Method of preparing biodiesel by catalyzing cottonseed oil with KOH-K2CO3-Al2O3 solid mixed base

A solid mixing and biodiesel technology, which is applied in chemical instruments and methods, biofuels, fat oil/fat refining, etc., can solve the problem of saponification reaction rate reducing conversion rate, transesterification reaction conversion rate is not ideal, and affects biodiesel conversion rate and other problems, to achieve the effect of improving performance, high reuse value, and excellent catalytic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preparation of KOH-K by impregnation method in the first part 2 CO 3 -Al 2 o 3 Solid mixed alkali catalyst and catalytic cottonseed oil preparation biological diesel research

[0038] 1 Instruments and reagents

[0039] 1.1 Cottonseed oil is food grade, purchased from Shihezi Development Zone Huashi Trading Co., Ltd.; nano-alumina is γ-Al 2 o 3 , analytically pure, purchased from Shandong West Asia Chemical Industry Co., Ltd. The rest of the reagents were commercially available analytically pure.

[0040] 1.2 Main test instruments

[0041]

[0042] 2 Experimental methods

[0043] 2.1 KOH-K 2 CO 3 -Al 2 o 3 Preparation of Solid Mixed Base Catalyst

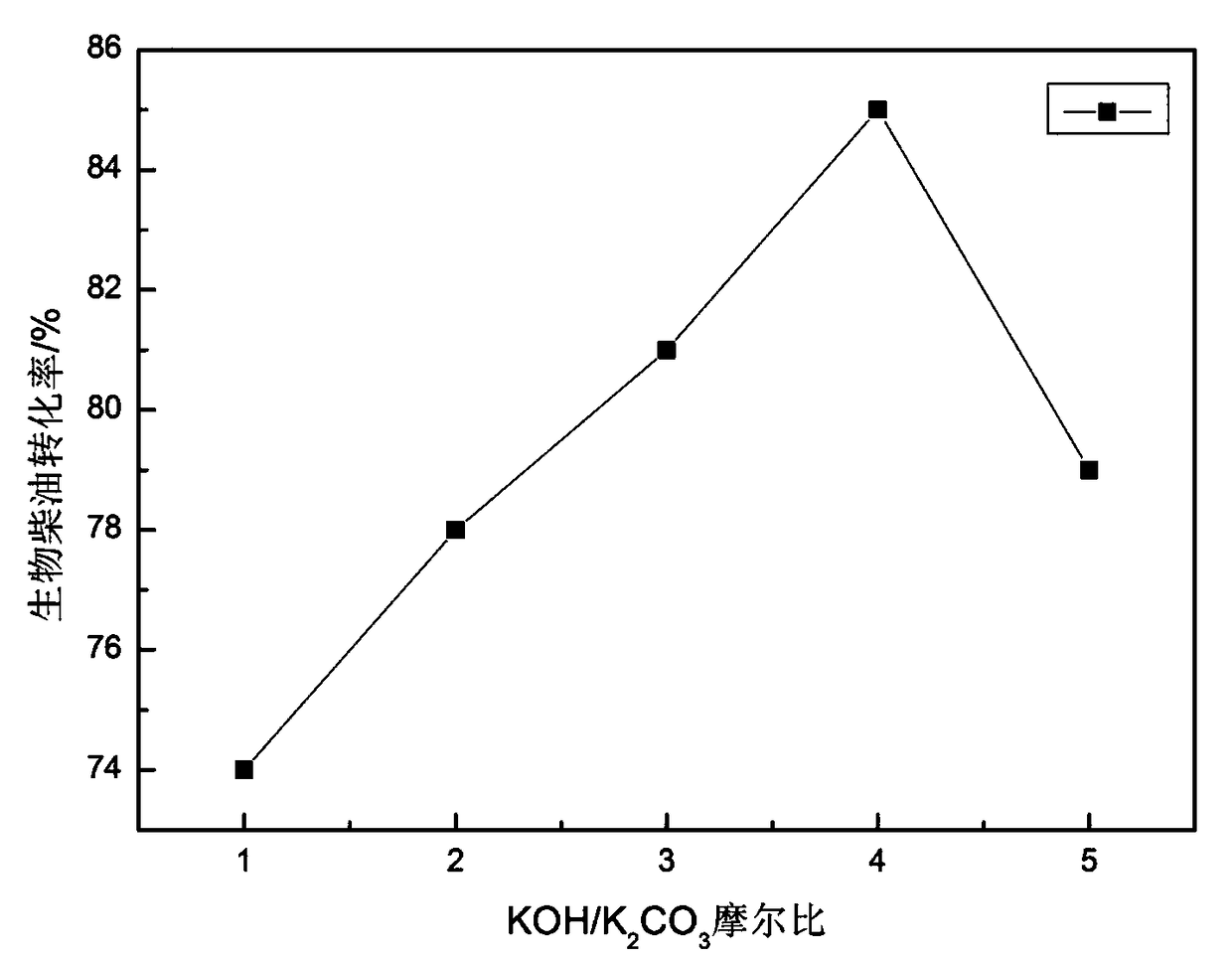

[0044] KOH-K 2 CO 3 -Al 2 o 3 The solid mixed alkali catalyst is prepared by an impregnation method. 0.05 mol of KOH and different amounts of K 2 CO 3 Placed in a 100mL beaker, the KOH and K 2 CO 3 The molar ratio of the substance is 1: (1-5), add 30mL of water to prepare an aqueous solution, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com