Tin salt hybridized melamine cyanurate and preparation method and application thereof

A technology of hybrid melamine cyanurate and melamine cyanurate, which is applied in the direction of organic chemistry, can solve the problems of difficult flame retardancy and smoke suppression performance of polymer materials, so as to improve the effect of smoke suppression and flame retardancy, reduce the Smoke generation, expansion-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A preparation method of tin salt hybrid melamine cyanurate, the specific steps are as follows:

[0060] (1) Preparation of tin cyanurate;

[0061] (i) Mix cyanuric acid, sodium hydroxide and X uniformly and stir for 2 hours at a temperature of 45°C, where X is water;

[0062] (ii) First dissolve tin tetrachloride in water to obtain a mixed solution, and then add the mixed solution dropwise to the system of step (i), keep the temperature constant, and continue to stir for 3 hours, Y is water;

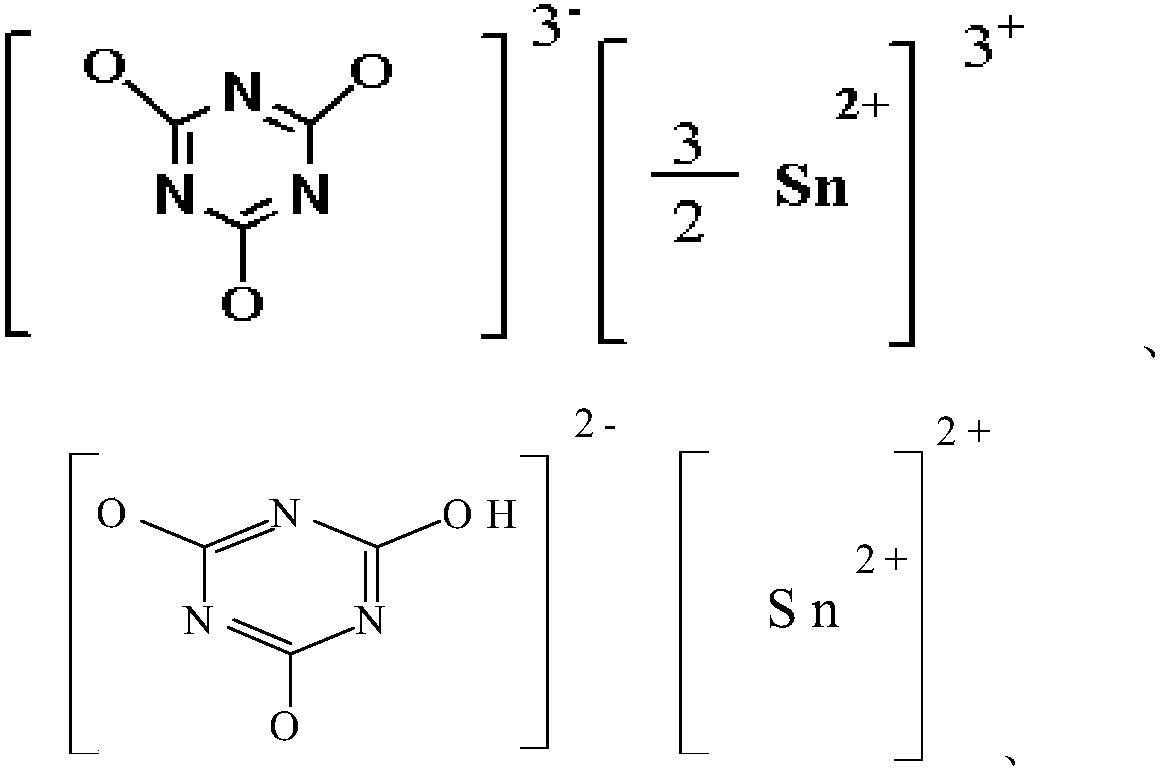

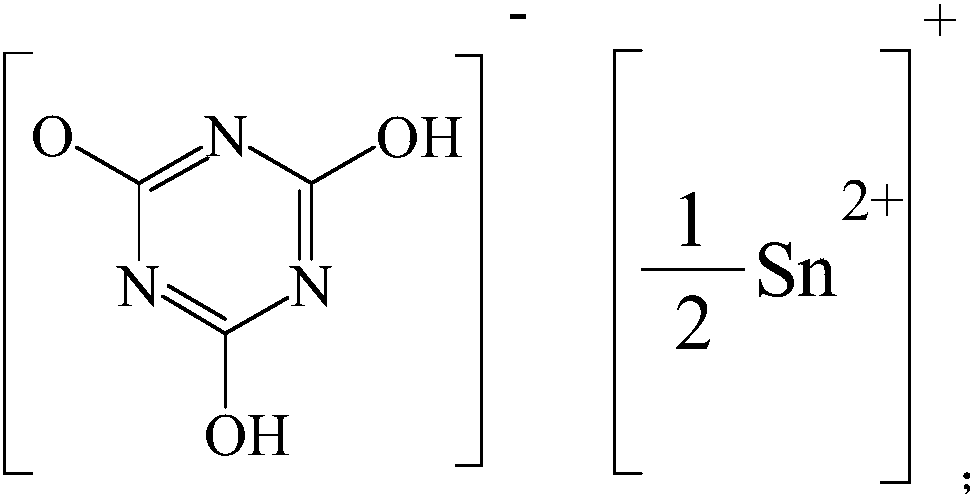

[0063] (iii) Filtering, washing and drying to obtain tin cyanurate, its structural formula is:

[0064]

[0065] In parts by weight, the addition amount of each component is:

[0066]

[0067] (2) Mix melamine, tin cyanurate and water uniformly and stir for 3 hours at a temperature of 90°C;

