Preparation method of CoN3@N-C composite electrocatalyst

A technology of electrocatalyst and preparation process, applied in catalyst activation/preparation, carbon preparation/purification, chemical instruments and methods, etc., to achieve the effect of high specific surface area, good acidic ORR and alkaline ORR performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Weigh 9.850g of dimethylimidazole into a beaker, add 100ml of absolute methanol and 100ml of absolute ethanol, stir until the dimethylimidazole is dissolved and evenly dispersed in the solution.

[0020] (2) Weigh 0.611g Co(NO 3 ) 2 ·6H 2 O and 8.118g Zn(NO 3 ) 2 ·6H 2 O in the beaker, ie Co(NO 3 ) 2 ·6H 2 O and 8.118g Zn(NO 3 ) 2 ·6H 2 The mass ratio of O is 7:93, add 100ml of absolute methanol and 100ml of absolute ethanol, stir until the solid dissolves and disperses evenly.

[0021] (3) Mix the solutions of step (1) and step (2), and stir quickly until the mixture is uniform, then seal with a parafilm, settle at room temperature for 20 hours, and then filter and wash the solution in the beaker , drying the obtained purple solid for 12 hours to obtain the Zn-Co-ZIF metal-organic framework material.

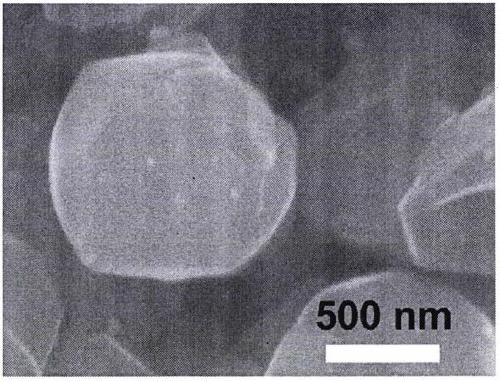

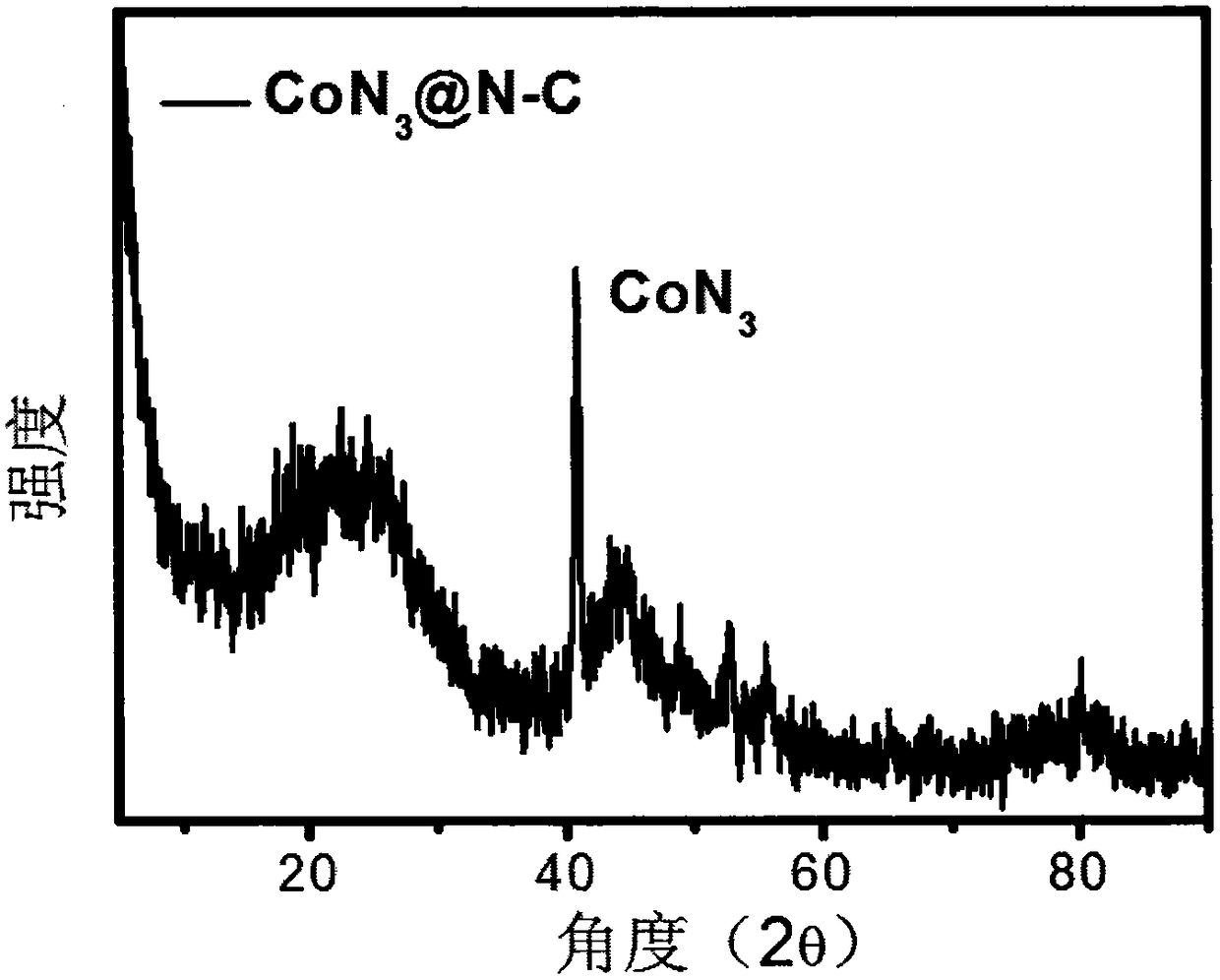

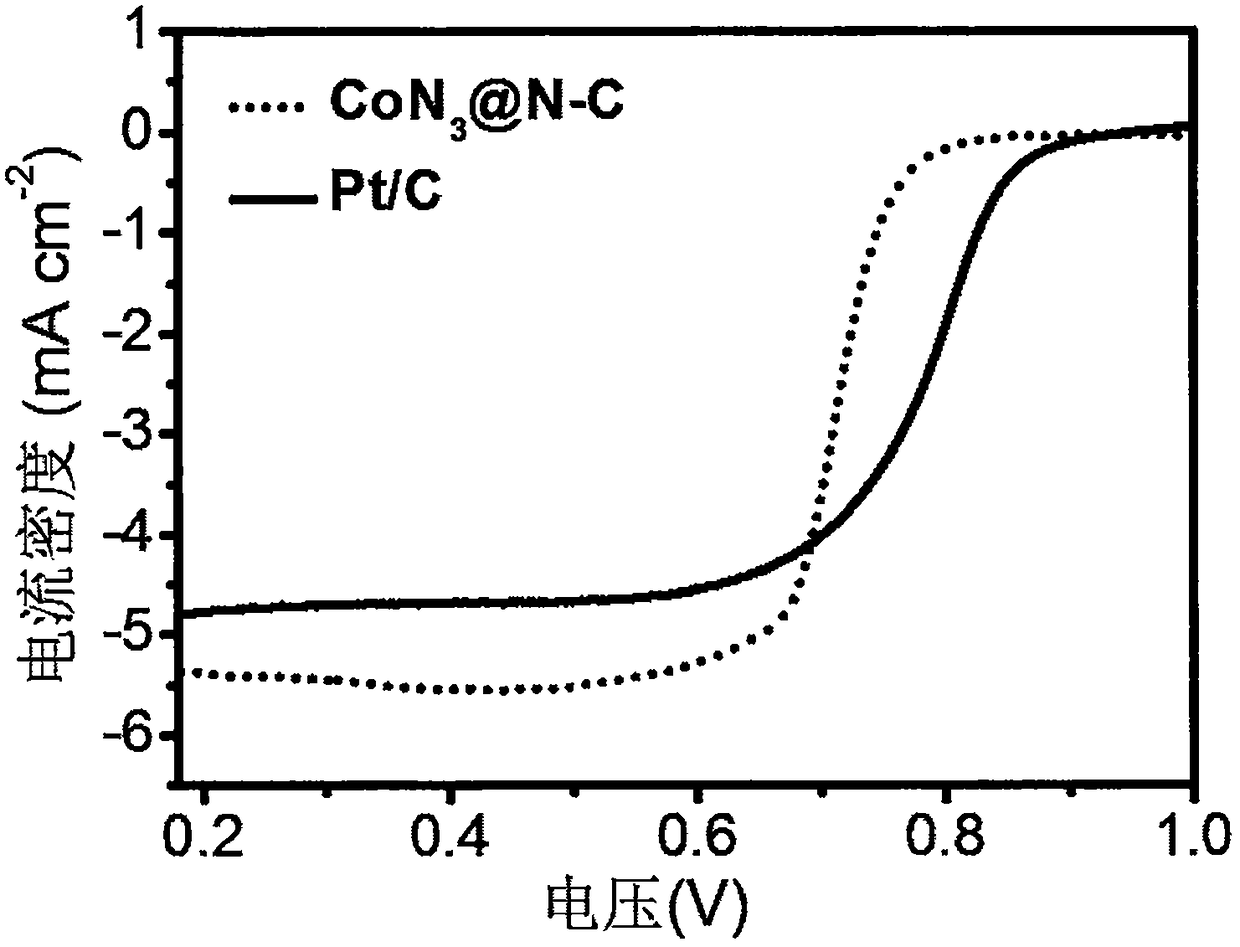

[0022] (4) Transfer the purple solid obtained in step (3) to a tubular atmosphere furnace for carbonization at 1000°C under an argon atmosphere, with a h...

Embodiment 2

[0025](1) Weigh 9.850g of dimethylimidazole into a beaker, add 100ml of absolute methanol and 100ml of absolute ethanol, stir until the dimethylimidazole is dissolved and evenly dispersed in the solution.

[0026] (2) Weigh 0.436g Co(NO 3 ) 2 ·6H 2 O and 8.293g Zn(NO 3 ) 2 ·6H 2 O in the beaker, ie Co(NO 3 ) 2 ·6H 2 O and 8.118g Zn(NO 3 ) 2 ·6H 2 The mass ratio of O is 5:95, add 100ml of absolute methanol and 100ml of absolute ethanol, stir until the solid dissolves and disperses evenly.

[0027] (3) Mix the solutions of step (1) and step (2), and stir quickly until the mixture is uniform, then seal with a parafilm, settle at room temperature for 20 hours, and then filter and wash the solution in the beaker , drying the obtained purple solid for 12 hours to obtain the Zn-Co-ZIF metal-organic framework material.

