A kind of multi-station casting machine and casting method

A casting machine and multi-station technology, which is applied in the field of low-pressure casting, can solve the problems of low utilization rate of multi-station casting machines, achieve the effects of making full use of space, reducing power consumption, and saving site resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

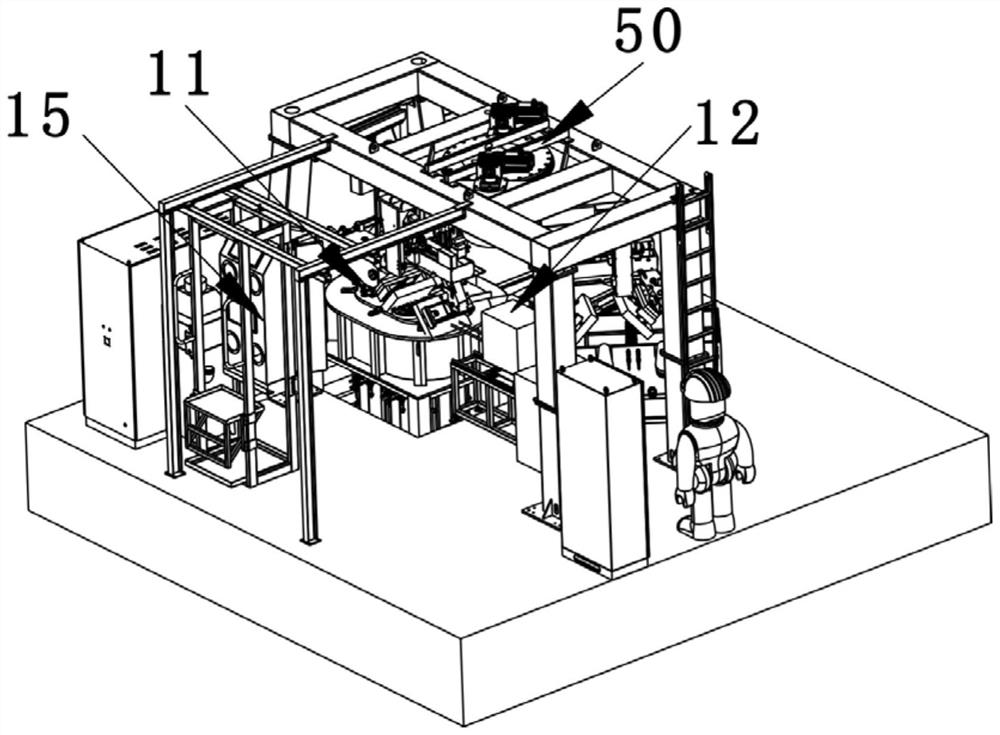

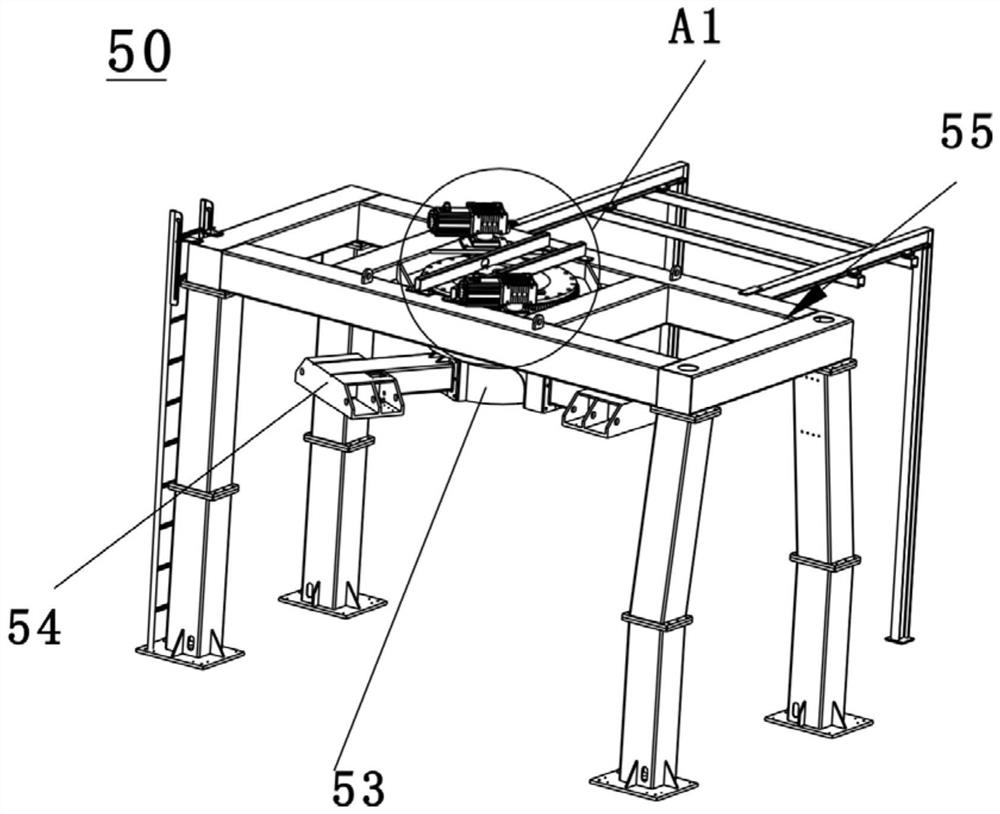

[0050] Please refer to Figure 1 to Figure 7 . A high-efficiency multi-station casting machine, comprising: a first station 11 for filling an injection mold with sand cores, a second station 12 for injecting a hot-melt material into the injection mold, and a second station 12 for placing a The third station 13 for forming the casting, the fourth station 14 for soaking the mould, and the robot 20 .

[0051] The manipulator 20 can drive the injection mold to pass through the first station 11, the second station 12, the third station 13 and the fourth station 14 in sequence, and control the corresponding action of the injection mold when the injection mold moves to the corresponding station. Complete the appropriate casting steps. For example, the manipulator 20 cooperates with the first station 11 to perform the sand core placing operation, the manipulator 20 automatically completes the mold clamping operation, cooperates with the second station 12 to complete the mold filling...