[0068] (3) Keep the temperature constant, add cyanuric acid to the system of step (2) and react for 5 hours;

[0069] In steps (2) and (3), the amount of each reactant added in parts by weight is as follo...

Embodiment 2

[0081] A preparation method of tin salt hybrid melamine cyanurate, the specific steps are as follows:

[0082] (1) Preparation of tin cyanurate;

[0083] (i) Mix cyanuric acid, sodium hydroxide and X uniformly and stir for 2 hours at a temperature of 60°C. The weight ratio of cyanuric acid, sodium hydroxide and ethanol is 20:5:100, and X is Ethanol

[0084] (ii) First dissolve tin tetrachloride in Y to obtain a mixed solution, and then add the mixed solution dropwise to the system of step (i), keep the temperature constant, and continue to stir for 2.5 hours, Y is ethanol;

[0085] (iii) Filtering, washing and drying to obtain tin cyanurate, its structural formula is:

[0086]

[0087] In parts by weight, the addition amount of each component is:

[0088]

[0089] (2) Mix cyanuric acid, tin cyanurate and n-amyl alcohol uniformly and stir for 2 hours at a temperature of 70°C;

[0090] (3) Keep the temperature constant, add melamine to the system of step (2) and react for 9.5 hours;

[0091...

Embodiment 3

[0096] A preparation method of tin salt hybrid melamine cyanurate, the specific steps are as follows:

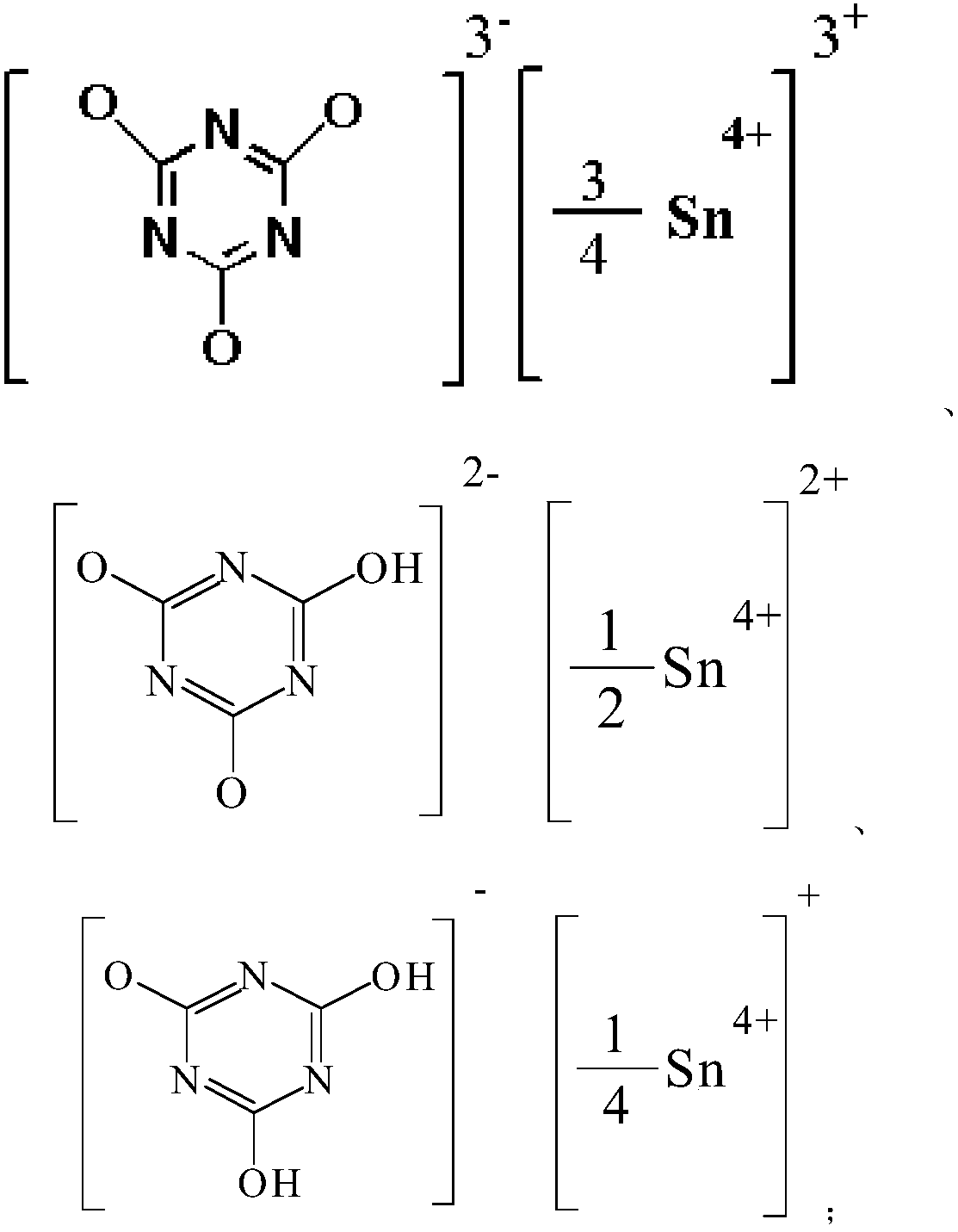

[0097] (1) Preparation of stannous cyanurate;

[0098] (i) Mix cyanuric acid, sodium hydroxide and water uniformly and stir at 40°C for 0.5 hours;

[0099] (ii) The solution obtained by dissolving stannous chloride in ethanol is added dropwise to the system of step (i), keeping the temperature constant, and continuing to stir for 2 hours;

[0100] (iii) Filtration, washing and drying to obtain stannous cyanurate, its structural formula is:

[0101]

[0102] In parts by weight, the addition amount of each component is:

[0103]

[0104] (2) Mix melamine, stannous cyanurate and methanol uniformly and stir for 2 hours at a temperature of 60°C;

[0105] (3) Keep the temperature constant, add cyanuric acid to the system of step (2) and react for 10 hours;

[0106] Wherein, in parts by weight, the amount of each component added in steps (2) and (3) is: 5 parts of stannous cyanurate; 90 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com