Sound absorption and noise reduction decorative board and preparation method and application thereof

A decorative panel and noise reduction technology, applied in the field of composite panels, can solve the problems of overshooting and low noise outside the vehicle, and achieve the effect of excellent anti-icing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

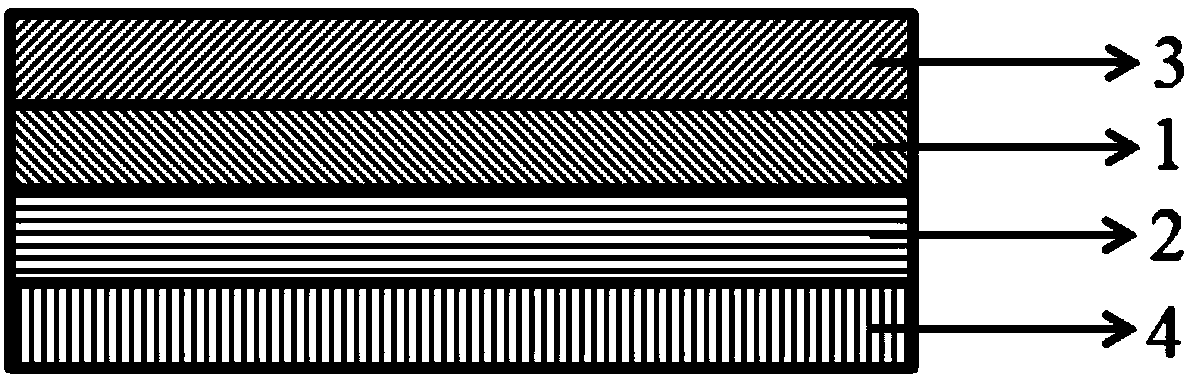

[0069] figure 1 The structural schematic diagram of the sound-absorbing and noise-reducing decorative board provided for this embodiment, from top to bottom is the first non-woven PET fiber layer (3), non-woven needle-punched glass fiber reinforced polypropylene layer (1), thermoplastic film layer ( 2) and a second non-woven PET fiber layer (4).

[0070] Wherein, the thickness of the first non-woven PET fiber layer is 0.5mm, and the grammage is 100g / m 2 ;

[0071] The non-woven needle-punched glass fiber reinforced polypropylene layer has a thickness of 6mm and a weight of 1000g / m 2 , based on the total mass of glass fiber reinforced polypropylene as 100%, the mass percentage of glass fiber is 50%;

[0072] The thickness of the thermoplastic film layer is 0.07mm and the weight is 50g / m 2 , the thermoplastic film layer is provided with a plurality of through holes, the aperture is 0.05mm, and the porosity is 7%. The raw materials for the preparation of the thermoplastic fil...

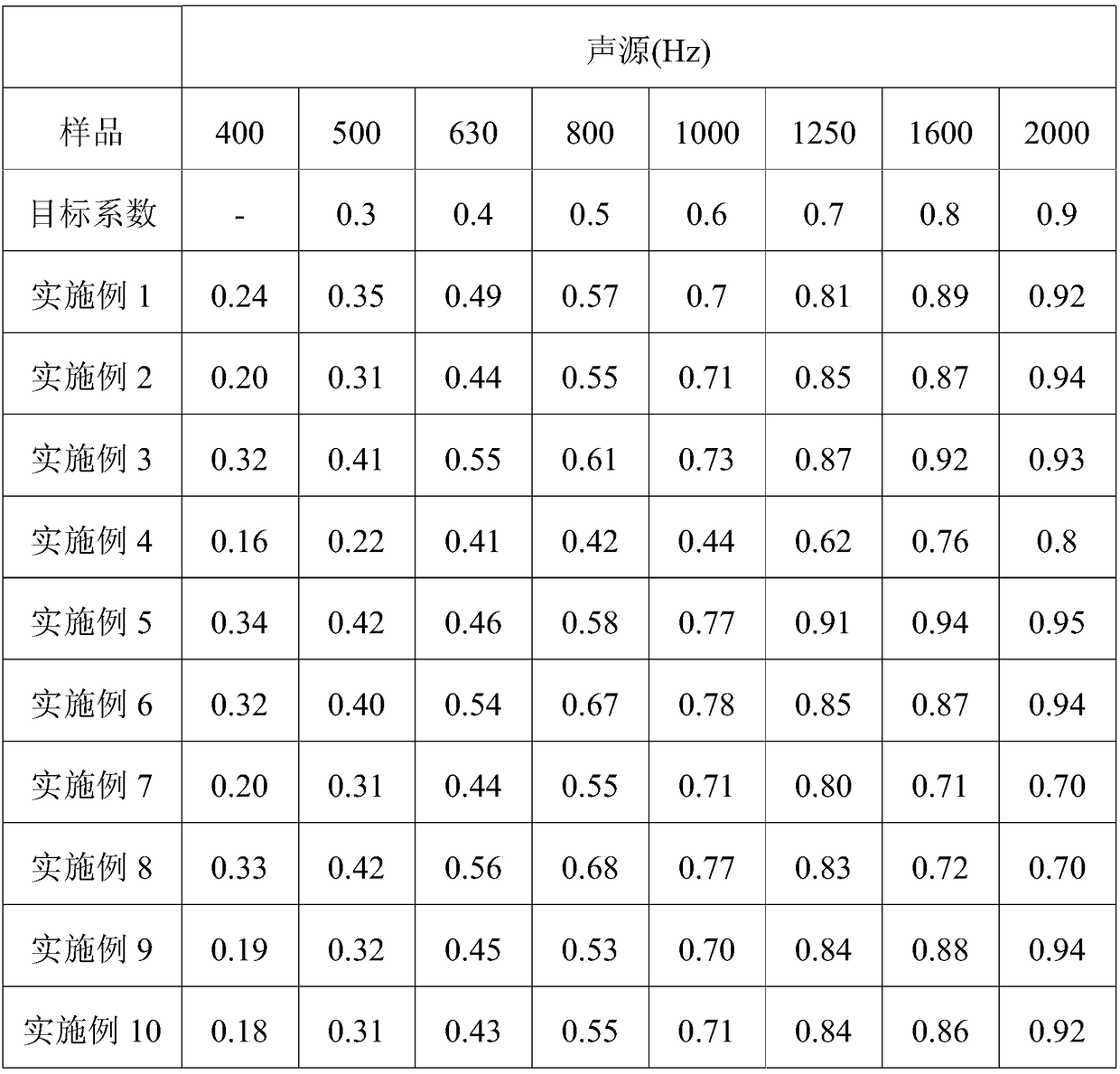

Embodiment 2-4

[0083] The only difference from Example 1 is that in this example, the thickness of the non-woven needle-punched glass fiber reinforced polypropylene layer is 4mm (Example 2), 10mm (Example 3), 2mm (Example 4), 12mm (Example 5).

Embodiment 6-16

[0085] The difference with embodiment 1 is only that, in this embodiment, the thickness of thermoplastic film layer is 0.2mm (embodiment 6), 0.04mm (embodiment 7), 0.4mm (embodiment 8);

[0086] The only difference with embodiment 1 is that in this embodiment, the aperture of the through hole provided on the thermoplastic film layer is 0.01mm (embodiment 9), 0.1mm (embodiment 10), 0.005mm (embodiment 11), 0.2mm (embodiment 12);

[0087] The only difference with Example 1 is that in this example, the porosity of the through holes provided on the thermoplastic film layer is 3% (Example 13), 10% (Example 14), 1% (Example 15) , 12% (embodiment 16).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com