Negative ion mineral wool board and preparation method thereof

A technology of negative ion mineral powder and mineral wool board, which is applied in the field of building materials, can solve the problems of increased production cost, material waste, and hindrance to flocculation, and achieve the effect of solving low flocculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

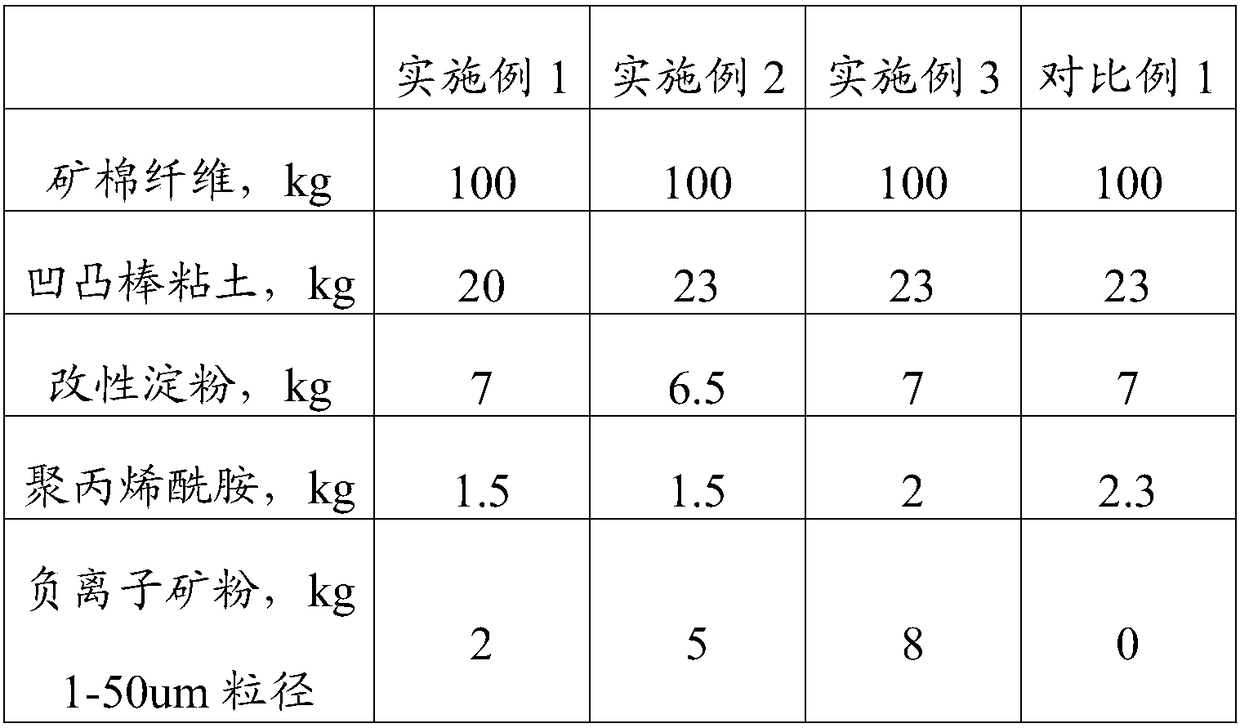

Embodiment 1-3 and comparative example 1

[0038] Step 1: Weigh each raw material according to the mass given in Table 1.

[0039] Step 2: Activate the attapulgite clay: calcinate the attapulgite clay in a muffle furnace at 280° C. for 2 hours, cool to room temperature, grind it in a mortar, and pass through a 200-mesh sieve.

[0040] Step 3: Dissolve negative ion mineral powder and activated attapulgite clay powder in water, disperse ultrasonically at a fixed power of 980W for 10 minutes, and mix evenly; filter, dry at 45°C, grind, and keep for use.

[0041] Step 4: Dilute polyacrylamide with water to a 15% by mass solution.

[0042] Step 5: After fully stirring the attapulgite clay, polyacrylamide aqueous solution, mineral wool fiber and modified starch that are loaded with negative ion mineral powder with water in the mixer, output to the feeder, and the solid content of the mixed slurry is 4-6% by mass.

[0043] Step 6: Put the above-mentioned mixed slurry on the fourdrinier wire, take it into shape by wet method...

Embodiment 4-5

[0051] Examples 4-5 differ from Example 3 only in the temperature of the activated attapulgite clay. The temperatures for activating the attapulgite clay in Examples 4-5 were 250°C and 270°C, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com