A method for preparing fatty acid ester antiwear agent using solid superacid catalyst for esterification of acid type antiwear agent

A solid super acid, fatty acid ester technology, applied in the preparation of carboxylate, the preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve the problems of complex impurities, environmental pollution, dark color and other problems, and achieve low production costs , The effect of more recycling and high catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

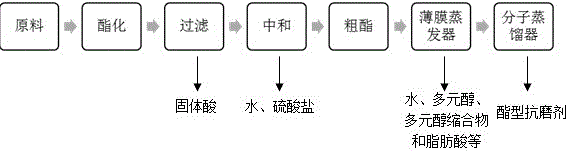

Image

Examples

Embodiment 1

[0025] A preparation method for a solid superacid catalyst for acid type antiwear agent esterification, the steps comprising:

[0026] (1) In a 500L container, put 9.5kg of titanium tetrachloride in the kettle, add 300kg of distilled water to dilute, and then add 10kg of calcined and pulverized alumina to fully impregnate it, wherein the molar ratio of Ti / Al is 0.5 :1;

[0027] (2) Add dropwise the dilute ammonia water precipitant with a mass concentration of 12 (wt)%, adjust the pH value at 8-9, fully stir and hydrolyze until the precipitation no longer increases;

[0028] (3) aging the precipitate together with the mother liquor at 0°C for 48 hours;

[0029](4) Filter after aging, and wash the precipitated AgNO with deionized water to 0.1mol / L 3 Titration detection until there is no chloride ion or no more than 200us / cm by conductivity measurement; dry the precipitate at 100°C for 6 hours, grind the dried precipitate into powder and sieve it through a 100-mesh sieve;

[0...

Embodiment 2

[0033] Catalyst prepared by embodiment 1 catalyzes the method for preparing fatty acid ester antiwear agent, and its steps comprise:

[0034] (1) Place commercially available 140kg unsaturated fatty acid and 140kg glycerin molar ratio 1:3 in the reaction kettle, add 0.28kg and account for 0.1(wt)% SO of the total mass of reactant 4 2- / TiO 2 -Al 2 o 3 / La 3+ Solid superacid catalyst, stir to mix evenly, heat to 150-180°C, mix and evacuate, depressurize to 3kPa, control the cooling water temperature in the reflux condenser, so that the water produced by esterification is vacuumed away, and the glycerin is condensed and refluxed ;

[0035] (2) After the end of the transesterification reaction, let stand or centrifuge to separate SO 4 2- / TiO 2 -Al 2 o 3 / La 3+ Solid superacid catalyst, SO 4 2- / TiO 2 -Al 2 o 3 / La 3+ The solid superacid catalyst is washed and dried for reuse next time;

[0036] (3) Add saturated sodium bicarbonate or a concentration of 2-5 (wt)...

Embodiment 3

[0040] Catalyst prepared by embodiment 1 catalyzes the method for preparing fatty acid ester antiwear agent, and its steps comprise:

[0041] (1) Place commercially available 140kg unsaturated fatty acid and 90kg glycerin molar ratio 1:2 in the reactor, add 4.6kg and account for 2(wt)% SO of the total mass of the reactant 4 2- / TiO 2 -Al 2 o 3 / La 3+ Solid super acid catalyst, stir to mix evenly, heat to 160-180°C, mix and evacuate, depressurize to 3kPa, control the cooling water temperature in the reflux condenser, so that the water produced by esterification is vacuumed away, and the glycerin is condensed and refluxed ;

[0042] (2) After the end of the transesterification reaction, let stand or centrifuge to separate SO 4 2- / TiO 2 -Al 2 o 3 / La 3+ Solid superacid catalyst, SO 4 2- / TiO 2 -Al 2 o 3 / La 3+ The solid superacid catalyst is washed and dried for reuse next time;

[0043] (3) Add saturated sodium bicarbonate or a concentration of 2-5 (wt)% sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com