A solid-state laser with zero heat generation in the whole pump range

A solid-state laser and pumping technology, which is applied in the laser field, can solve problems that cannot meet the needs of industry and measurement, and achieve the effects of superior structure and stability, small size, and improved light-to-light conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

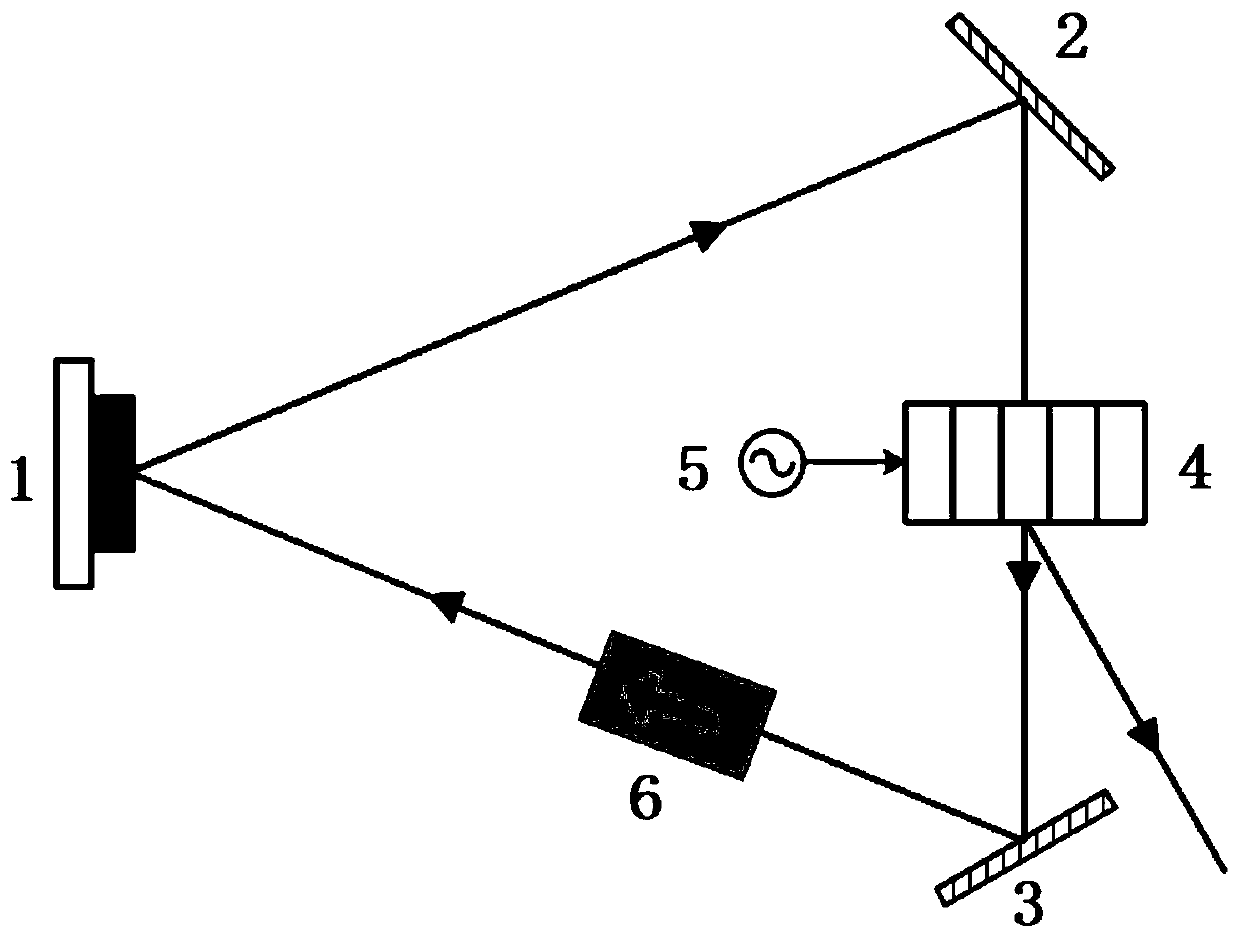

[0048] figure 1 Schematic diagram of the structure of the solid-state laser provided by Embodiment 1 of the present invention, such as figure 1 As shown, it includes a disc 1 , a first plane mirror 2 , a second plane mirror 3 , an acousto-optic crystal 4 , a driving power source 5 and an optical isolator 6 .

[0049] The material of disc 1 is Yb:YAG crystal with a diameter of 15mm and a thickness of 200um. The front of the disc is coated with a high-transparency film, and the back is coated with a high-reflection film. The corresponding wavelengths of the film systems are 1030nm and 1064nm, and the reflectivity is 99.95%. and 99.95%. Both the first plane mirror 2 and the second plane mirror 3 are 1064nm high reflection mirrors, and the reflectivity is 99.99%. Acousto-optic crystal 4 has a quality factor of 7.5e -15 the s 3 / kg; piezoelectric transducer length L = 1cm, width H = 0.3cm; by diffraction efficiency The ultrasonic intensity Is generated by the required driving...

