Anionic oligomeric surfactant and preparation method thereof

A surfactant and anionic technology, applied in the field of anionic oligomeric surfactants and their preparation, can solve the problem that emulsifiers or additives cannot meet performance requirements, and achieve fine droplet particle size, high Zeta potential, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] In a second aspect, the present invention provides a method for preparing an anionic oligomeric surfactant, the method comprising: under alkali-catalyzed conditions, a mixed solvent formed of p-alkylphenol and glyoxylic acid in an organic solvent and water in a contact reaction, or

[0022] Under acid-catalyzed conditions, the para-alkylphenol and glyoxylic acid are contacted in a mixed solvent formed of an organic solvent and water, and then a base is added to the system to neutralize the acid catalyst and react with glyoxylic acid. Salt-forming reaction.

[0023] In the method of the present invention, those skilled in the art should understand that the contact reaction carried out under the condition of alkali catalysis comprises: under the catalysis of alkali catalyst, p-alkylphenol and glyoxylic acid are formed in organic solvent and water The phenolic condensation reaction that occurs by heating in a mixed solvent, and the salt-forming reaction between the base c...

Embodiment 1

[0041] This example is used to illustrate the anionic oligomeric surfactant of the present invention and its preparation method.

[0042] After mixing 206g p-tertoctylphenol and 126.8g glyoxylic acid aqueous solution (mass concentration is 50%) in 100g dioxane, add 10.3g p-toluenesulfonic acid as a catalyst, heat to reflux and react at 80°C 4h. Afterwards, 36.6 g of sodium hydroxide was added into the reaction system for reaction, and the solvent was evaporated after the reaction to obtain the product anionic oligomeric surfactant A1.

