Water spraying sheet for high-vicat nuclear power and manufacturing method of water spraying sheet

A production method and high-dimensional card technology, applied in the field of water spray sheet, can solve the problems of reduced tensile strength and elongation at break, limited pressure bearing capacity, and affecting the performance of water spray sheet, so as to increase chemical stability and improve Effects of increased heat resistance and irregularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

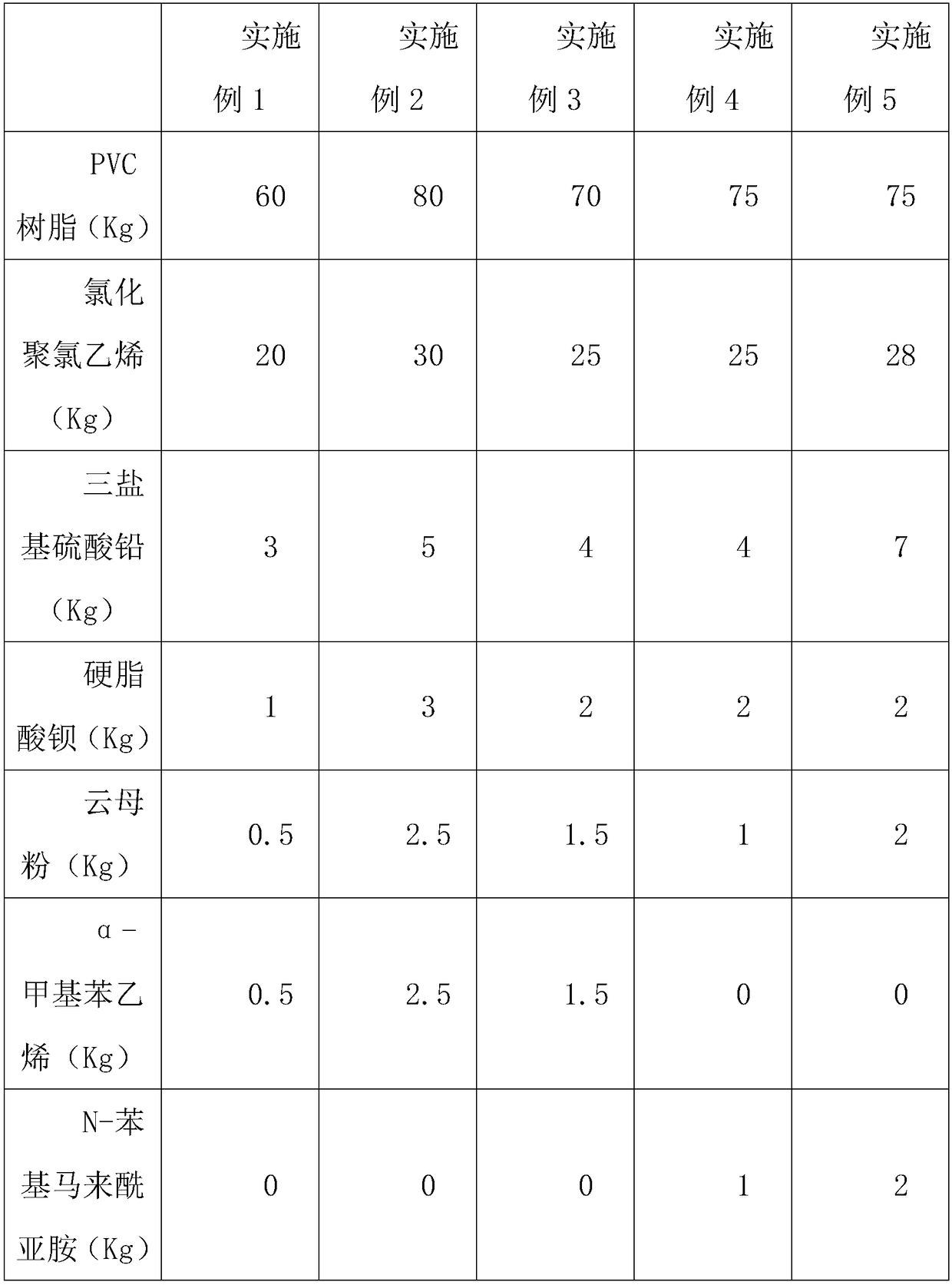

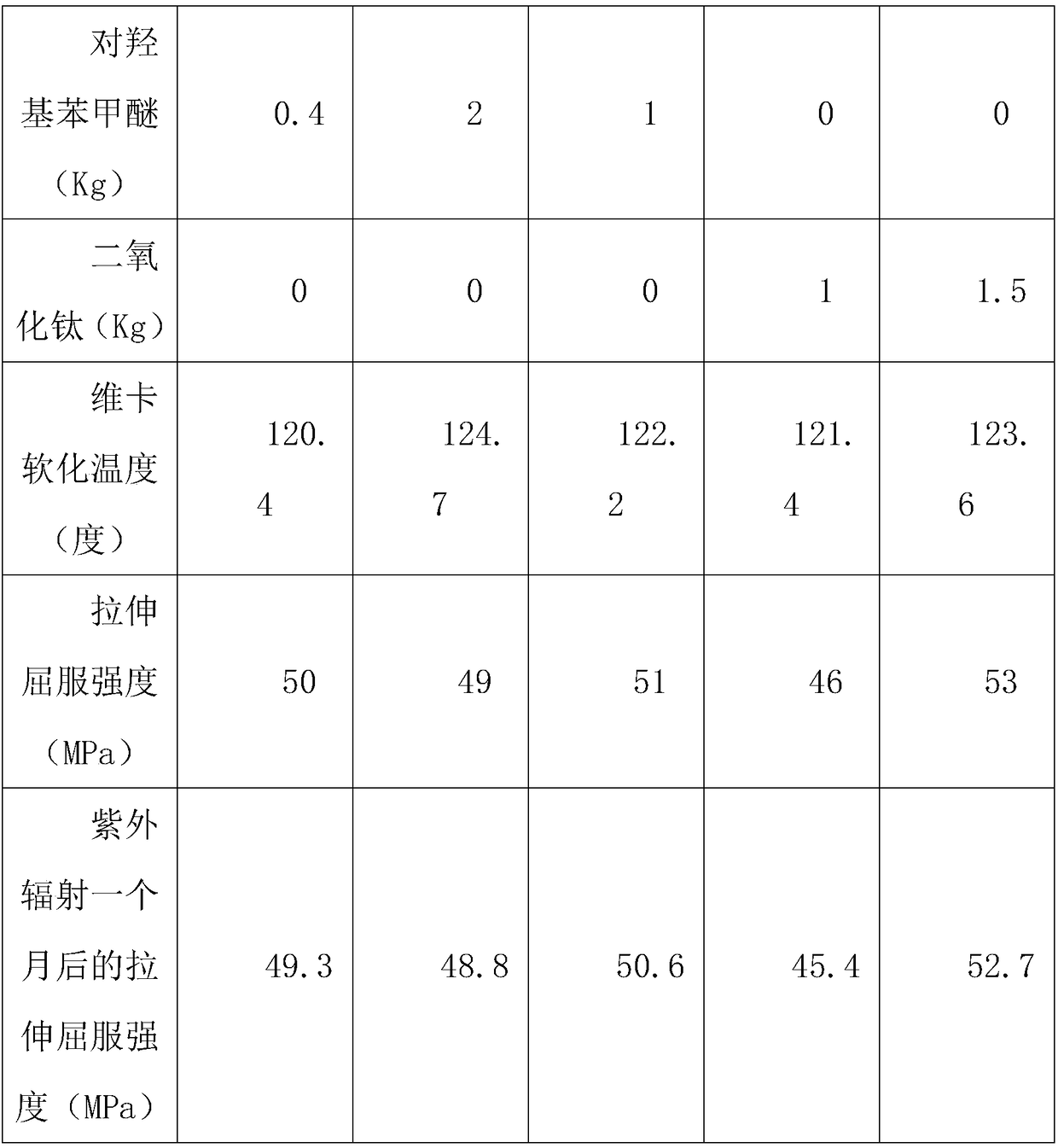

Embodiment 1

[0042] A high-vicat water spray sheet for nuclear power, the components of which include PVC resin, chlorinated polyvinyl chloride, tribasic lead sulfate, barium stearate, inorganic fillers, and ultraviolet inhibitors.

[0043] The inorganic filler is mica powder.

[0044] It also includes polymer heat-resistant modifiers.

[0045] Each component is composed of the following mass Kg:

[0046] PVC resin: 60Kg

[0047] Chlorinated polyvinyl chloride: 20Kg

[0048] Tribasic lead sulfate: 3Kg

[0050] Inorganic filler: 0.5Kg

[0051] UV inhibitor: 0.5Kg

[0052] Polymer heat-resistant modifier: 0.4Kg.

[0053] The high-vicat water spray sheet for nuclear power includes PVC resin, chlorinated polyvinyl chloride, tribasic lead sulfate, barium stearate, inorganic fillers, polymer heat-resistant modifiers, and ultraviolet inhibitors through its components. Chlorinated polyvinyl chloride is obtained after chlorination of PVC resin. The irregularity...

