Unsaturated polyester composite material and method for preparing same

A polyester composite material and unsaturated technology, applied in the field of unsaturated polyester composite material and its preparation, can solve the problems of large amount of aluminum hydroxide and continuous glass fiber mat, difficulty in realizing lightweight materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing an unsaturated polyester composite material in an embodiment includes the following steps S110-S130:

[0026] S110, mixing the unsaturated polyester, release agent, initiator, flame retardant and foaming agent to obtain a premix.

[0027] Among them, 100 parts by mass of unsaturated polyester, 1-3 parts by mass of release agent, 20-40 parts by mass of flame retardant, 0.2-0.5 parts by mass of initiator, and 1-10 parts by mass of foaming agent.

[0028] Further, the release agent is at least one selected from zinc stearate, magnesium stearate and glycidyl lauryl ester.

[0029] Further, the flame retardant is a combination of aluminum hydroxide, phosphate flame retardant and graphene oxide.

[0030] Further, the mass ratio of aluminum hydroxide, phosphate flame retardant and graphene oxide in the flame retardant is 10-25:9-13.5:0.5-1.5.

[0031] In this embodiment, the phosphoric acid ester flame retardant is dimethyl methylphosphonate (DMMP). T...

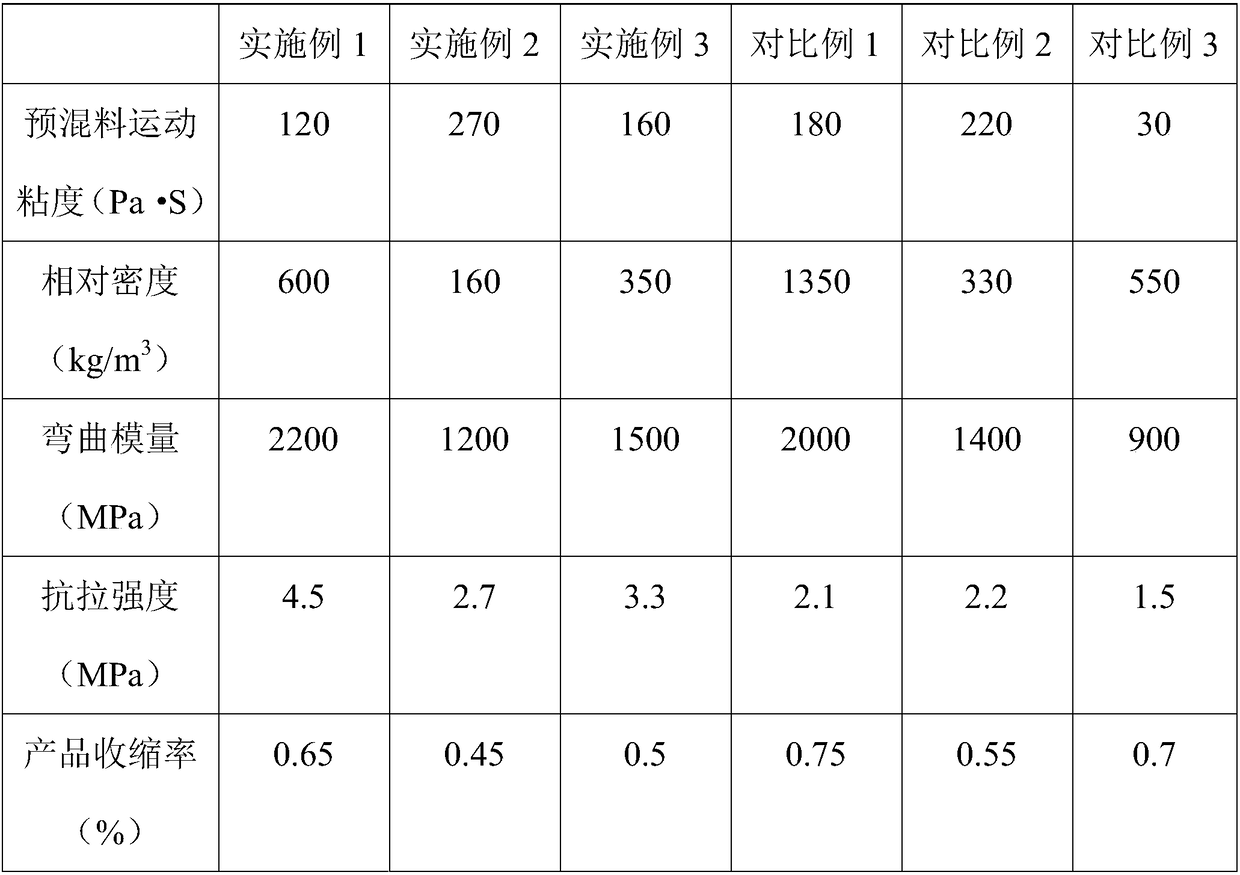

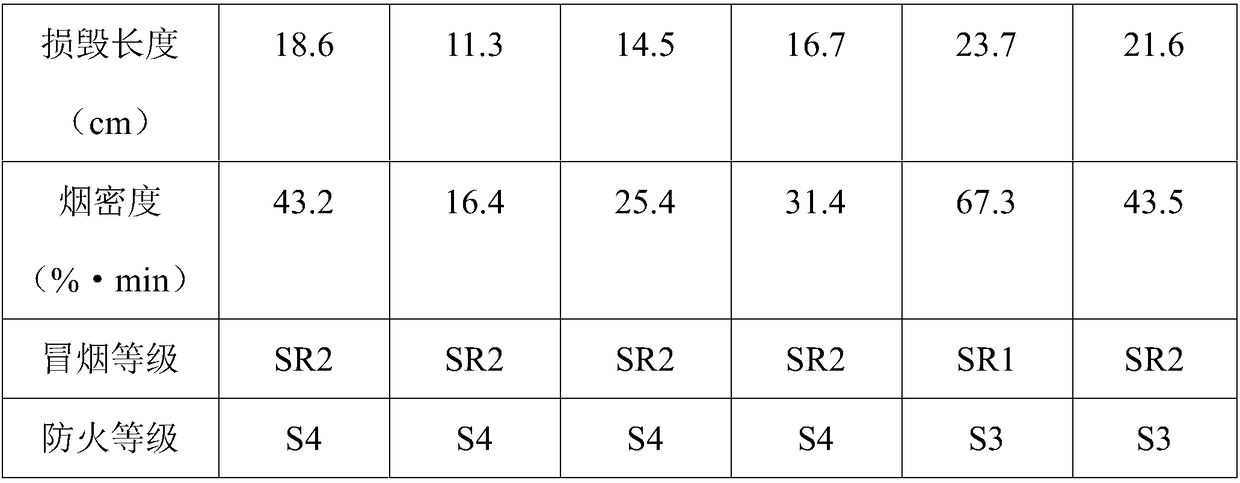

Embodiment 1

[0052] Mix 100kg of unsaturated polyester, 2kg of zinc stearate, 0.2kg of tert-butyl peroxybenzoate, 9.5kg of DMMP, 0.5kg of graphene oxide, 10kg of aluminum hydroxide and 1kg of 2,2'-azobisisobutyronitrile , to obtain the premix.

