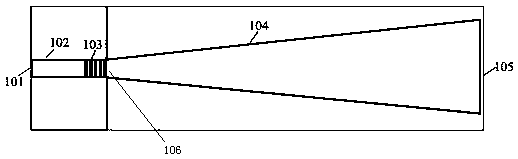

Cone semiconductor laser

A laser and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser parts, etc., to achieve the effect of increasing the length, the beam quality is not easy to deteriorate, and the high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Applications in GaAs-based 980 nm lasers:

[0022] Epitaxial structure:

[0023] The substrate layer is 350 μm, the lower confinement layer is 700 nm, the waveguide layer is 2400 nm, the upper confinement layer is 700 nm, and the contact layer is 200 nm.

[0024] Chip structure:

[0025] 1) Ridge area length: 1 mm;

[0026] 2) Ridge area width: 5 μm;

[0027] 3) Ridge etching depth: 1.0 𝛍m;

[0028] 4) Bragg mirror: etching depth 1.3 𝛍m, period 300 nm, logarithm 1000 pairs;

[0029] 5) Angle of cone area: 4 degrees;

[0030] 6) Length of tapered area: 4 mm;

[0031] 7) Etching depth of tapered area: 200 nm;

[0032] 8) Front cavity surface corrosion: ethylene glycol: 30% phosphoric acid: hydrogen peroxide = 20:5:1, corrosion depth 3.5 μm;

[0033] 9) Cavity surface coating: the reflection rate of the rear cavity surface is coated with high reflection film, and the reflection rate of the front cavity surface is 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com