A method for removing carbon dioxide from industrial gases by pressure swing adsorption

An industrial gas, pressure swing adsorption technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of high investment costs and operating costs, achieve strong versatility, reduce investment and operating costs, and reduce investment costs and the effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

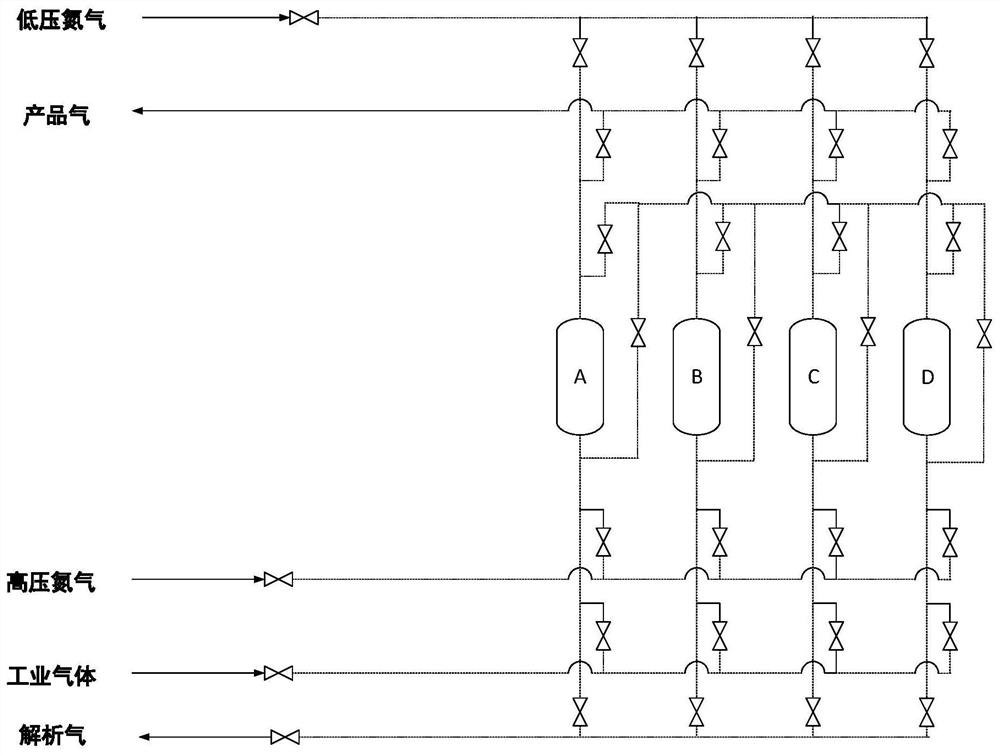

Image

Examples

Embodiment 1

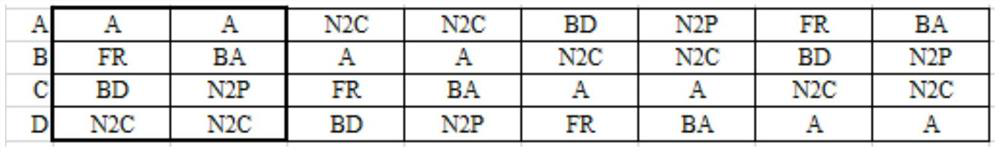

[0028] The pressure swing adsorption device used in Example 1 is a system consisting of four adsorption towers, and the time sequence of one cycle of the system is shown in Table 1.

[0029] Table 1 Cycle time sequence of four-tower pressure swing adsorption process for removing carbon dioxide

[0030]

[0031] As shown in Table 1, in each period of the adsorption regeneration cycle process, each tower of the system is in a different working state. For example, in a period of time shown in the thick line box in Table 1, the working status of each tower is:

[0032] Tower A is in the adsorption step. The industrial gas with a pressure of 1.2MPa (gauge pressure) enters the tower from the bottom of the tower for adsorption. The impurities in the industrial gas are trapped in the adsorption bed by the adsorbent, and the qualified product gas is drawn out from the top of the tower. Tower C is in the reverse discharge step for the first half of the time, and then enters the low-p...

Embodiment 2

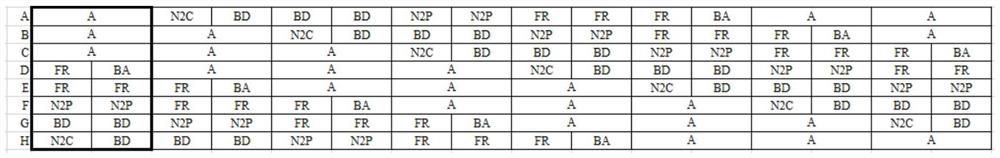

[0034] The pressure swing adsorption device used in Example 2 is a system consisting of eight adsorption towers, and the time sequence of one cycle of the system is shown in Table 2.

[0035] Table 2 The cycle sequence of the eight-column pressure swing adsorption process for carbon dioxide removal

[0036]

[0037] In each period of the adsorption regeneration cycle process, the towers of the system are in different working states. For example, in a period shown in the thick line box in Table 2, the working conditions of each tower are:

[0038] Tower A, Tower B, and Tower C are in the adsorption step. The industrial gas with a pressure of 1.2MPa (gauge pressure) enters the tower from the bottom of the tower for adsorption. The impurities in the industrial gas are trapped in the adsorption bed by the adsorbent. The qualified product The gas is drawn from the top of the tower. The first half of the H tower is in the high-pressure nitrogen replacement step. The high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com