Wear-resisting high-temperature-resistant integrated type power station instrument ball valve

An integral, high-temperature-resistant technology, applied to valve details, valve devices, valve housing structures, etc., can solve problems such as valve body damage, material loss, and environmental pollution, so as to improve efficiency, reduce consumption, and improve overall performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

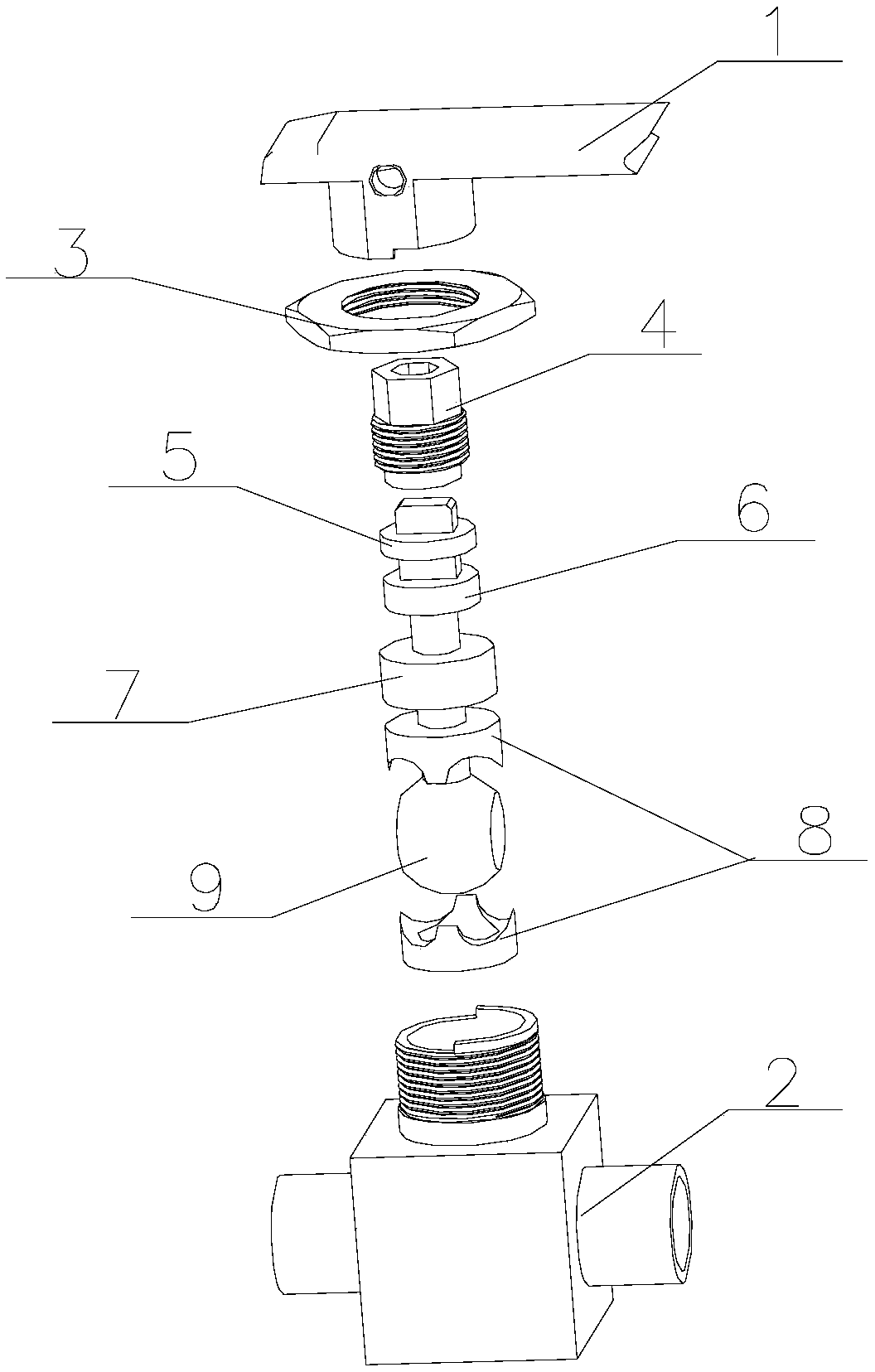

[0045] This embodiment provides a wear-resistant and high-temperature resistant integral power station instrument ball valve, the structure of which is as follows: figure 1 As shown, it includes handle 1, valve body 2, handle 1 is connected with lock nut 3, lock nut 3 is connected with pressure pad 5 through adjusting bolt 4, pressure pad 5 is connected with bush 6, bush 6 is connected with gland 7 Connection, the gland 7 is connected with the lining plate through the lining ring, the packing 8 and the connecting rod ball 9 are arranged between the gland 7 and the lining plate, the lining plate is connected with the valve body 2, and a protective layer is provided on the valve body 2, The protective layer includes the following components in parts by mass:

[0046] Black silicon carbide: 10 parts, fine-grained alumina: 7 parts, silicone modified epoxy resin: 40 parts, methylphenyl silicone resin: 20 parts, polyolefin elastomer: 5 parts, glass fiber: 20 parts, Modified vermicu...

Embodiment 2

[0060] This embodiment provides a wear-resistant and high-temperature resistant integral power station instrument ball valve, the structure of which is as follows: figure 1 As shown, it includes handle 1, valve body 2, handle 1 is connected with lock nut 3, lock nut 3 is connected with pressure pad 5 through adjusting bolt 4, pressure pad 5 is connected with bush 6, bush 6 is connected with gland 7 Connection, the gland 7 is connected with the lining plate through the lining ring, the packing 8 and the connecting rod ball 9 are arranged between the gland 7 and the lining plate, the lining plate is connected with the valve body 2, and a protective layer is provided on the valve body 2, The protective layer includes the following components in parts by mass:

[0061] Black silicon carbide 13 parts, fine-grained alumina: 9 parts, silicone modified epoxy resin: 50 parts, methylphenyl silicone resin: 30 parts, polyolefin elastomer: 9 parts, glass fiber: 30 parts, modified Vermicul...

Embodiment 3

[0076] This embodiment provides a wear-resistant and high-temperature resistant integral power station instrument ball valve, the structure of which is as follows: figure 1 As shown, it includes handle 1, valve body 2, handle 1 is connected with lock nut 3, lock nut 3 is connected with pressure pad 5 through adjusting bolt 4, pressure pad 5 is connected with bush 6, bush 6 is connected with gland 7 Connection, the gland 7 is connected with the lining plate through the lining ring, the packing 8 and the connecting rod ball 9 are arranged between the gland 7 and the lining plate, the lining plate is connected with the valve body 2, and a protective layer is provided on the valve body 2, The protective layer includes the following components in parts by mass:

[0077] Black silicon carbide: 12 parts, fine-grained alumina: 8 parts, silicone modified epoxy resin: 45 parts, methylphenyl silicone resin: 25 parts, polyolefin elastomer: 7 parts, glass fiber: 25 parts, Modified vermicu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com