[0053] The premixed material was added from the main feeding port of the single-screw extruder, 10 kg of carbon fiber was added from the side feeding port, and extruded from the die by the screw to obtain the blended material. Wherein, the extrusion temperature of the single-screw extruder is 40° C., and the residence time is 2 minutes; the temperature of the die head is 55° C., and the residence time is 1 minute.

[0054] The blended material is heated and cured in a high-temperature oven to obtain an unsaturated polyester composite material. Wherein the temperature of the high-temperature drying tunnel is 95° C., and the residence time is 9 minutes.

Embodiment 2

[0056] Mix 100kg of unsaturated polyester, 2kg of zinc stearate, 0.5kg of tert-butyl peroxybenzoate, 13.5kg of DMMP, 1.5kg of graphene oxide, 25kg of aluminum hydroxide and 10kg of 2,2'-azobisisobutyronitrile , to obtain the premix.

[0057] The premixed material was added from the main feeding port of the single-screw extruder, and 40kg of glass fiber was added from the side feeding port, and extruded from the die by the screw to obtain the blended material. Wherein, the extrusion temperature of the single-screw extruder is 50° C., and the residence time is 4 minutes; the temperature of the die head is 65° C., and the residence time is 2 minutes.

[0058] The blended material is heated and cured in a high-temperature oven to obtain an unsaturated polyester composite material. Wherein the temperature of the high-temperature drying tunnel is 105° C., and the residence time is 11 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Damage length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com