Embodiment 2

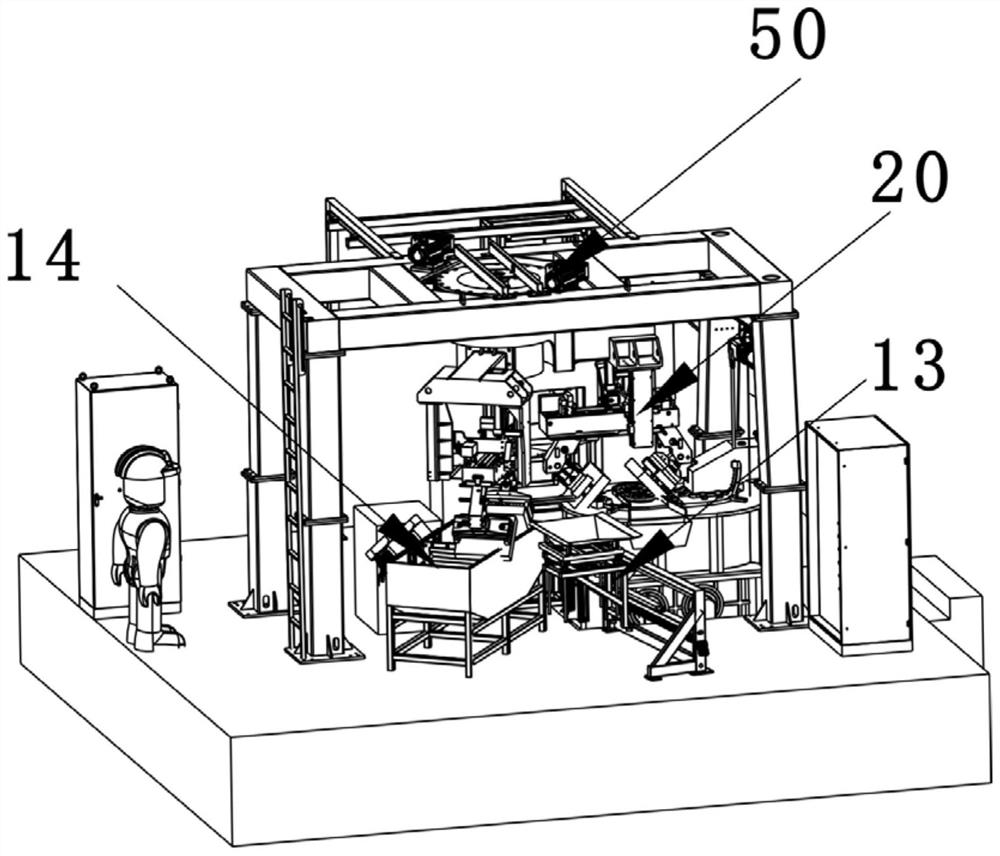

[0077] Please refer to Figure 8 to Figure 9 . The realization principle and the technical effect of the device provided by the embodiment of the present invention are basically the same as those in the first embodiment.

[0078] In this embodiment, the first station 11 , the second station 12 , the third station 13 and the fourth station 14 are evenly arranged around the axis of the rotating disk 51 , the number of the manipulators 20 is three, in the initial state, they correspond to the first station 11, the third station 13, and the fourth station 14 respectively, and each time the rotating mechanism 50 rotates, the three Each of the manipulators 20 respectively corresponds to one of the above-mentioned stations.

[0079] Therefore, the difference from Example 1 is that Example 1 can produce 4 shaped castings per production cycle, and this embodiment can produce 3 castings per cycle.

[0080] In this embodiment, the fourth station 14 includes: a graphite tank body 61 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com