Embodiment 2

[0070] Basically the same as Example 1, the difference is that a high-vicat water shower sheet for nuclear power, its components include PVC resin, chlorinated polyvinyl chloride, tribasic lead sulfate, barium stearate, inorganic fillers, UV inhibitors.

[0071] The inorganic filler is mica powder.

[0072] It also includes polymer heat-resistant modifiers.

[0073] Each component is composed of the following mass Kg:

[0074] PVC resin: 80Kg

[0075] Chlorinated polyvinyl chloride: 30Kg

[0076] Tribasic lead sulfate: 5Kg

[0077] Barium stearate: 3Kg

[0078] Inorganic filler: 2.5Kg

[0079] UV inhibitor: 2.5Kg

[0080] Polymer heat-resistant modifier: 2Kg.

Embodiment 3

[0082] Basically the same as Example 1, the difference is that a high-vicat water shower sheet for nuclear power, its components include PVC resin, chlorinated polyvinyl chloride, tribasic lead sulfate, barium stearate, inorganic fillers, UV inhibitors.

[0083] The inorganic filler is mica powder.

[0084] It also includes polymer heat-resistant modifiers.

[0085] Each component is composed of the following mass Kg:

[0086] PVC resin: 70Kg

[0087] Chlorinated polyvinyl chloride: 25Kg

[0088] Tribasic lead sulfate: 4Kg

[0089] Barium stearate: 2Kg

[0090] Inorganic filler: 1.5Kg

[0091] UV inhibitor: 1.5Kg

[0092] Polymer heat-resistant modifier: 1Kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com