Device and method for non-destructive test of three-dimensional anisotropic thermal conductivity of materials

A three-dimensional, non-destructive testing technology, applied in the direction of material thermal development, etc., can solve the problems such as the non-destructiveness and convenience of the measurement technology, the large damage to the sample, the cumbersome measurement process, etc. Guarantee reusability and overcome the effect of low stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0030] The invention provides a non-destructive testing device and method for three-dimensional anisotropic thermal conductivity of materials.

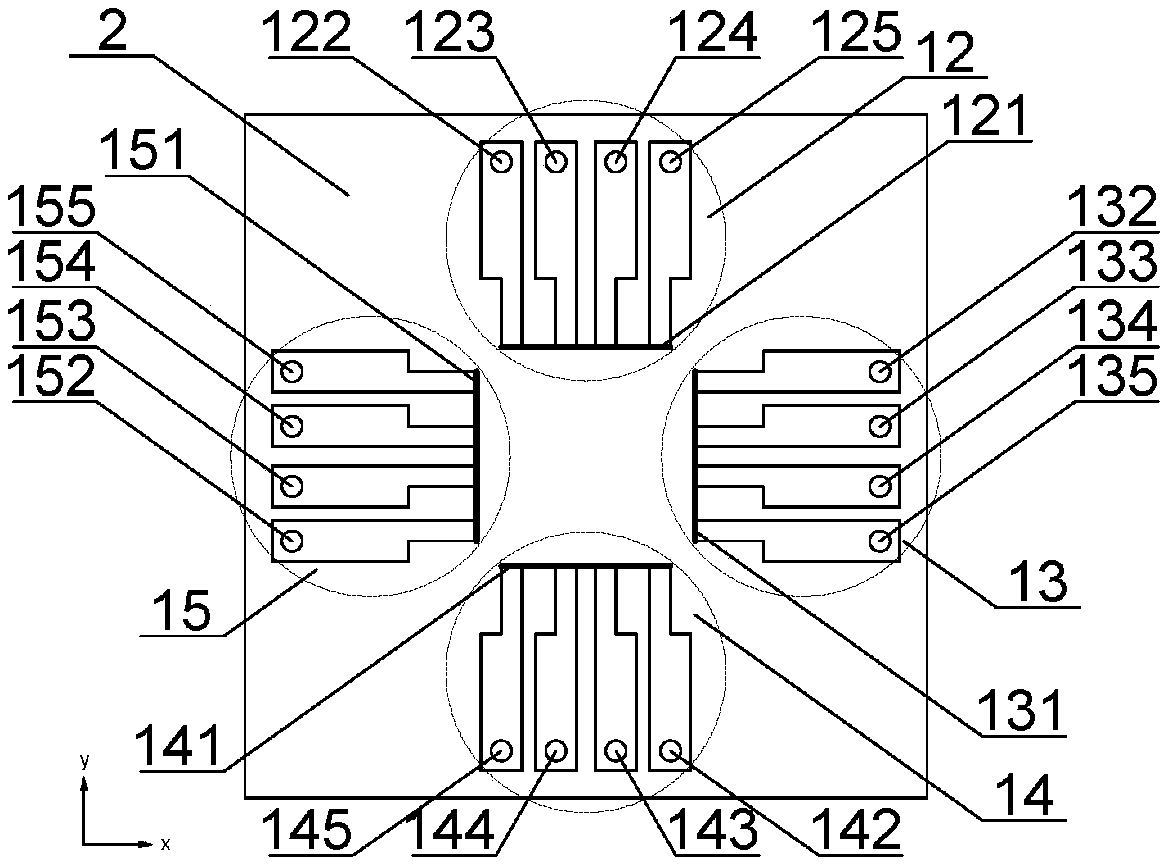

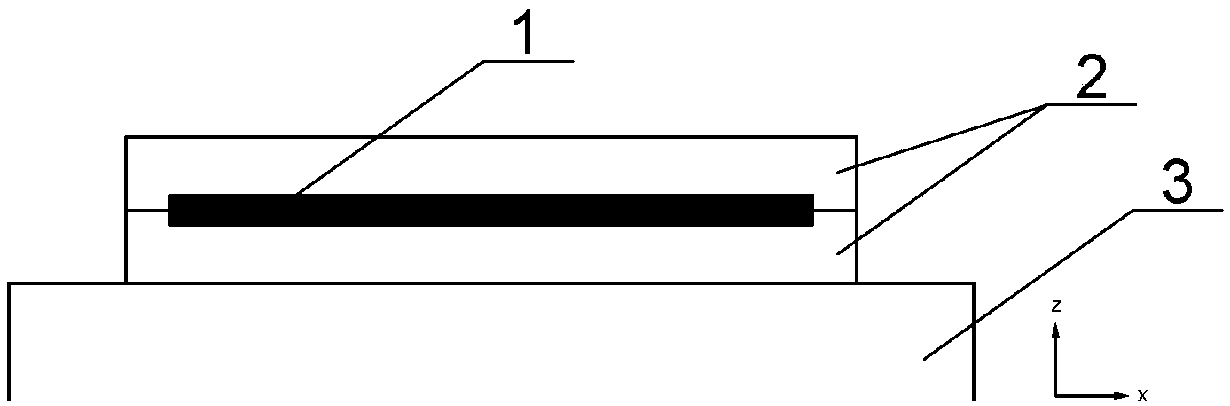