[0028] (4) Transfer the purple solid obtained in step (3) to a tubular atmosphere furnace and carry out carbonization at 1000°C, 1050°C, and 1100°C under ...

Embodiment 3

[0031] (1) Weigh 9.850g of dimethylimidazole into a beaker, add 100ml of absolute methanol and 100ml of absolute ethanol, stir until the dimethylimidazole is dissolved and evenly dispersed in the solution.

[0032] (2) Weigh 0.611g Co(NO 3 ) 2 ·6H 2 O and 8.118g Zn(NO 3 ) 2 ·6H 2 O in the beaker, ie Co(NO 3 ) 2 ·6H 2 O and 8.118g Zn(NO 3 ) 2 ·6H 2 The mass ratio of O is 7:93, add 100ml of absolute methanol and 100ml of absolute ethanol, stir until the solid dissolves and disperses evenly.

[0033] (3) Mix the solutions of step (1) and step (2), and stir quickly until the mixture is uniform, then seal with a parafilm, settle at room temperature for 20 hours, and then filter and wash the solution in the beaker , drying the obtained purple solid for 12 hours to obtain the Zn-Co-ZIF metal-organic framework material.

[0034] (4) Transfer the purple solid obtained in step (3) to a tubular atmosphere furnace for carbonization at 1000°C under an argon atmosphere, with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com