Method for preparing sparassis crispa fermentation medium

The technology of a fermentation medium and Hydrangea, which is applied in the field of preparation of Hydrangea fermentation medium, can solve the problems of low biotransformation rate of culture substrate, unfavorable promotion and consumption of Hydrangea, and long hydrangea cultivation period, so as to reduce the cultivation cost, Effect of shortening the growth cycle and increasing individual weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

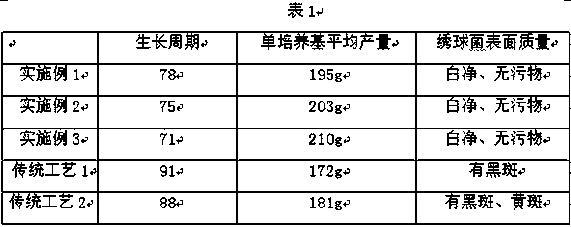

Embodiment 1

[0026] S1: The natural community environment in the Changbai Mountains in Northeast China is good, and the soil and decayed wood in the pine forest under the forest without human activities are selected. The soil and decayed wood are collected at a depth between the surface and 8 to 12 cm below the surface. Stones, stones, For fallen leaves and weeds, crush the rotten wood and mix it with the soil. After mixing, add normal saline to the soil. The weight ratio of soil and normal saline is 1:2. Add ammonium sulfate, brown sugar and glucose, the mass ratio of supernatant, ammonium sulfate and sugar source is 100:0.5:2, mix and cultivate to obtain culture medium;

[0027] S2: Mix 75 parts of pine wood chips, 10 parts of chaff, and 5 parts of flour in parts by weight to obtain a primary matrix;

[0028] S3: After diluting the culture solution by 50 times, spray it on the primary substrate, and stir while spraying, until the water content reaches 60%, cover the film and carry out st...

Embodiment 2

[0032] S1: The natural community environment in the Changbai Mountains in Northeast China is good, and the soil and decayed wood in the pine forest under the forest without human activities are selected. The soil and decayed wood are collected at a depth between the surface and 8 to 12 cm below the surface. Stones, stones, For fallen leaves and weeds, crush the rotten wood and mix it with the soil. After mixing, add normal saline to the soil. The weight ratio of soil and normal saline is 1:3. Add ammonium sulfate, brown sugar and glucose, the mass ratio of supernatant, ammonium sulfate and sugar source is 100:1:3.5, mix and cultivate to obtain culture medium;

[0033] S2: Mix 50 parts of pine wood chips, 15 parts of chaff and wheat bran, and 7 parts of flour in parts by weight to obtain a primary matrix;

[0034] S3: After diluting the culture solution by 75 times, spray it on the primary substrate, and stir while spraying, until the water content is 62%, cover the film and ca...

Embodiment 3

[0038] S1: The natural community environment in the Changbai Mountains in Northeast China is good, and the soil and decayed wood in the pine forest under the forest without human activities are selected. The soil and decayed wood are collected at a depth between the surface and 8 to 12 cm below the surface. Stones, stones, For fallen leaves and weeds, crush the rotten wood and mix it with the soil. After mixing, add normal saline to the soil. The weight ratio of soil and normal saline is 1:4. Add ammonium sulfate, brown sugar and glucose, the mass ratio of supernatant, ammonium sulfate and sugar source is 100: 1.5: 5, mix and cultivate to obtain culture medium;

[0039] S2: Mix 85 parts of pine wood chips, 20 parts of chaff and wheat bran, and 10 parts of flour in parts by weight to obtain a primary matrix;

[0040] S3: After diluting the culture solution by 100 times, spray it on the primary substrate, and stir it while spraying until the water content is 65%, then cover it w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com