Straw crushing and returning method by spraying livestock and poultry manure

A technology for livestock and poultry manure and straw, which is applied to the field of livestock and poultry manure spraying and returning straw powder to the field, can solve problems such as inability to use it, and achieve the effects of low cost, reducing non-point source pollution, and improving soil organic matter and nutrient content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

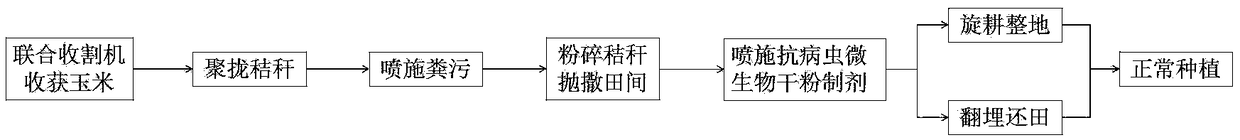

[0062] The method for returning livestock and poultry manure to fields by spraying straw powder, comprising the following steps:

[0063] 1. Coarse crushing of straw when harvesting corn

[0064] After the corn enters the mature stage, it is harvested with a corn combine harvester, and the corn stalks are crushed (length < 10 cm), and the height of the stubble is < 5 cm, and they are evenly scattered in the field.

[0065] 2. Gather straw

[0066] The corn stalks scattered in the 8 ridges were gathered in the middle 2 ridges by using the tractor towed finger-disc rake.

[0067] 3. Spraying manure and decomposing microbial preparations

[0068] The sewage suction truck absorbs the feces stored in the pig farm oxidation pond, and adds 0.1% (w / w) decomposing microbial preparations to the sewage suction truck. After mixing and stirring, the mixture is evenly sprayed on the straw surface, and the nitrogen application standard per hectare of cultivated land is 50kg.

[0069] 4. ...

Embodiment 2

[0082] The method for returning livestock and poultry manure to fields by spraying straw powder, is characterized in that it includes the following steps:

[0083] 1) While harvesting the corn with a corn combine harvester, crush the corn stalks to a length ≤ 10 cm, and evenly scatter them in the field;

[0084] 2) Gather the corn stalks scattered on the 8 ridges in the middle 2 ridges by using the tractor towed finger-disc rake;

[0085] 3) Take the livestock and poultry manure stored in the oxidation pond of the farm, add a decomposing microbial preparation to it at a ratio of 0.1% w / w, stir evenly, and then evenly spray the mixture on the straw surface;

[0086] 4) After the manure on the surface of the straw is naturally air-dried, crush it to a length of 2 to 5 cm, then evenly sprinkle the crushed product on the field, and spray the dry powder preparation of pest-resistant microorganisms on the field at the same time;

[0087] 5) Use a tractor with no less than 90 horsep...

Embodiment 3

[0098] The method for returning livestock and poultry manure to fields by spraying straw powder, is characterized in that it includes the following steps:

[0099] 1) While harvesting the corn with a corn combine harvester, crush the corn stalks to a length ≤ 10 cm, and evenly scatter them in the field;

[0100] 2) Gather the corn stalks scattered on the 8 ridges in the middle 2 ridges by using the tractor towed finger-disc rake;

[0101] 3) Take the livestock and poultry manure stored in the oxidation pond of the farm, add a decomposing microbial preparation to it at a ratio of 0.1% w / w, stir evenly, and then evenly spray the mixture on the straw surface;

[0102] 4) After the manure on the surface of the straw is naturally air-dried, crush it to a length of 2 to 5 cm, then evenly sprinkle the crushed product on the field, and spray the dry powder preparation of pest-resistant microorganisms on the field at the same time;

[0103] 5) Use a tractor with no less than 55 horsep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com