Hydrogen recycle system and hydrogen recycle method

A technology of hydrogen recovery system and recovery device, which is applied in the field of hydrogen recovery, can solve the problems of poor energy efficiency and low hydrogen production rate, and achieve the effects of reducing waste gas volume, improving hydrogen recovery rate, and simple configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

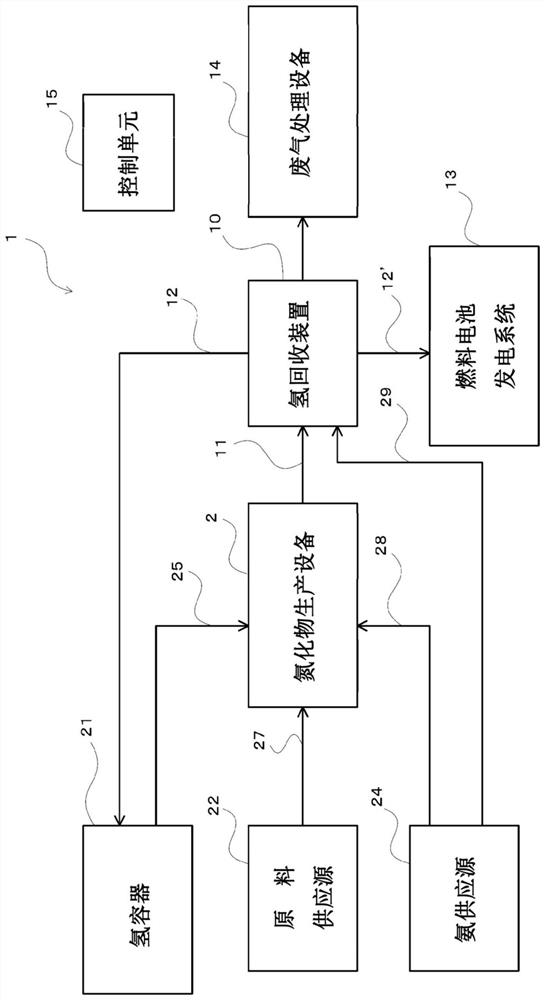

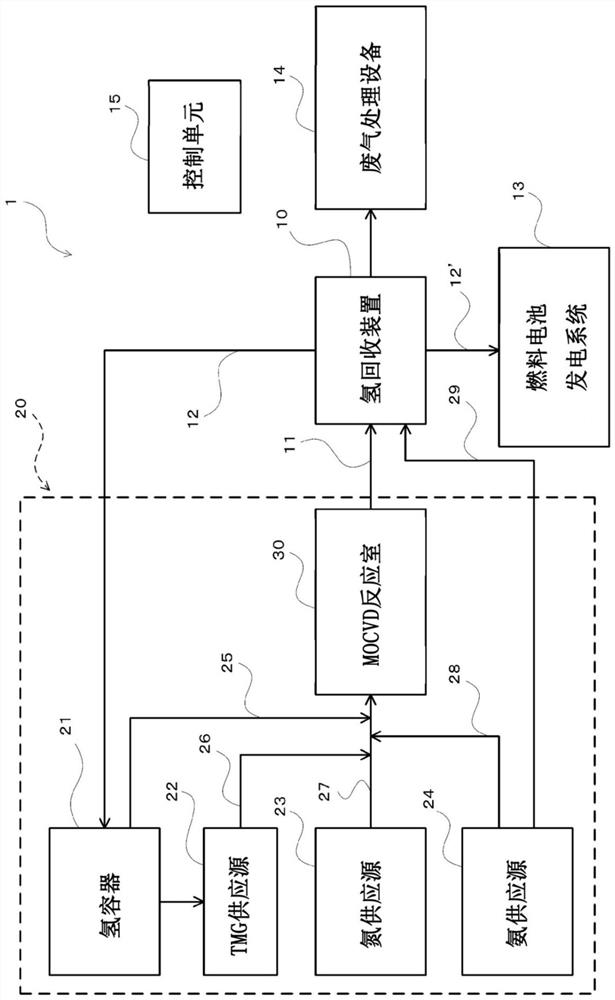

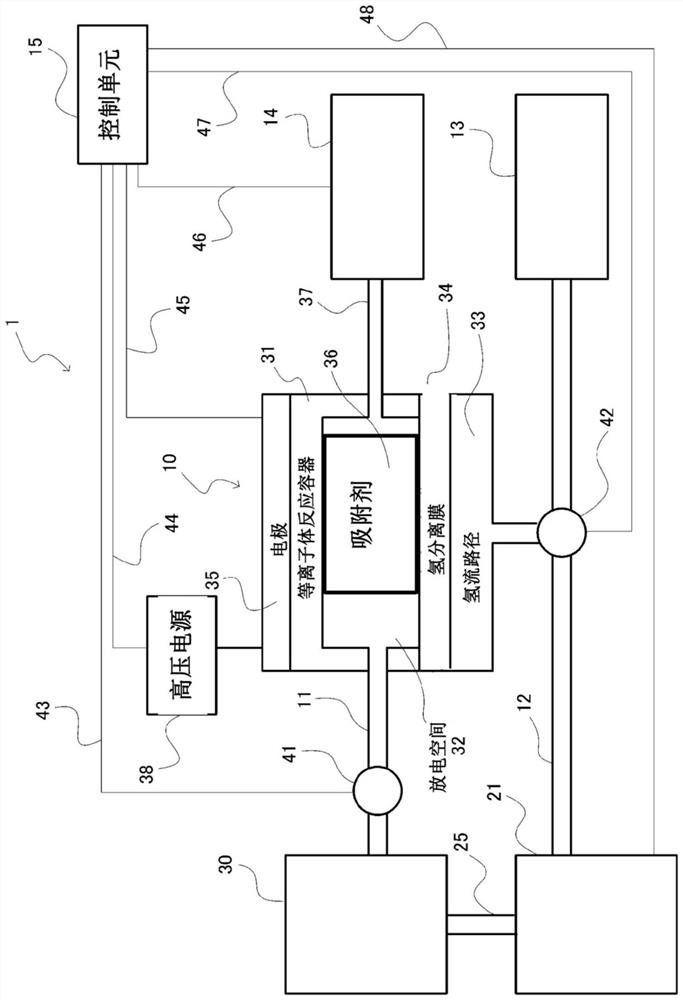

[0031] figure 1 A block diagram showing a configuration of a hydrogen recovery system 1 and a nitride production facility 2 that supplies exhaust gas to the hydrogen recovery system 1 according to an embodiment of the present invention. figure 2 A block diagram showing a configuration of a metal organic compound chemical vapor deposition apparatus 20 (hereinafter referred to as MOCVD apparatus 20 ) as an embodiment of a nitride production apparatus, and a hydrogen recovery system 1 that recovers off gas of the MOCVD apparatus. image 3 A block diagram schematically shows the hydrogen recovery device 10 of the hydrogen recovery system 1 and other equipment connected to the hydrogen recovery device 10 . The hydrogen recovery system 1 includes an exhaust gas supply path 11 that receives exhaust gas, a hydrogen recovery device 10 that purifies high-purity hydrogen from the exhaust gas, and a hydrogen supply path 12 that supplies the purified high-purity hydrogen. The hydrogen re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com