Scavenging agent used for transformer iron core insulating varnish, and scavenging method

A technology of transformer iron core and scavenger, which is applied in the direction of cleaning methods using liquids, chemical instruments and methods, cleaning methods and appliances, etc., which can solve problems such as polluting the environment, increasing the difficulty of recycling and smelting, and unfavorable properties of re-smelting materials. The preparation method is simple, the removal method is simple and easy, and the effect of being convenient for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050]In a preferred embodiment of the present invention, the preparation method of the scavenger comprises: mixing trichloroethane, hexane, tetrachloroethylene and chloroform in proportion to obtain the scavenger.

[0051] The preparation method of the scavenger described in the invention is simple, only needs to mix the components in proportion, and is suitable for large-scale production and industrial application.

[0052] The present invention also provides a method for removing insulating varnish from transformer iron cores, comprising the following steps:

[0053] The transformer iron core is soaked in the scavenger, and after soaking, the transformer iron core is cleaned and dried to obtain the transformer iron core from which the insulating varnish has been removed.

[0054] The removal method of the present invention can swell the insulating varnish on the surface of the iron core by the scavenger only through a simple soaking process, so as to make it pulverize and f...

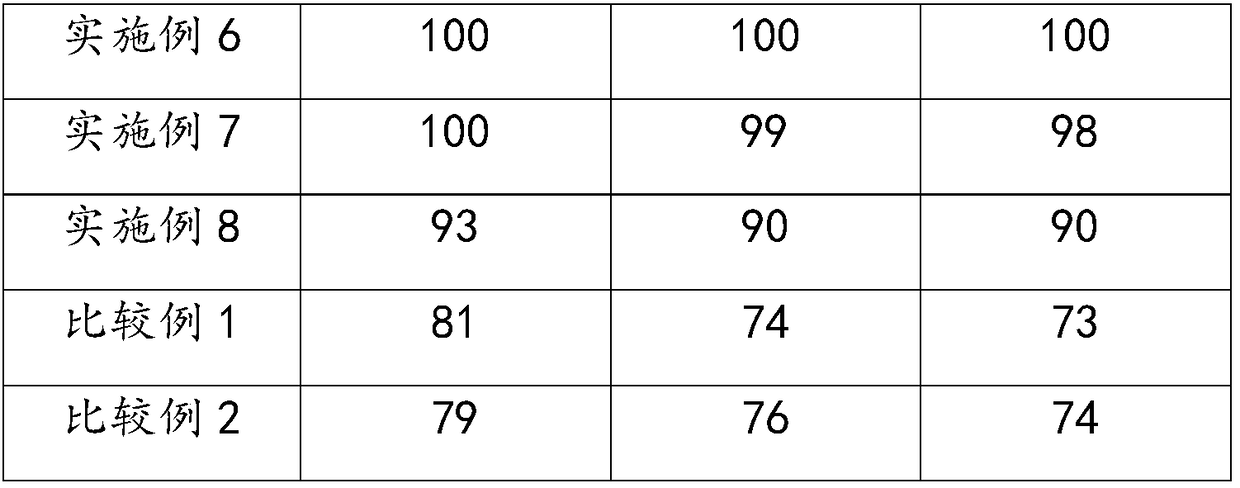

Embodiment 1

[0065] The scavenger for transformer iron core insulation varnish described in this embodiment is prepared by mixing 50% trichloroethane, 10% n-hexane, 10% tetrachlorethylene and 30% trichloromethane in volume fraction.

Embodiment 2

[0067] The scavenger for transformer iron core insulation varnish described in this embodiment is prepared by mixing 60% trichloroethane, 10% n-hexane, 15% tetrachlorethylene and 15% trichloromethane in volume fraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com