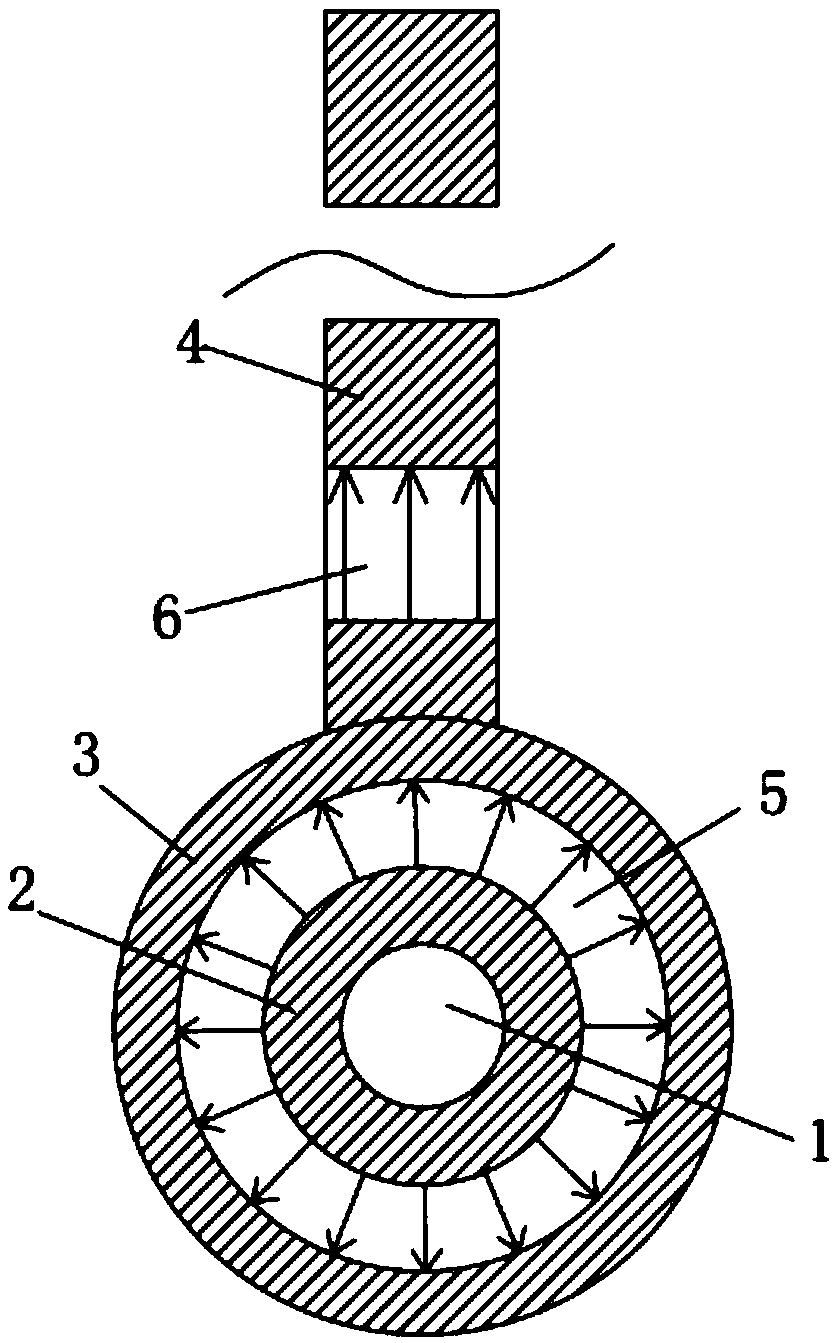

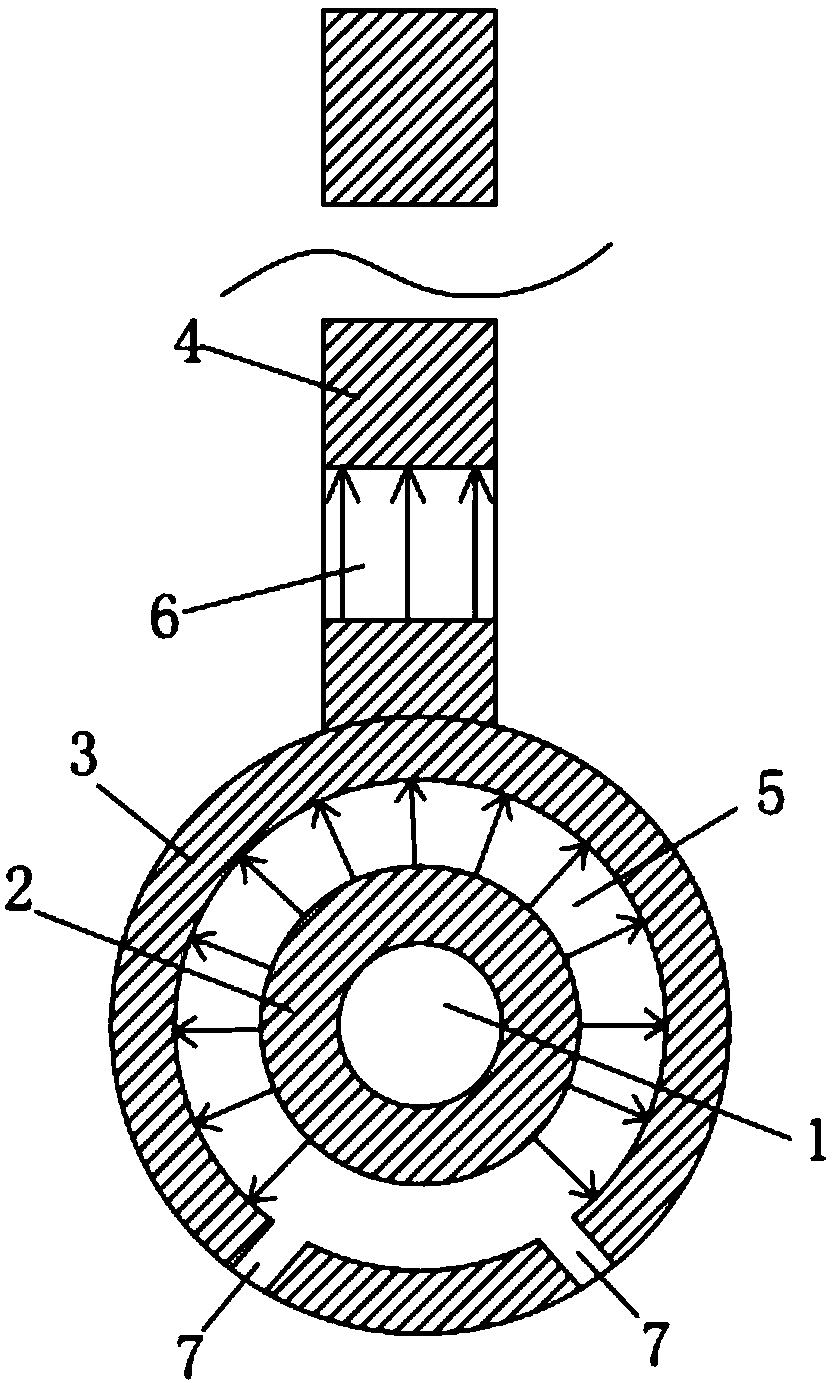

Method for accurately adjusting buried resistance based on via hole

A resistance value and accurate technology, applied in the direction of containing printed resistors, removing conductive materials and electrical components by light, etc., can solve the problems of unsatisfactory resistance value, change of buried resistance layer thickness, lateral erosion of dog teeth, etc. Improve resistance accuracy, reduce influence, and improve the effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a method for manufacturing a buried resistance circuit board, which includes a method for accurately adjusting the buried resistance value based on via holes. The specific process is as follows:

[0030] (1) Cutting: Cut out the nickel-phosphorus alloy buried resistance plate according to the panel size 520mm×620mm.

[0031] (2) Outer layer drilling: according to the drilling data, use mechanical drilling to drill holes on the nickel-phosphorus alloy buried resistance plate.

[0032] (3) Immersion Copper: A thin layer of copper is deposited on the hole wall by chemical reaction to provide the basis for the subsequent full-board electroplating. The backlight test is grade 10, and the thickness of the copper in the hole is 0.5 μm.

[0033] (4) Full board electroplating: According to the principle of electrochemical reaction, a layer of copper is electroplated on the basis of sinking copper to ensure that the thickness of the copper in the hole mee...

Embodiment 2

[0051] This embodiment provides a method for manufacturing a buried resistance circuit board, which includes a method for accurately adjusting the buried resistance value based on via holes. The specific process is as follows:

[0052] (1) Cutting: Cut out the core board according to the board size 520mm×620mm.

[0053] (2) Inner layer circuit production (negative film process): Inner layer graphics transfer, use a vertical coating machine to coat a photosensitive film on the core board, the film thickness of the photosensitive film is controlled at 8 μm, and a fully automatic exposure machine is used to 5-6 grids The exposure ruler (21-grid exposure ruler) completes the exposure of the inner layer circuit on the core board; the inner layer is etched, and the exposed and developed core board is etched out of the inner layer circuit, and the inner layer line width is measured as 3mil; the inner layer AOI, and then inspected Defects such as open and short circuits, line gaps, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com