Embodiment 2

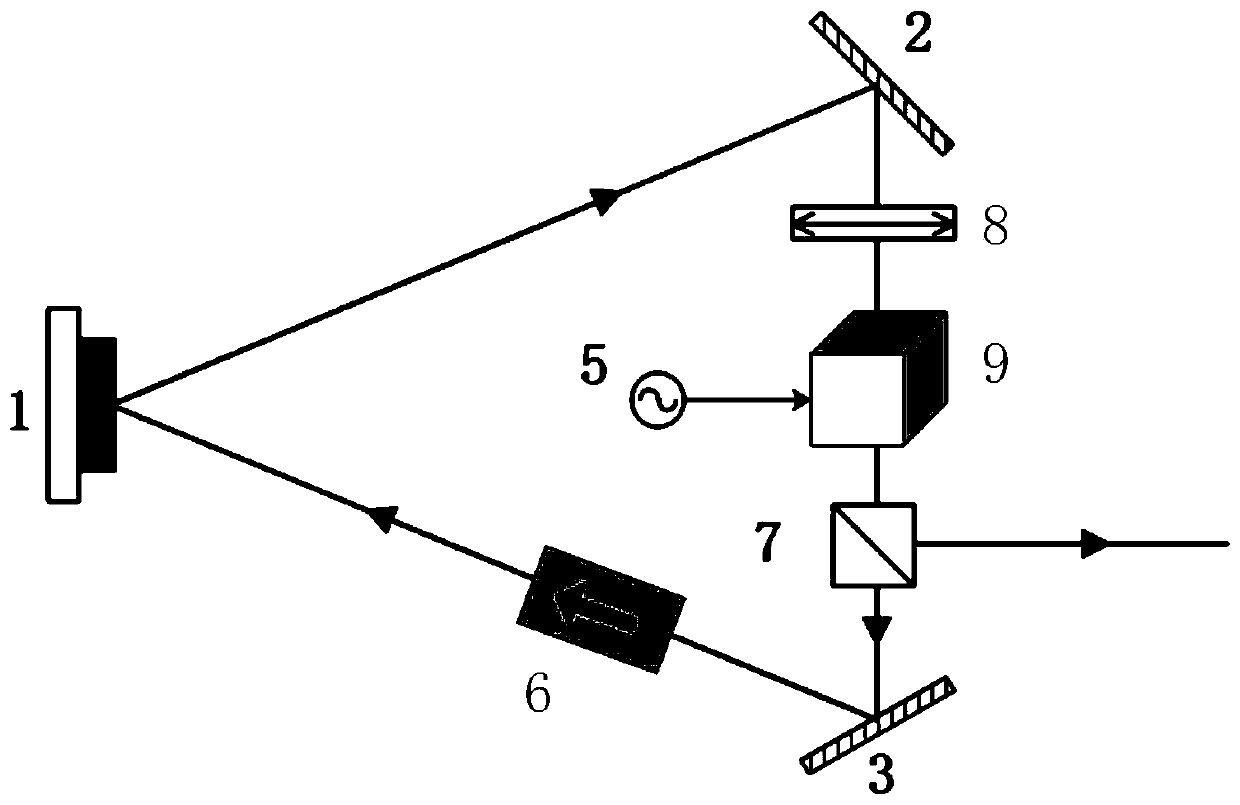

[0053] image 3 It is a schematic structural diagram of the solid-state laser provided by Embodiment 2 of the present invention, such as image 3 As shown, it includes a disc 1 , a first plane mirror 2 , a second plane mirror 3 , an electro-optic crystal 9 , a driving power supply 5 , a polarizer 8 , a polarizing beam splitter 7 , and an optical isolator 6 .

[0054] The material of disc 1 is Yb:YAG crystal with a diameter of 15mm and a thickness of 200um. The front of the disc is coated with high-transparency film and the back is coated with high-reflection film. 99.95%; the first plane reflector 2 and the second plane reflector 3 are both 1064nm high reflection mirrors, and the reflectivity is 99.99%; the electro-optic crystal 9 is a KDP type crystal; the polarization direction of the polarizer 8 is parallel to the paper surface.

[0055] When the voltage of the driving power supply 5 is 0, the polarization state does not change when the laser passes through the electro-opt...

Embodiment 3

[0057] Figure 4 Schematic diagram of the structure of the solid-state laser provided by Embodiment 3 of the present invention, such as Figure 4 As shown, it includes a disc 1 , a first plane mirror 2 , a second plane mirror 3 , a liquid crystal spatial light modulator 10 , a driving power supply 5 , a polarizer 8 , a polarizing beam splitter 7 , and an optical isolator 6 .

[0058] The material of disc 1 is Yb:YAG crystal with a diameter of 15mm and a thickness of 200um. The front of the disc is coated with high-transparency film and the back is coated with high-reflection film. 99.95%; the first plane mirror 2 and the second plane mirror 3 are both 1064nm high reflection mirrors, and the reflectivity is 99.99%; the polarization direction of the polarizer 8 is parallel to the paper surface. In the initial state of the liquid crystal spatial light modulator 10 , the long axis of the internal liquid crystal molecules is along the optical axis, and the driving power 5 is appli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com