Rectification device for preparing electronic grade hydrogen fluoride

A hydrogen fluoride, electronic-grade technology, applied in hydrogen fluoride, fluorine/hydrogen fluoride, fractionation, etc., can solve problems such as increased difficulty and cost of processing, non-compliance with technical specifications, fluorine gas is highly toxic, etc., to achieve improved thermodynamic efficiency and low price , The effect of large liquid film mass transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

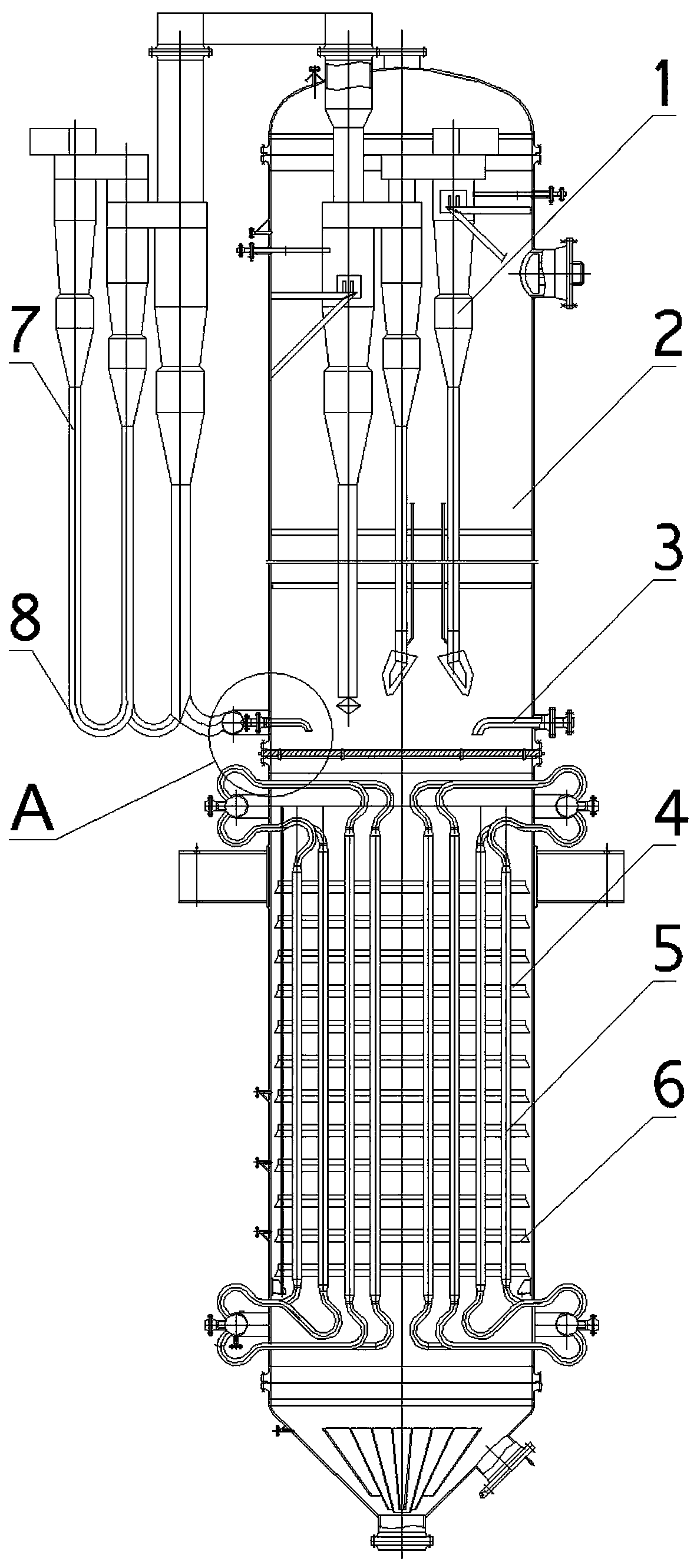

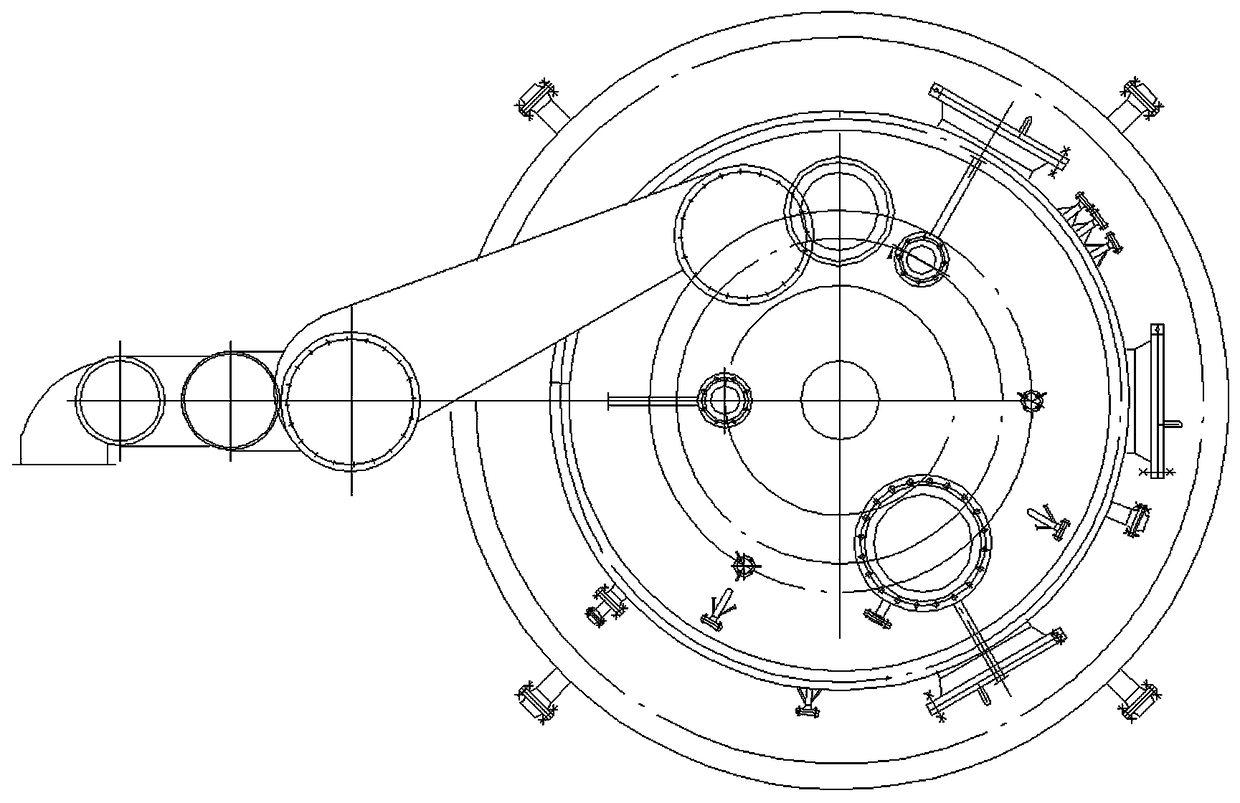

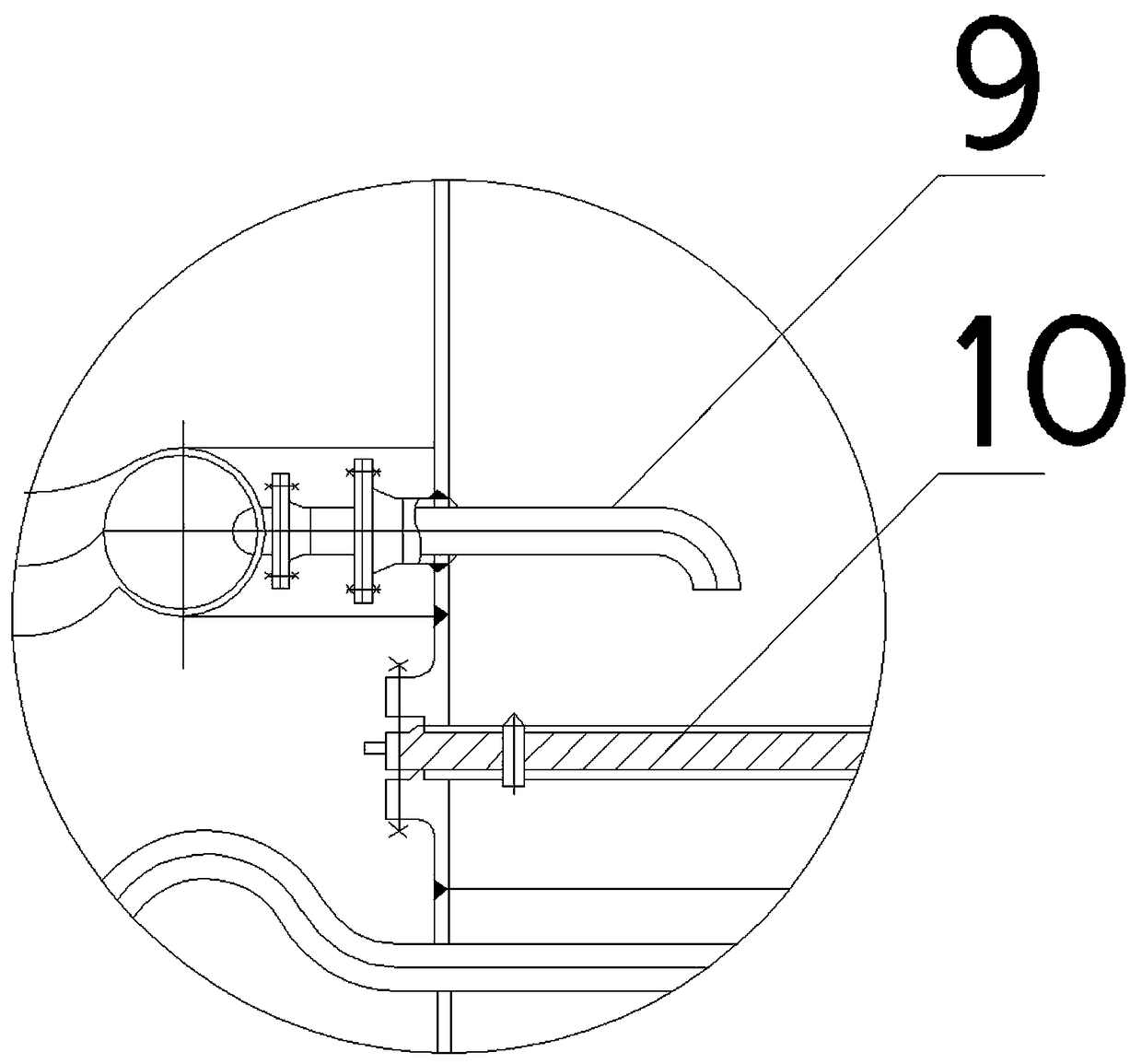

[0021] like figure 1 , figure 2 , image 3 As shown in the figure, an electronic-grade hydrogen fluoride rectification device is characterized by comprising: a multi-stage hydrocyclone separation condenser I1, a circulating fluidized bed distillation column 2, a feed liquid inlet 3, a constant temperature reboiler 4, a multi-stage hydrocyclone Liquid separation condenser II7, U-shaped liquid seal assembly 8, return pipe 9, and liquid distribution pan 10.

[0022] The circulating fluidized bed distillation tower body 2 is divided into upper and lower sections, the upper part is the rectification section, the lower part is the stripping section, and the rectification section is designed with a multi-stage hydrocyclone condenser I1 and a multi-stage hydrocyclone condenser II7 , the stripping section is designed with a constant temperature reboil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com