α-fe 2 o 3 Fabrication of nano-microsphere hydrogen sulfide sensitive materials and components

A technology of nano-microspheres and hydrogen sulfide, which is applied in the fields of analysis of materials, material resistance, nanotechnology, etc., can solve the problems of large amount of ionic liquid and high preparation cost, and achieve uniform morphology, good dispersibility, synthesis and post-processing methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] First add 2.0 mmol FeCl 3 ·6H 2 O and 0.05-0.1 mmol [C 12 mim][PF 6 ] mixed and dissolved in 35 mL of water, and magnetically stirred for 60 min; the resulting mixture was transferred to a 30-50 mL stainless steel self-pressurized reactor with a polytetrafluoroethylene liner, sealed, and kept at 150-210 °C React for 8-12 hours. Naturally cooled to room temperature and centrifuged to obtain a red iron oxide precursor.

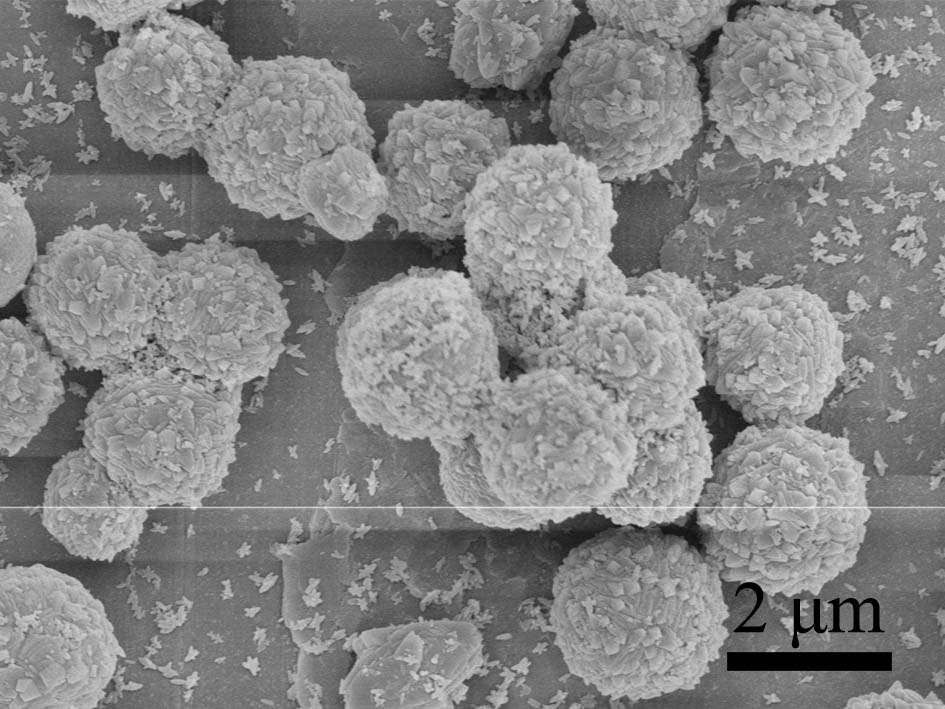

[0023] The precursor was washed several times with ultrapure water and ethanol, and then dried in vacuum at 80 °C for 12 hours. The scanning electron microscope image of the powder is as follows: Figure 1-2 shown. It can be seen from the figure that the precursor is a monodisperse nanosphere with a diameter of about 2 μm, and a rough spherical structure formed by self-assembly and accumulation of nanoparticles with a particle size of 20-100nm.

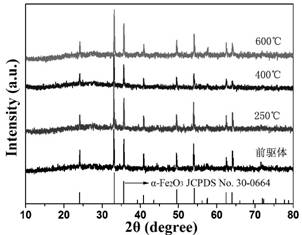

[0024] The XRD patterns obtained after the precursors were heat-treated at 250, 400 and 600 °C for 2 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com