Building basement concrete waterproof construction method

A construction method and technology for basement, applied in construction, infrastructure engineering, protection devices, etc., can solve the problems of poor waterproof effect, easy damage of waterproof layer, limited waterproof performance, etc., to achieve good waterproof effect, strong wear resistance, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

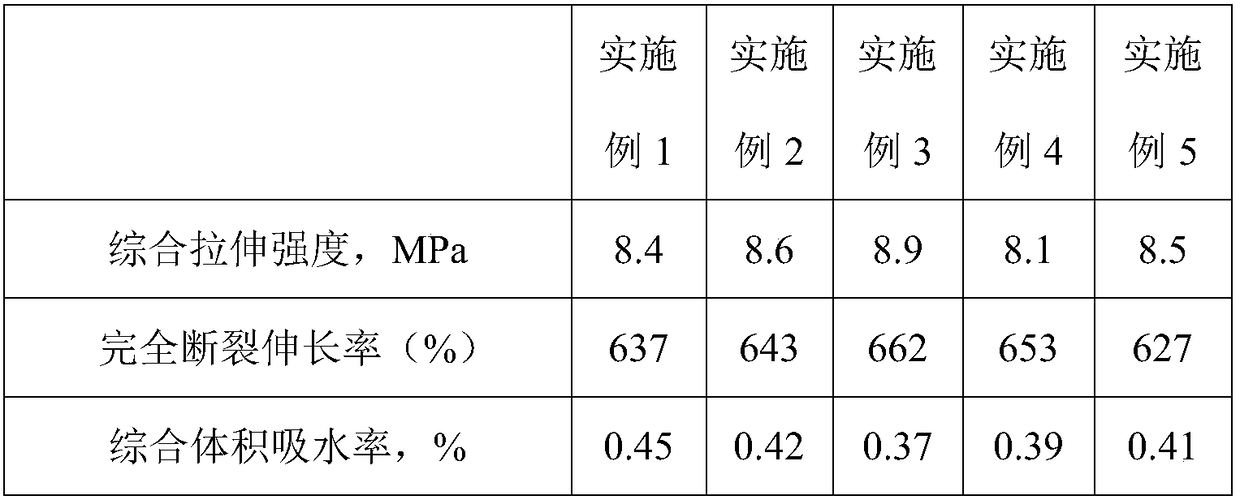

Examples

Embodiment 1

[0022] A concrete waterproof construction method for a building basement is characterized in that it comprises the following steps:

[0023] 1) Treat the concrete surface of the basement, and then spray primer on the treated concrete surface;

[0024] 2) Use waterproof glue to lay waterproof membrane on the concrete surface after spraying primer;

[0025] 3) Spray polyurethane waterproof coating on the concrete surface where waterproof coiled material is laid;

[0026] The waterproof coiled material includes the following raw materials in parts by weight: 80 parts of EPDM rubber, 30 parts of alkyd resin, 20 parts of carbon black, 10 parts of trimellitate, 8 parts of zinc carbonate, and dichlorobenzene peroxide 2 parts of formyl, 6 parts of dibutyl phthalate, 3 parts of dibutyl sebacate, 2 parts of azodicarbonamide, 3 parts of softener, 1 part of antioxidant, 1 part of coagulant.

[0027] Wherein, the preparation method of the waterproof membrane includes the following steps:

[0028] 1)...

Embodiment 2

[0033] A concrete waterproof construction method for a building basement is characterized in that it comprises the following steps:

[0034] 1) Treat the concrete surface of the basement, and then spray primer on the treated concrete surface;

[0035] 2) Use waterproof glue to lay waterproof membrane on the concrete surface after spraying primer;

[0036] 3) Spray polyurethane waterproof coating on the concrete surface where waterproof coiled material is laid;

[0037] The waterproof membrane includes the following raw materials in parts by weight: 85 parts of EPDM rubber, 35 parts of alkyd resin, 22 parts of carbon black, 12 parts of trimellitate, 10 parts of zinc carbonate, and dichlorobenzene peroxide 3 parts of formyl, 10 parts of dibutyl phthalate, 6 parts of dibutyl sebacate, 3.5 parts of azodicarbonamide, 4.5 parts of softener, 1.8 parts of antioxidant, 1.8 parts of coagulant.

[0038] Wherein, the preparation method of the waterproof membrane includes the following steps:

[003...

Embodiment 3

[0044] A concrete waterproof construction method for a building basement is characterized in that it comprises the following steps:

[0045] 1) Treat the concrete surface of the basement, and then spray primer on the treated concrete surface;

[0046] 2) Use waterproof glue to lay waterproof membrane on the concrete surface after spraying primer;

[0047] 3) Spray polyurethane waterproof coating on the concrete surface where waterproof coiled material is laid;

[0048] The waterproof membrane includes the following raw materials in parts by weight: 90 parts of EPDM rubber, 40 parts of alkyd resin, 25 parts of carbon black, 14 parts of trimellitate, 12 parts of zinc carbonate, and benzene dichloroperoxide 5 parts of formyl, 10 parts of dibutyl phthalate, 4 parts of dibutyl sebacate, 3 parts of azodicarbonamide, 4 parts of softener, 1.5 parts of antioxidant, 1.5 parts of coagulant.

[0049] Wherein, the preparation method of the waterproof membrane includes the following steps:

[0050] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com