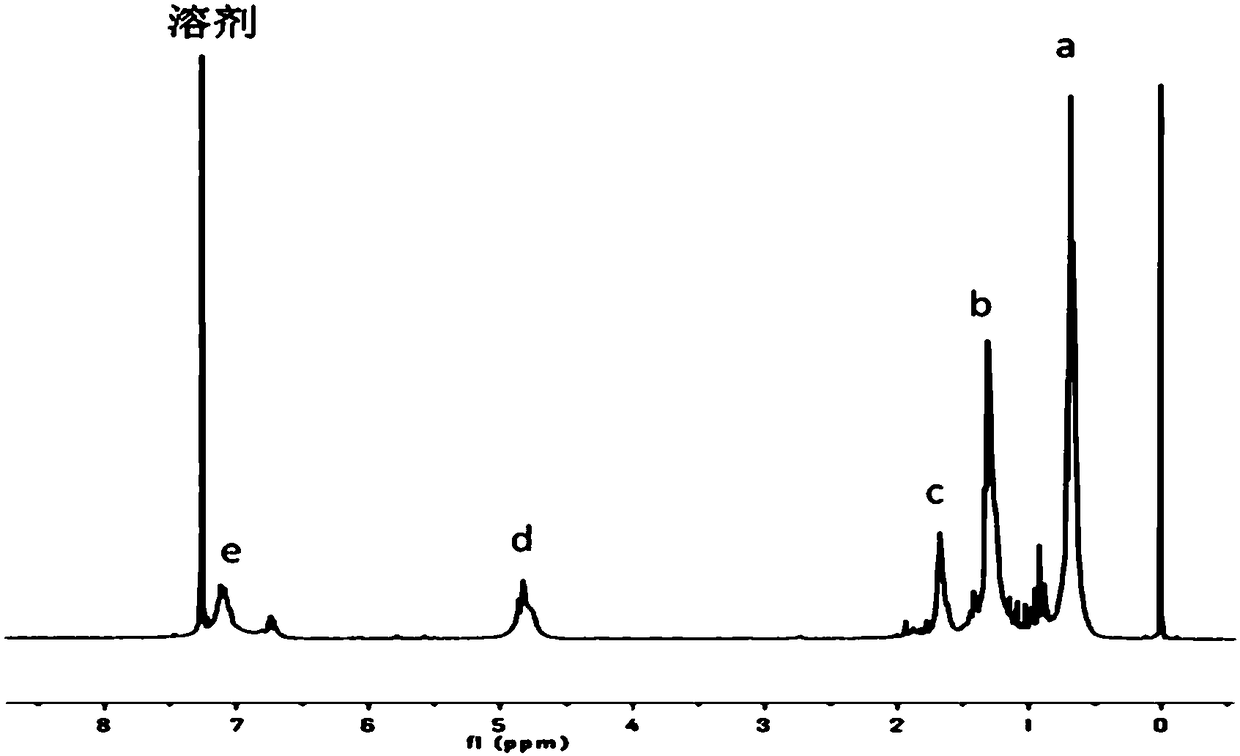

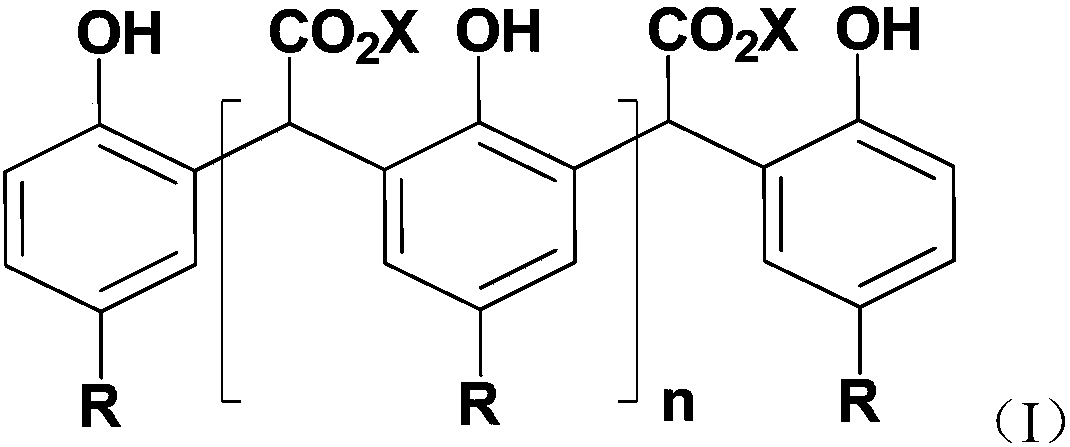

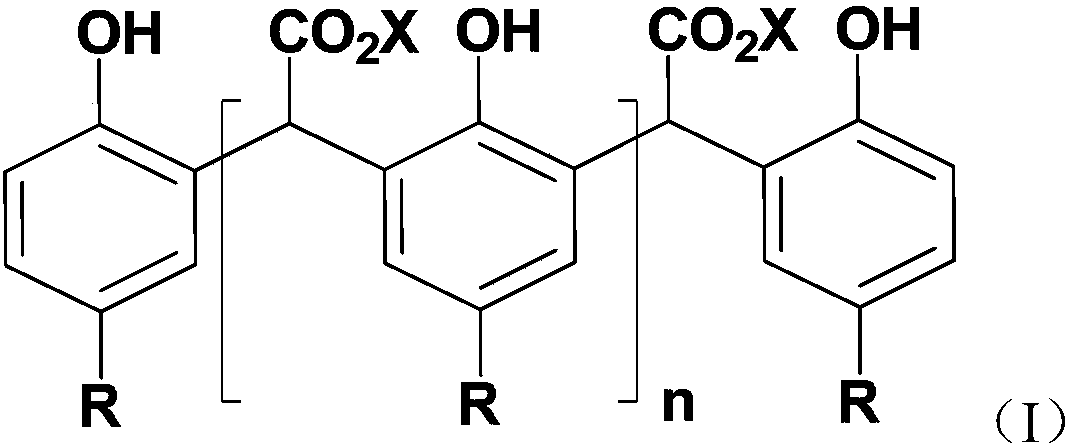

[0043] Carry out hydrogen spectrum analysis to anionic oligomeric surfactant A1, its hydrogen spectrum pattern is as follows figure 1 As shown, peaks a, b, and c correspond to a total of 9 protons of 3 methyl groups at the end of teroctyl, a total of 6 protons of 2 methyl groups at chemical equivalents, and a middle methylene group. 2 protons; the d peak corresponds to one proton of the carboxyl-ortho-methylene group formed after the phenolic...

Embodiment 2

[0047] This example is used to illustrate the anionic oligomeric surfactant of the present invention and its preparation method.

[0048] After mixing 220g of p-nonylphenol and 129.5g of glyoxylic acid aqueous solution (mass concentration: 50%) in 40g of tetrahydrofuran, add 176.8g of triethylamine as a catalyst, heat to reflux and react at 50°C for 8h, evaporate after the reaction solvent to obtain the product anionic oligomeric surfactant A2.

[0049] Anionic oligomeric surfactant A2 is carried out hydrogen spectrum analysis, after analysis, it can be known that the average structural formula of anionic oligomeric surfactant A2 is shown in the following formula (III):

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com