Preparation method of a high-purity quartz glass raw material

A quartz glass and raw material technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of not being able to use high-purity quartz glass raw materials, low SiO2 content, etc., achieve low production costs, reduce Al2O3 content, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

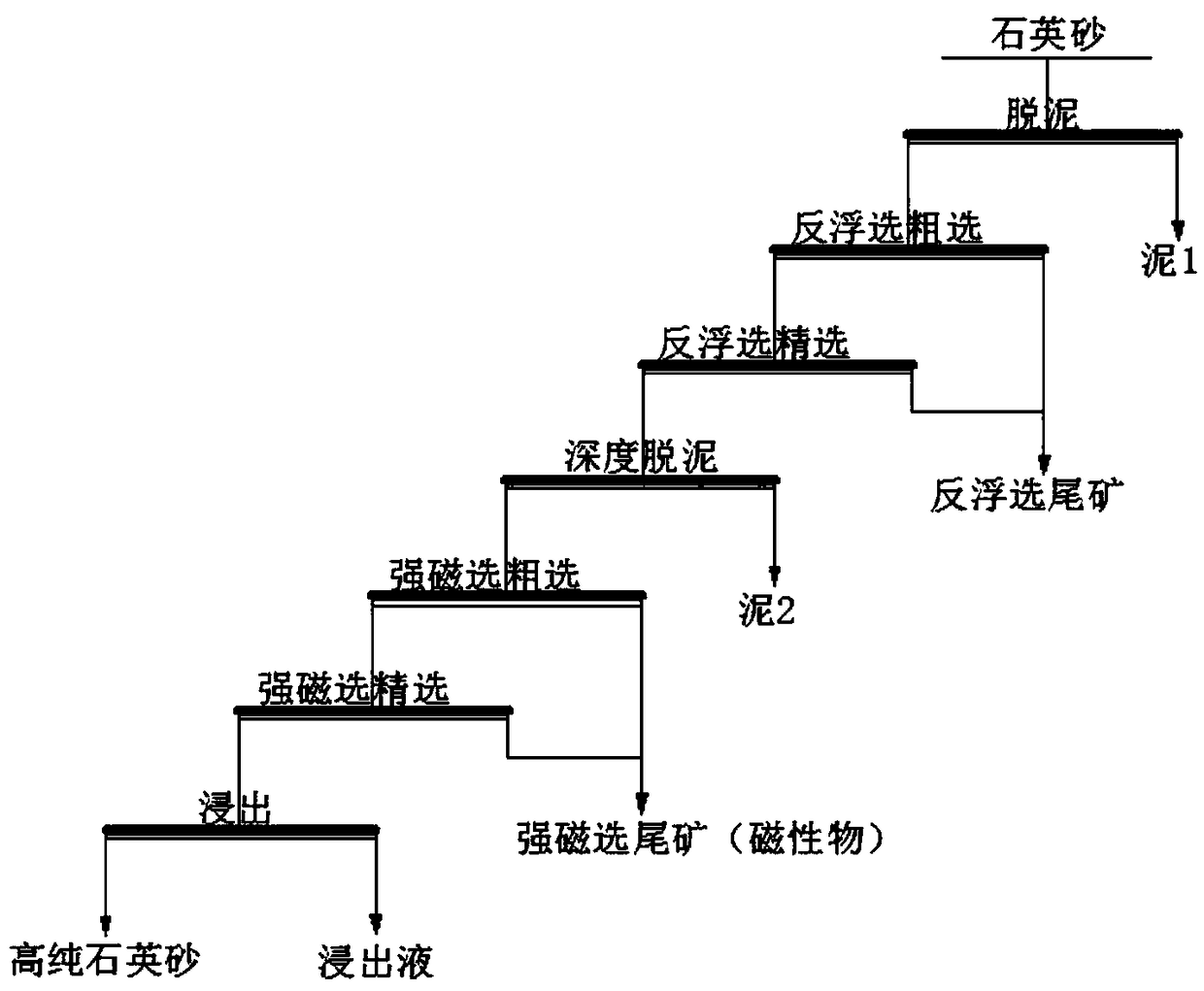

[0035] A certain quartz sand SiO 2 Grade 99.1942%, Al 2 o 3 Content 0.5242%, Fe 2 o 3 content of 0.1388%, first desliming the quartz sand less than 0.3mm, the desliming amount is 16.37wt%, and the bottom flow is the deslimed sand; then the deslimed sand is fed into the flotation machine for reverse flotation, and the reverse flotation process is a rough selection 1. One-time selection, the dosage of rough selection pH regulator sulfuric acid is 1000g / t, the dosage of dispersant sodium hexametaphosphate is 1500g / t, and the collector is a combination of sodium oleate and dodecylamine, which are added separately, and the dosage is 5000g / t respectively , 800g / t, the amount of selected dodecylamine is 400g / t, and the bottom of the tank is flotation concentrate; then the flotation concentrate is subjected to deep desliming, the desliming amount is 5.12wt%, and the coarse-grained grade is deslimed concentrate ore; then the deslimed concentrate is fed into the strong magnetic sepa...

Embodiment 2

[0038] A certain quartz sand SiO 2 Grade 98.7701%, Al 2 o 3 Content 0.4983%, Fe 2 o 3 content of 0.2720%, desliming the quartz sand less than 0.3mm, the desliming amount is 10.00wt%, and the bottom flow is the deslimed sand; then the deslimed sand is fed into the flotation machine for reverse flotation, and the reverse flotation process is a rough selection 1. One-time selection, the dosage of rough selection pH regulator sulfuric acid is 1000g / t, the dosage of dispersant sodium hexametaphosphate is 1500g / t, and the collector is a combination of sodium oleate and dodecylamine, which are added separately, and the dosage is 5000g / t respectively , 800g / t, the amount of selected dodecylamine is 400g / t, the bottom of the tank is flotation concentrate; then the flotation concentrate is deslimed in depth, the desliming amount is 5.00wt%, and the coarse-grained grade is desliming concentrate ore; then the deslimed concentrate is fed into the strong magnetic separator for magnetic ...

Embodiment 3

[0041] A certain quartz sand SiO 2 Grade 98.4813%, Al 2 o 3 Content 0.6897%, Fe 2 o 3 content of 0.3948%, desliming the quartz sand less than 0.3mm first, the desliming amount is 20.00wt%, and the bottom flow is deslimed sand; then the deslimed sand is fed into the flotation machine for reverse flotation, and the reverse flotation process is a rough selection 1. One-time selection, the dosage of rough selection pH regulator sulfuric acid is 1000g / t, the dosage of dispersant sodium hexametaphosphate is 1500g / t, and the collector is a combination of sodium oleate and dodecylamine, which are added separately, and the dosage is 5000g / t respectively , 800g / t, the amount of selected dodecylamine is 400g / t, and the bottom of the tank is flotation concentrate; then the flotation concentrate is deslimed deeply, the desliming amount is 10.00wt%, and the coarse-grained grade is deslimed concentrate ore; then the deslimed concentrate is fed into the strong magnetic separator for magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com