A method for preparing molten salt-ceramic phase change heat storage material

A technology of heat storage material and ceramic phase, which is applied in the field of preparing molten salt-ceramic phase change heat storage material, can solve the problems of low temperature range of polymer, high electrical conductivity of metal material, low high temperature structural strength, etc. The effect of using the environment range, low cost and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

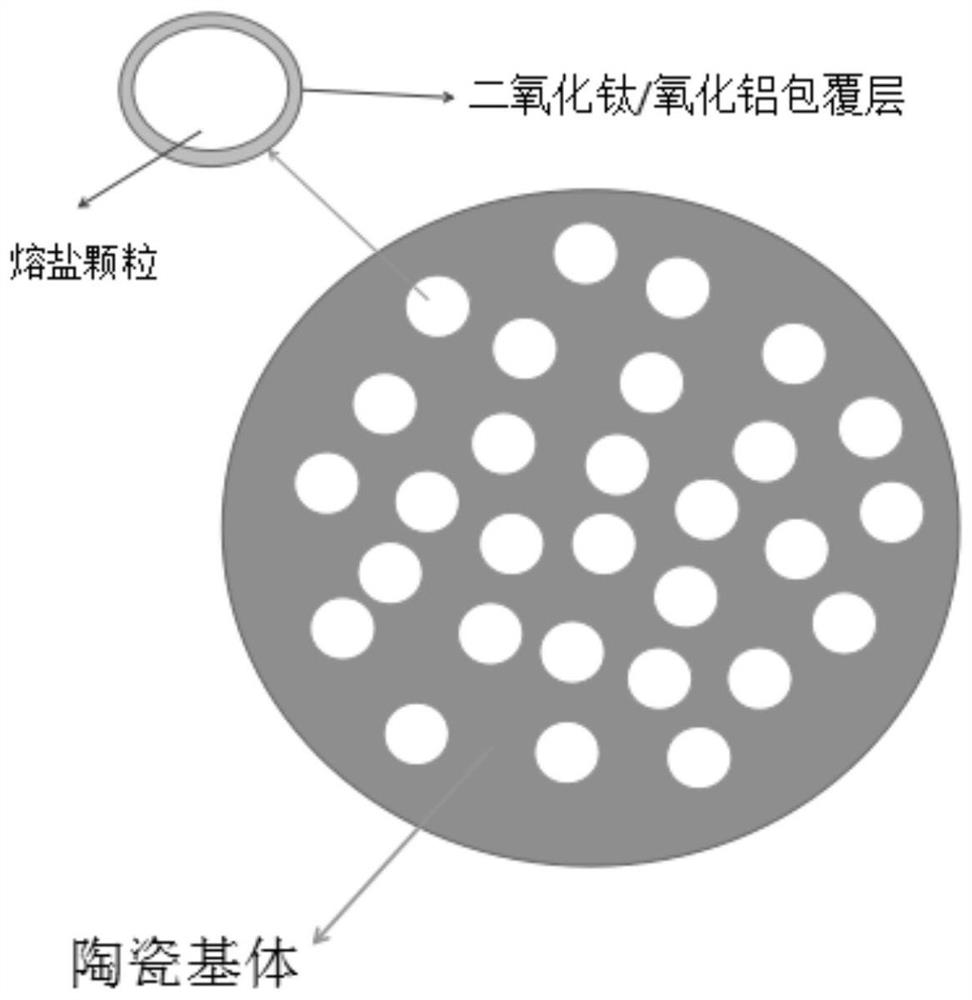

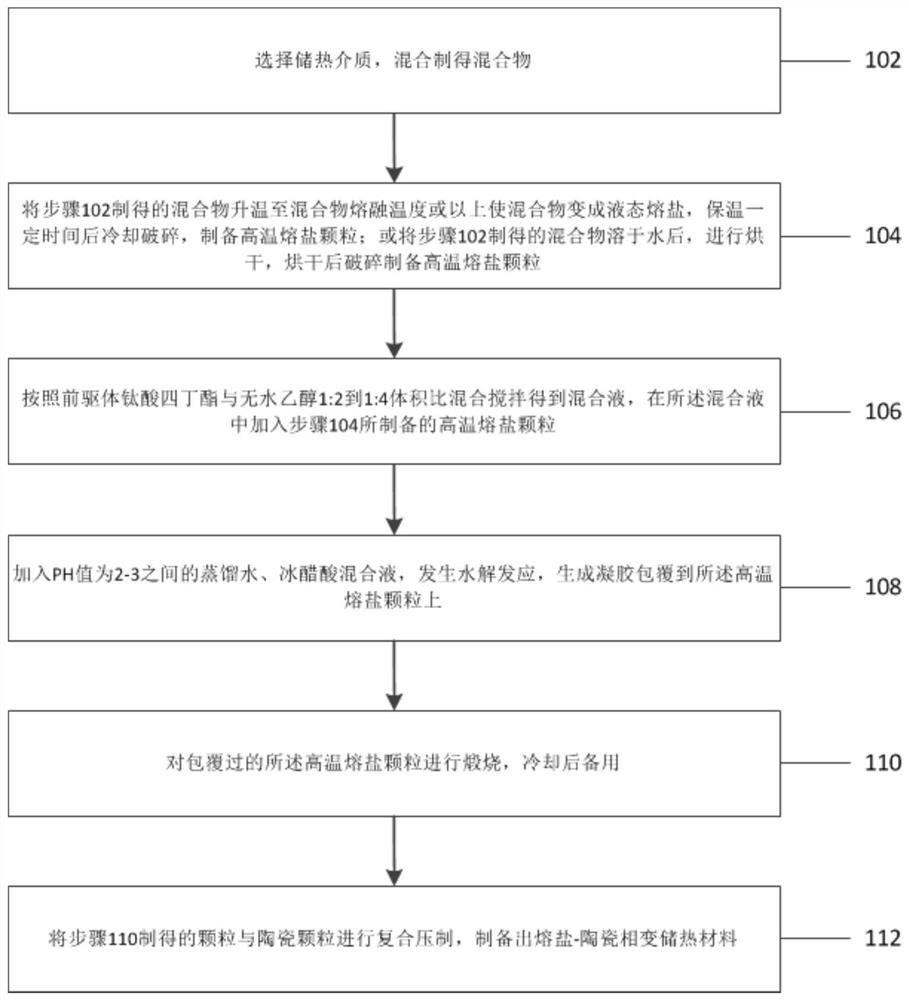

[0030] figure 2 A flow chart of a method for preparing a molten salt-ceramic phase change heat storage material according to the present invention is shown. Such as figure 2 As shown, the method for preparing molten salt-ceramic phase change heat storage material according to the present invention comprises the following steps:

[0031] Step 102, selecting a heat storage medium and mixing it to obtain a mixture;

[0032] Step 104, heating the mixture prepared in step 102 to the melting temperature of the mixture or above to turn the mixture into liquid molten salt, cooling and crushing after holding for a certain period of time to prepare high-temperature molten salt particles; or dissolving the mixture prepared in step 102 in water , drying, and crushing after drying to prepare high-temperature molten salt particles;

[0033] Step 106, mixing and stirring the precursor tetrabutyl titanate and absolute ethanol at a volume ratio of 1:2 to 1:4 to obtain a mixed solution, an...

example 1

[0038] Step 1. Preparation of high temperature molten salt particles

[0039] Step 1.1. Select Na2CO3 and K2CO3 as the heat storage medium, mix them at a ratio of 52:48, and use a ball mill to mill at a ball-to-material ratio of 1:1 at a speed of 110 rpm for 30 minutes to mix Na2CO3 and K2CO3 evenly for preparation Hydrated eutectic salt.