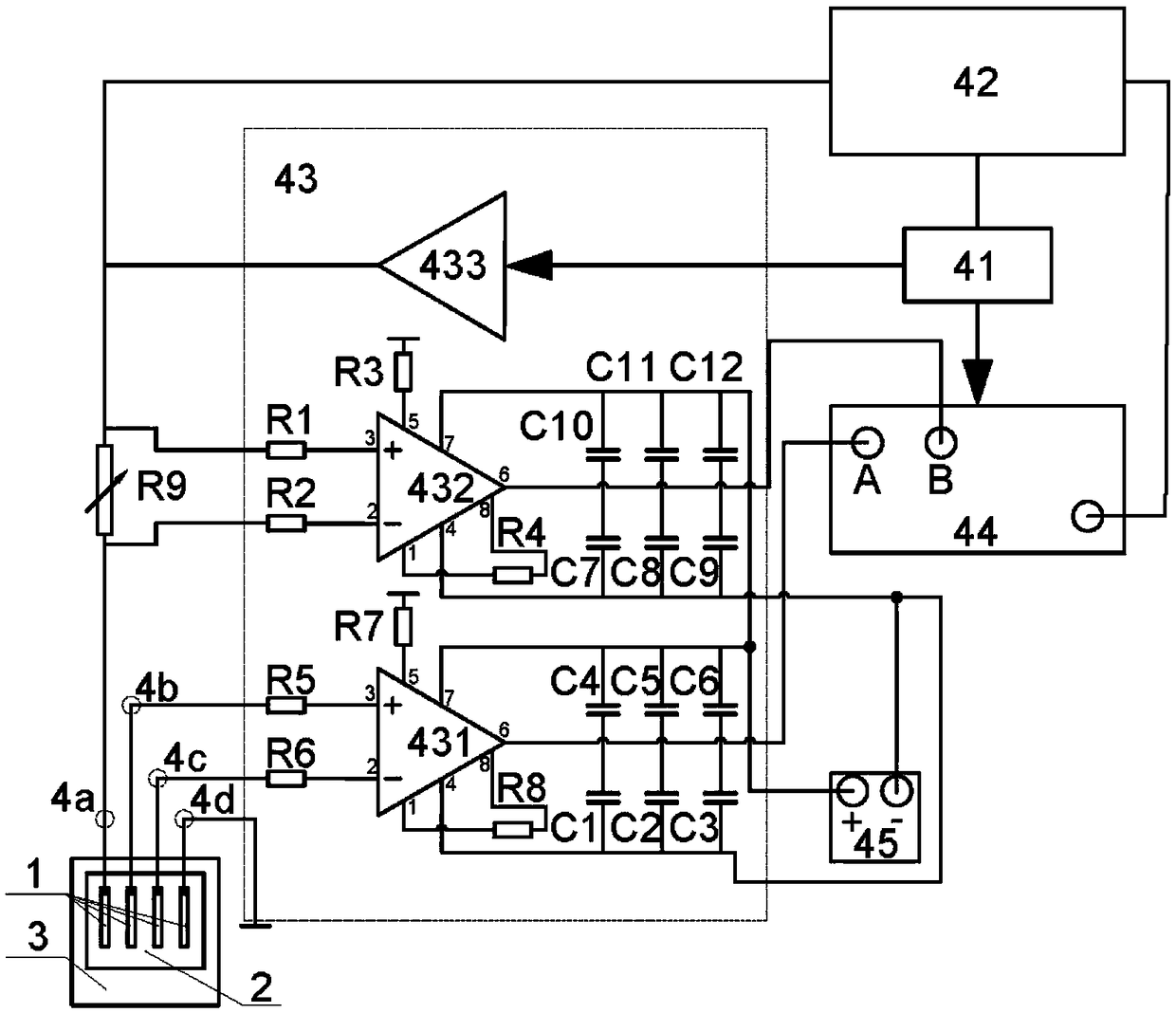

[0031] like image 3 As shown, the device includes a third harmonic method independent sensor and an electrical signal acquisition and processing module, wherein the third harmonic method independent sensor includes a linear heating detector module 1 and a wear-resistant insulating protective film 2; the electrical signal acquisition And processing module comprises signal generator 41, microcomputer control and data acquisition system 42, bridge module circuit 43, lock-in amplifier 44, high-precision DC power supply 45, adjustable resistance R9, current lead-in terminal and voltage lead-in terminal; Third harmon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com