Antibacterial peptide composite material and preparation method and application thereof

A composite material and antimicrobial peptide technology, applied in the field of biomedicine, to achieve fast and efficient insertion and pore formation, low hemolytic toxicity, and good antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Preparation of Melittin / Graphene Oxide Nanodot Composite Materials by Chemical Modification

[0034] 1. Activate the amino group of melittin

[0035] Melittin was dissolved in PBS buffer to prepare a 2 mg / mL solution. Take 400 μL of this solution (containing 800 μg of melittin), dilute 75 mM TEPA 25 times and add 1 mL into the melittin solution, then add 10 μL of EDC with a concentration of 50 mM, and 10 μL of NHS with a concentration of 100 mM. Rotate and react at 250 rpm for 10 hours at 22°C. Solution A is obtained.

[0036] 2. Preparation of aqueous dispersion of graphene oxide nanodots

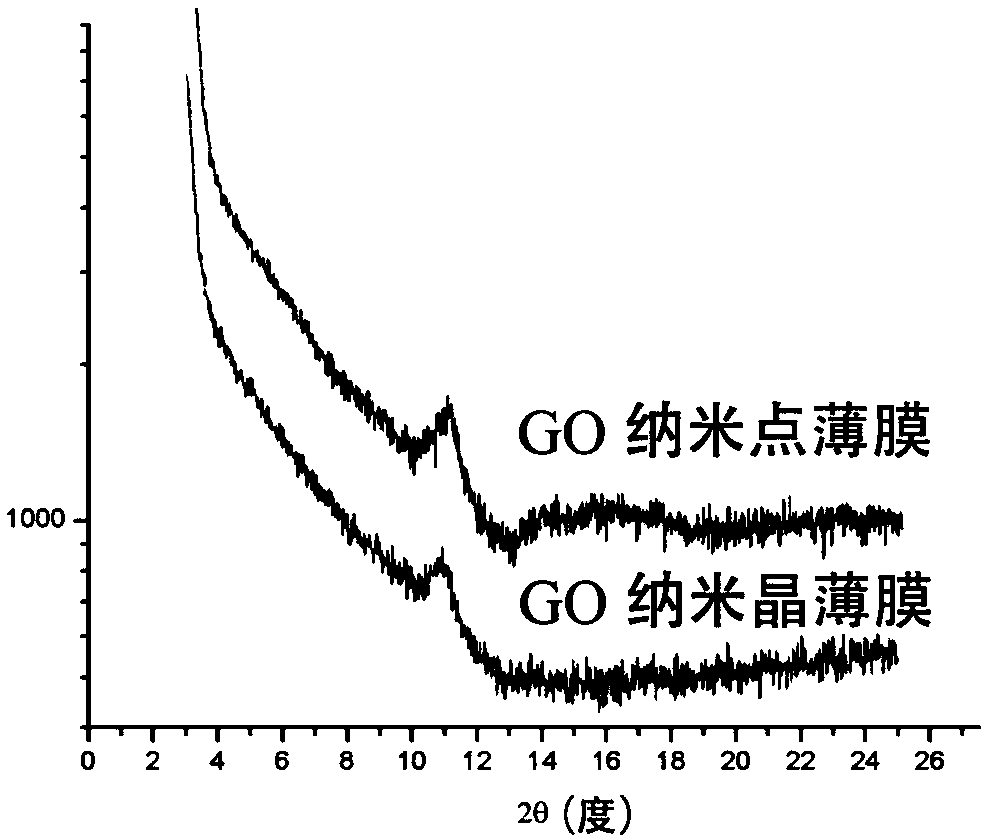

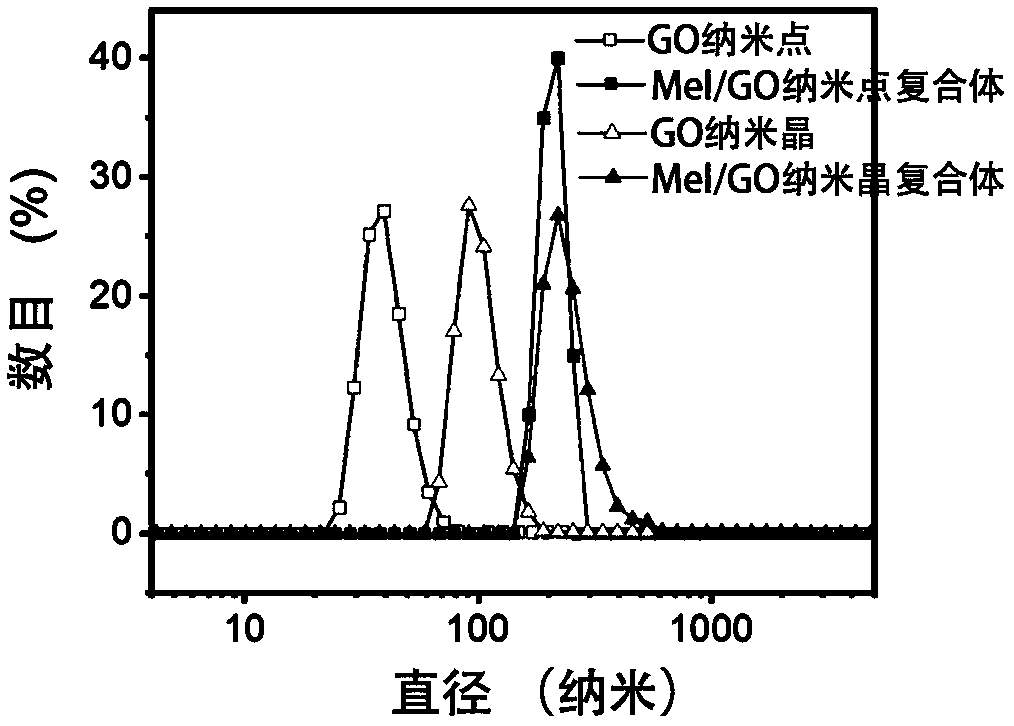

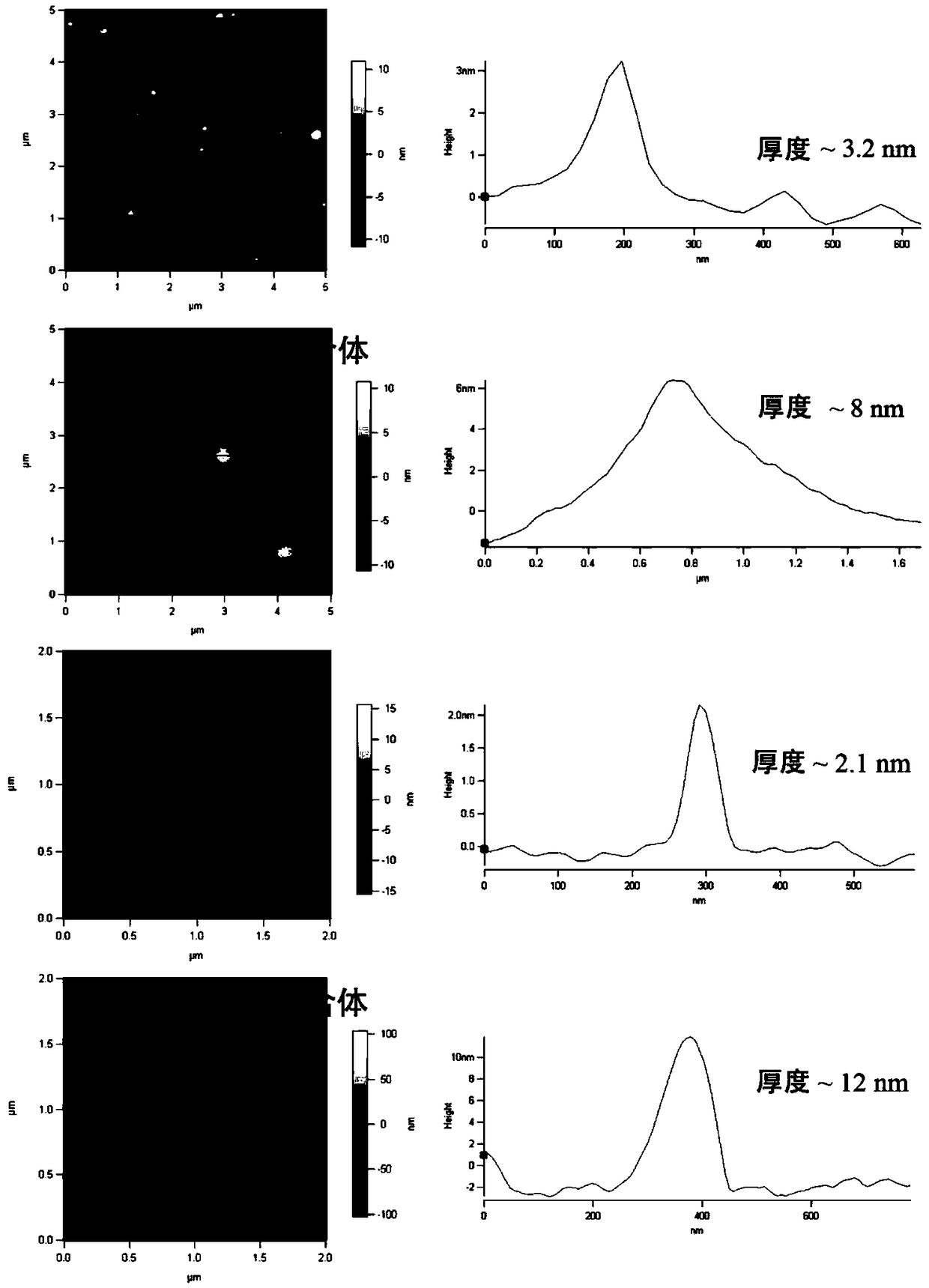