[0040] Step 1.2, heating the mixed mixture to 720° C. to form a molten state; keeping the temperature for 2 hours to prepare a molten eutectic salt.

[0041] Step 1.3: Crush and grind the prepared molten eutectic salt into powder, place the powder in spherical abrasives of different diameters, add a small amount of water, press with a pressure of 10Mpa, and place the compressed molten salt particles at 680°C Sintering under certain conditions to prepare molten salt particles of different particle sizes for use.

[0042] Step 2. Coating the eutectic salt particles in the sol-gel process

[0043] Step 2.1. Mix and stir the precursor tetrab...

example 2

[0051] Step 1. Preparation of high temperature molten salt particles

[0052] Step 1.1. Select Na2CO3 and K2CO3 as the heat storage medium, mix them at a ratio of 52:48, and use a ball mill to mill at a ball-to-material ratio of 1:1 at a speed of 110 rpm for 30 minutes to mix Na2CO3 and K2CO3 evenly for preparation Hydrated eutectic salt.

[0053] Step 1.2, heating the mixed mixture to 720° C. to form a molten state; keeping the temperature for 2 hours to prepare a molten eutectic salt.

[0054] Step 1.3: Crush and grind the prepared molten eutectic salt into powder, place the powder in spherical abrasives of different diameters, add a small amount of water, press with a pressure of 10Mpa, and place the compressed molten salt particles at 680°C Sintering under certain conditions to prepare molten salt particles of different particle sizes for use.

[0055] Step 2. Coating the eutectic salt particles in the sol-gel process

[0056] Step 2.1. Mix and stir the precursor tetrab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com