes of mold opening (mold opening and foaming), the sample was quickly put into room temperature water for quenching to obtain a biodegradable foam material with a thickness of 8 mm.

[0102] 4. Put the dried biodegradable foaming material in the colloidal solution of ferroferric oxide for 6 hours, rinse it with flowing water...

Embodiment 5

[0104] According to the raw materials and weight ratio shown in Table 1, the biodegradable foaming material of the present invention was prepared by referring to the following steps.

[0105] 1. Blend biodegradable polymer A, biodegradable polymer B, co-crosslinking agent, foaming agent, pro-foaming agent and nucleating agent according to their weight parts at 160°C for 50s.

[0106] 2. Then add the cross-linking agent in corresponding parts by weight, and continue to blend at 160°C for 190s to obtain a billet.

[0107] 3. Put the blank into the molding machine for molding. The process conditions are controlled as follows: 195°C, 8min, 5MPa. After the mold is closed and foamed, the sample is rapidly cooled in water at room temperature to obtain a biodegradable foamed material with a thickness of 8 mm.

[0108] 4. Put the dried biodegradable foaming material in the colloidal solution of ferroferric oxide for 6 hours, rinse it with flowing water, and then dry it at 60° C. to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com