[0037] Disperse graphene oxide nanodots (GO NDs, size 39±10nm, about 4-5 layers of graphene oxide single layer) powder in water, prepare 0.5mg / mL aqueous dispersion, and ultrasonically for more than 2 hours to make it uniformly dispersed . Solution B is obtained.

[0038] 3. Chemical modification

[0039] Mix solution A with 200 μL of solution B, and continue to re...

Embodiment 2

[0040] Example 2: Preparation of melittin / graphene oxide nanocrystal composites by chemical modification

[0041] 1. Activate the amino group of melittin

[0042] Melittin was dissolved in PBS buffer to prepare a 2 mg / mL solution. Take 400 μL of this solution (containing 800 μg of melittin), dilute 75 mM TEPA 25 times and add 1 mL into the melittin solution, then add 10 μL of EDC with a concentration of 50 mM, and 10 μL of NHS with a concentration of 100 mM. Rotate and react at 250 rpm for 10 hours at 22°C. Solution A is obtained.

[0043] 2. Preparation of aqueous dispersion of graphene oxide nanocrystals

[0044] Disperse graphene oxide nanocrystal (GO NCs, size 90±10nm, containing about 2-3 layers of graphene oxide monolayer) powder in water to prepare a 0.5mg / mL aqueous dispersion, and ultrasonicate for more than 2 hours to make it uniformly dispersed . Solution B is obtained.

[0045] 3. Chemical modification

[0046]Mix solution A with 200 μL of solution B, and co...

Embodiment 3

[0047] Example 3: Preparation of melittin / graphene oxide nano-dot composite material by physical adsorption method

[0048] 1. Preparation of melittin solution

[0049] Dissolve melittin in PBS buffer to prepare solution A at 2 mg / mL.

[0050] 2. Preparation of aqueous dispersion of graphene oxide nanodots

[0051] Disperse graphene oxide nanodots (GO NDs, size 39±10nm, about 4-5 layers of graphene oxide single layer) powder in water, prepare 0.5mg / mL aqueous dispersion, and ultrasonically for more than 2 hours to make it uniformly dispersed . Solution B is obtained.

[0052] 3. Physical adsorption

[0053] Mix solution A with 200 μL of solution B, and continue to react on a shaker at 250 rpm for 2 h. The reacted liquid is freeze-dried to make an appropriate concentration according to the concentration requirements of melittin / GO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com