Production process of LED streetlamp shell

A technology for LED street lamps and manufacturing processes, applied in clay products, applications, household appliances, etc., can solve problems such as poor weathering and aging resistance, internal circuit short-circuit failure, product weight, etc., to improve the light reflection effect and softness, good The effect of heat dissipation and insulation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

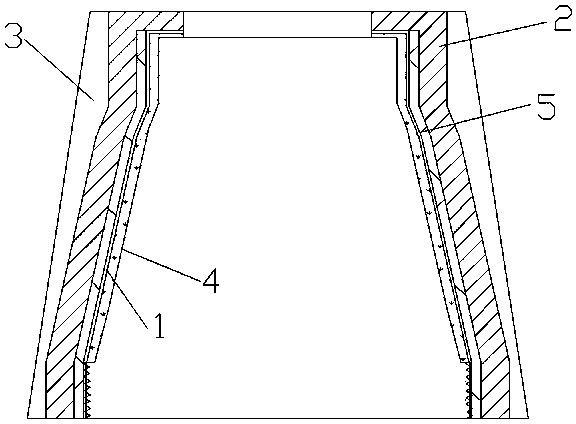

Embodiment 1

[0026] Embodiment 1. A preparation process for an LED street lamp shell, comprising the following steps: a step of preparing a combined shell, a step of preparing a light-transmitting cover, a step of preparing a connecting lamp cap, and combining the combined shell, connecting the lamp cap and the light-transmitting The step of assembling the cover, the step of preparing the combined shell, the specific method is as follows: Step 1, 1. Select the material of the required metal material for the support shell 1 according to the demand; the metal material selected for cold rolling is copper, stainless steel or Aluminum-magnesium alloy; 2. Stretching and stamping the metal material; 3. Welding by brazing; 4. Threading the inner ring of the lower opening of the support shell 1 welded in step 3; 5. The support obtained in step 4 Ultrasonic cleaning is performed on the surface of the shell 1; 6. Dry the support shell 1 cleaned in step 3 at 65-85°C; 7. Coat the outside of the dried su...

Embodiment 2

[0027]Embodiment 2, a preparation process of an LED street lamp shell, comprising the following steps: the step of preparing a combined shell, the step of preparing a light-transmitting cover, the step of preparing a connecting lamp cap, and combining the combined shell, connecting the lamp cap and the light-transmitting The step of assembling the cover, the step of preparing the combined shell, the specific method is as follows: Step 1, 1. Select the material of the required metal material for the support shell 1 according to the demand; the metal material selected for cold rolling is copper, stainless steel or Aluminum-magnesium alloy; 2. Stretching and stamping the metal material; 3. Welding by brazing; 4. Threading the inner ring of the lower opening of the support shell 1 welded in step 3; 5. The support obtained in step 4 Ultrasonic cleaning is performed on the surface of the shell 1; 6. Dry the support shell 1 cleaned in step 3 at 65-85°C; 7. Coat the outside of the drie...

Embodiment 3

[0028] Embodiment 3, a preparation process of an LED street lamp shell, comprising the following steps: the step of preparing a combined shell, the step of preparing a light-transmitting cover, the step of preparing a connecting lamp cap, and combining the combined shell, connecting the lamp cap and the light-transmitting The step of assembling the cover, the step of preparing the combined shell, the specific method is as follows: Step 1, 1. Select the material of the required metal material for the support shell 1 according to the demand; the metal material selected for cold rolling is copper, stainless steel or Aluminum-magnesium alloy; 2. Stretching and stamping the metal material; 3. Welding by brazing; 4. Threading the inner ring of the lower opening of the support shell 1 welded in step 3; 5. The support obtained in step 4 Ultrasonic cleaning is performed on the surface of the shell 1; 6. Dry the support shell 1 cleaned in step 3 at 65-85°C; 7. Coat the outside of the dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com